An automatic butt welding machine for rigid electric igniter

An electric ignition, butt welding machine technology, applied in welding equipment, welding equipment, auxiliary welding equipment and other directions, can solve the problems of poor welding consistency, affecting product quality, high labor intensity, etc., to achieve convenient clamping, ensure continuous transmission, Reduce the effect of manual labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

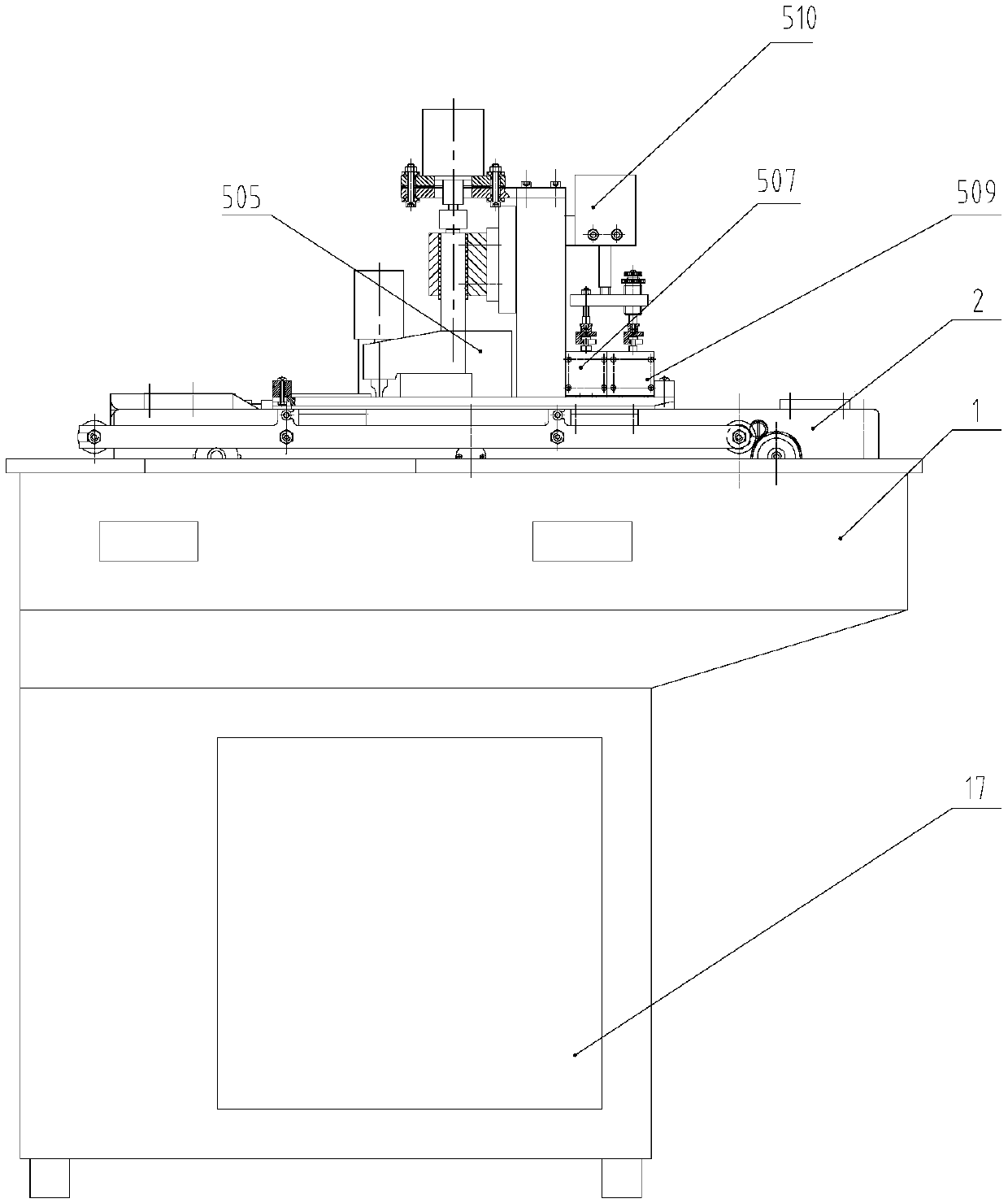

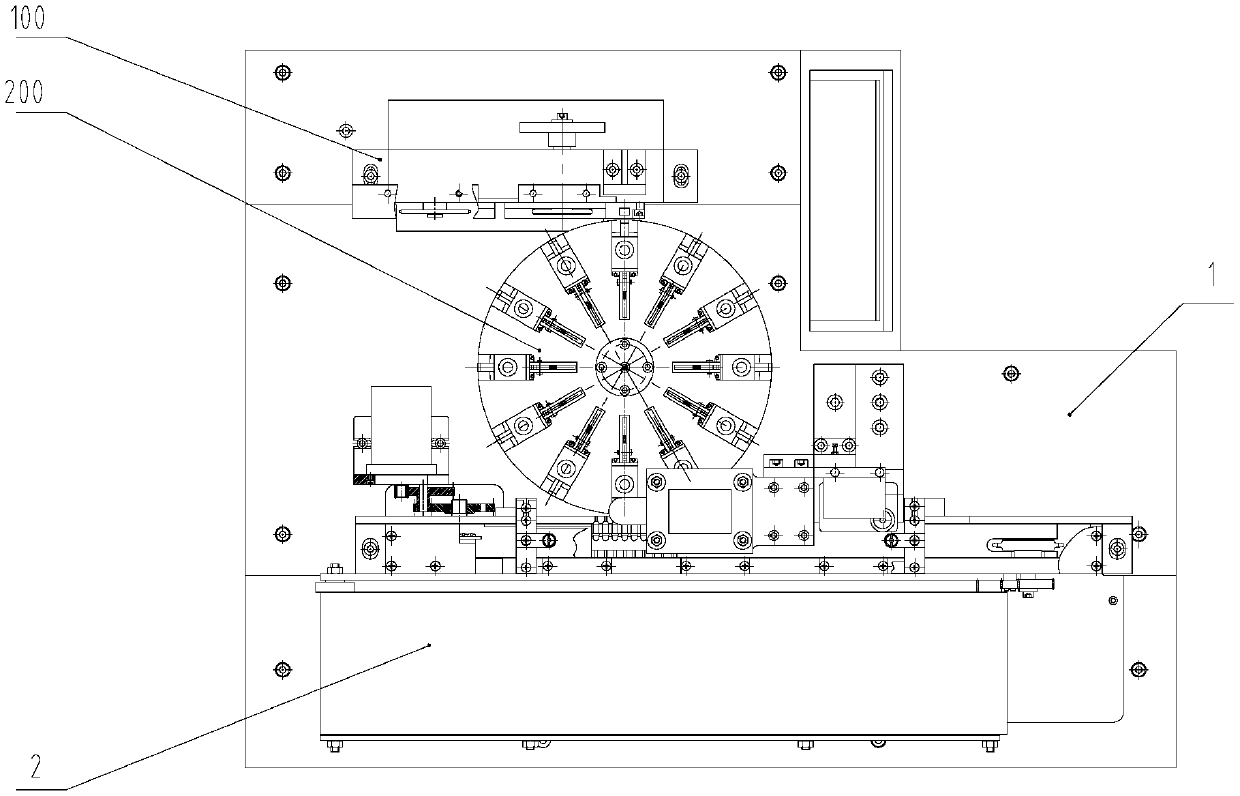

[0046] like figure 1 , figure 2 , Figure 4 and Figure 11 As shown, the present invention includes a fuselage base 17, an automatic butt welding device that is installed on the fuselage base 17 and automatically welds the bridge head and the bridge plug leg line in the electric ignition element, and monitors the automatic butt welding device. monitoring device;

