Scraped-car fuel tank residual fuel recycling device and working method thereof

A recovery device and fuel tank technology, which is applied in the direction of vehicle scrap recovery, recycling technology, motor vehicles, etc., can solve the problems of complex fuel tank structure, low work efficiency, incomplete fuel recovery, etc., and achieve small footprint and automation The effect of high degree and good convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

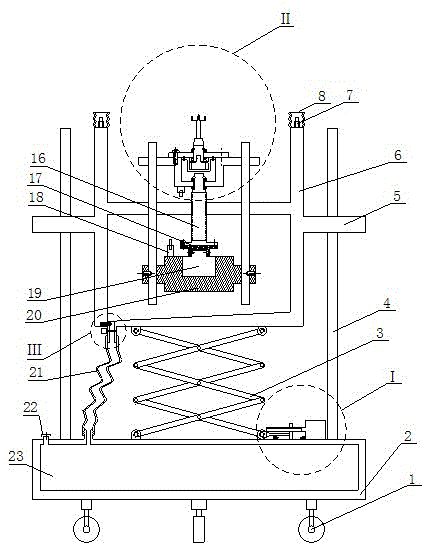

[0025] Such as figure 1 As shown, the present invention provides a fuel tank residual fuel recovery device, including: an oil receiving barrel 6, the oil receiving barrel 6 is provided with a drilling device for opening a hole at the bottom of the fuel tank, the drilling device is controlled by a The module controls the opening, and after the opening, the fuel remaining in the fuel tank flows into the oil receiving barrel 6 through the hole.

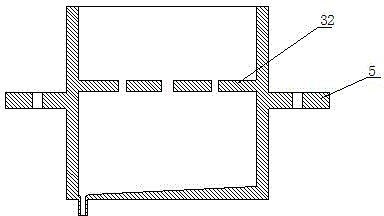

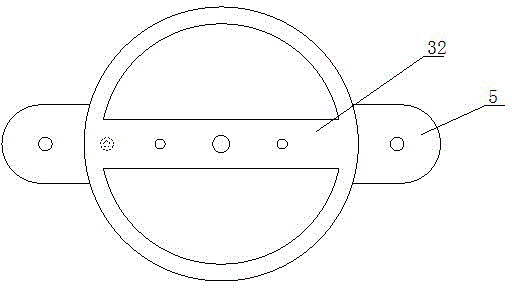

[0026] Such as diagram 2-1 with Figure 2-2 As shown, the oil receiving barrel 6 is a barrel-shaped part, with a semi-waist circular guide flange 5 on each side, and a guide hole (round shape is optional) in the middle of the guide flange, which can ensure oil connection In the direction of movement of the barrel 6, there is a long partition 32 in the oil barrel 6, and there is a guide hole (round shape can be selected) that matches with the drill lifting guide rod 10 on both sides of the partition 32. The hole can ensure the operating dir...

Embodiment 2

[0040] On the basis of Embodiment 1, the present invention also provides a working method of a fuel tank residual fuel recovery device, the fuel tank residual fuel recovery device includes: an oil barrel 6 and a drilling device controlled by a control module; The working method includes: the control module is adapted to make a hole in the bottom of the fuel tank through a drilling device, so that the remaining fuel in the fuel tank flows into the oil receiving barrel 6.

[0041] Specifically, the method in which the control module is adapted to make a hole in the bottom of the oil tank through a drilling device includes: the oil receiving barrel 6 controls the oil receiving barrel 6 to rise or descend through the oil receiving barrel 6 lifting mechanism, wherein when the oil receiving When the barrel 6 rises and the top touch switch 7 on the upper edge of the oil receiving barrel 6 is in contact with the bottom of the oil tank, the control module controls the drilling device to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com