Method and device for dismantling and recycling scrapped automobile

A technology of scrapped cars and recycling methods, which is applied in the direction of scrapped vehicles, recycling technology, motor vehicles, etc., and can solve problems such as waste oil leakage, groundwater pollution, and large secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

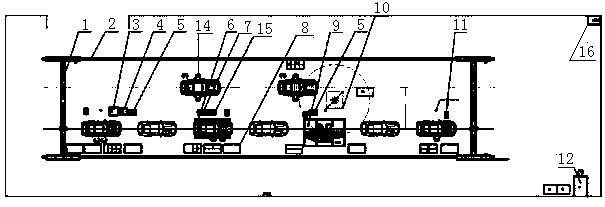

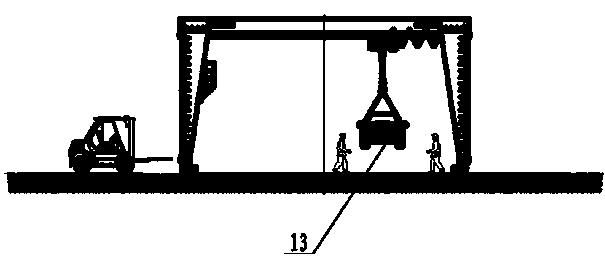

[0028] see figure 1 , figure 2 , image 3 , the dismantling and recycling method for scrapped automobiles of the present invention is: first disassemble hazardous wastes at the hazardous waste dismantling station, then send the scrapped automobiles after dismantling the hazardous wastes to the buffer station, and wait to enter the next station; The oil extraction station extracts the waste oil, and then sends the scrapped car after the waste oil extraction to the buffer station, and waits to enter the next station; the third is to disassemble the engine gearbox at the engine gearbox disassembly station, and then put the The scrapped car after the engine gearbox is disassembled is sent to the buffer station, and then enters the next station; finally, the parts are disassembled at the parts disassembly station, and then the scrapped car body is sent to the discharge station.

[0029] A dismantling and recycling equipment for scrapped automobiles, including a hazardous was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com