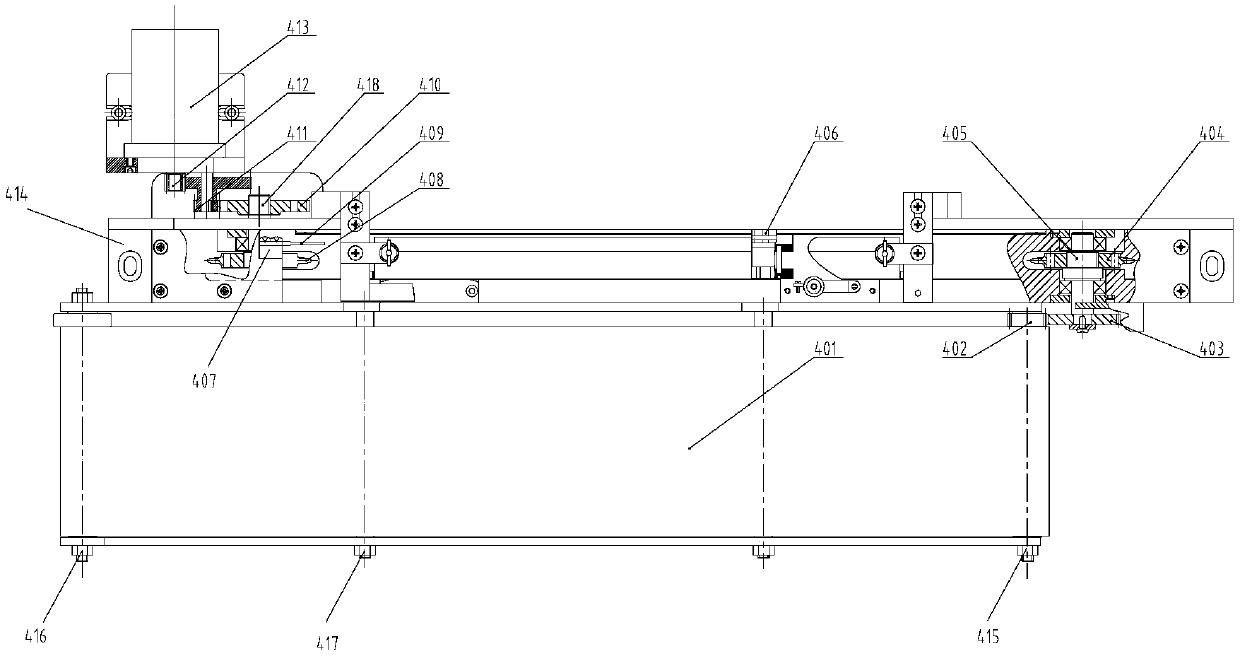

[0047] The automatic butt welding device includes a horizontally arranged workbench 1, a bridge plug transmission mechanism for continuously transmitting bridge plug legs, a bridge head transmission mechanism for continuously transmitting bridge heads, and an electrode mechanism for welding bridge heads and bridge plug legs , and an unloading mechanism for unloading the welded electric ignition element from the bridge plug conveying mechanism;

[0048] The bridge plug transmission mechanism includes a bridge plug guide rail transmission mechanism 2 installed on the workbench 1 to transmit the bridge plug leg lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com