Clamping tool convenient for double-sided machining

A technology of clamping tooling and double-sided processing, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of reduced parallelism of processing surfaces, reduced production efficiency, and easy changes in positioning references, etc., to achieve improved The effect of work efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

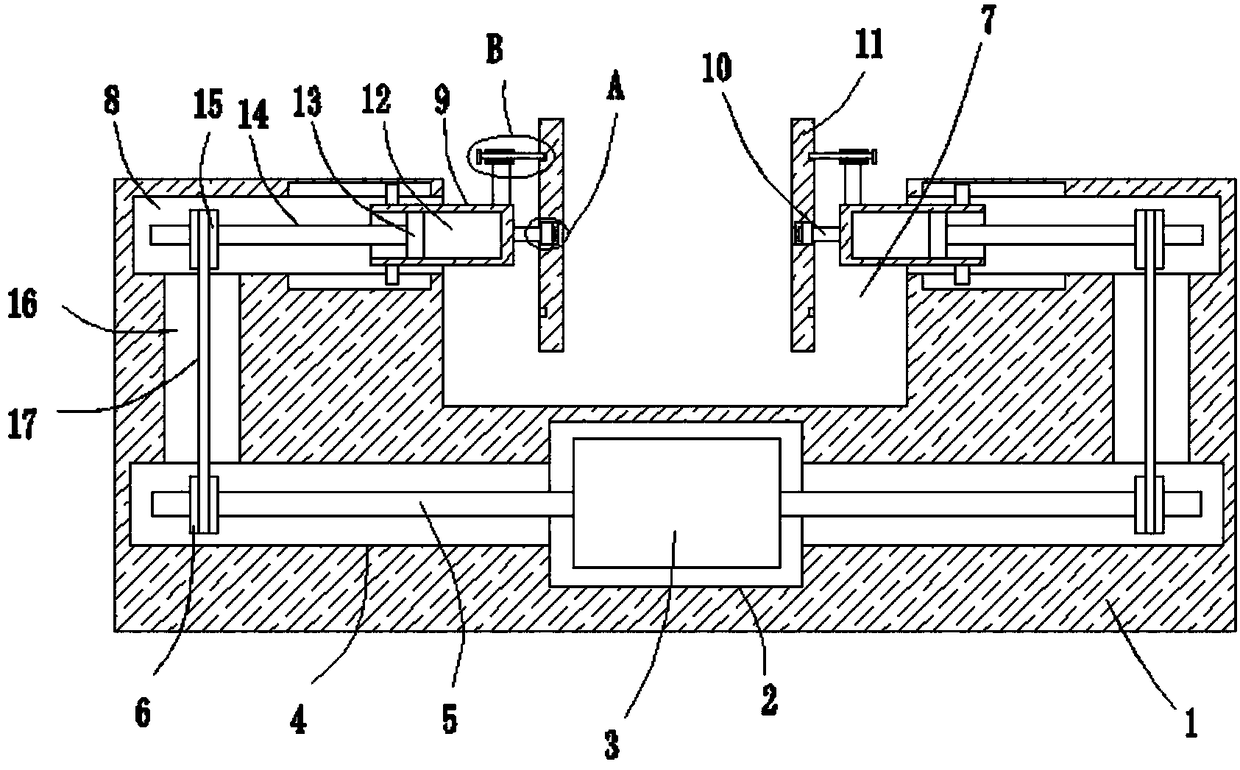

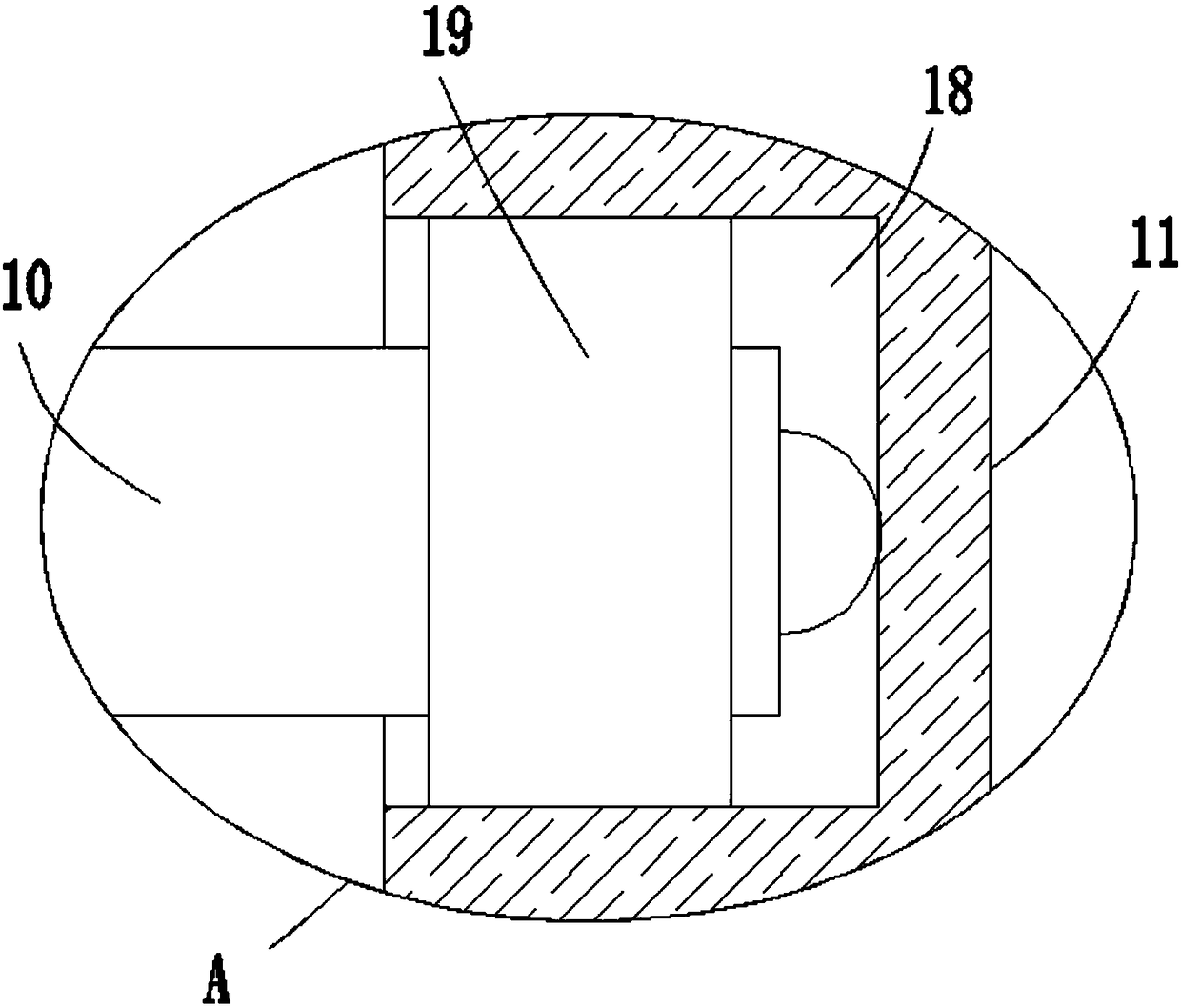

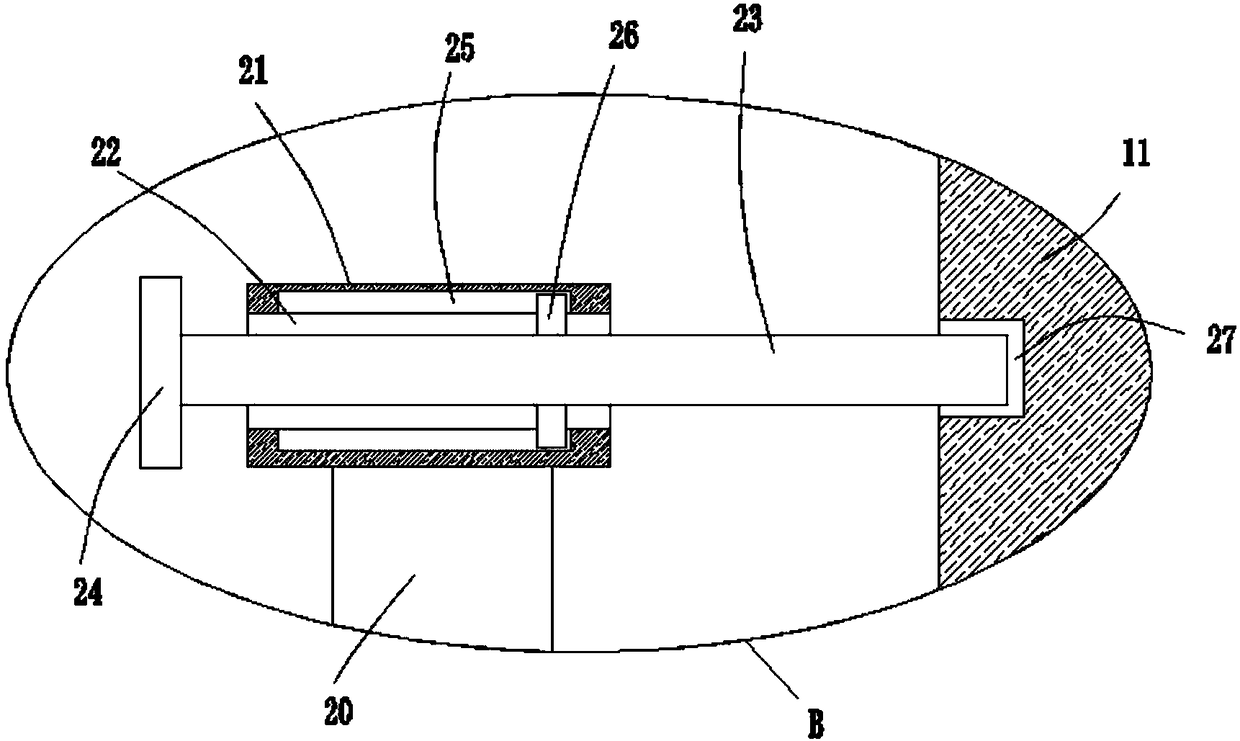

[0022] refer to Figure 1-5 In this embodiment, a clamping tool for double-sided processing is proposed, including a base 1, a motor cavity 2 is opened on the base 1, a motor 3 is fixedly installed in the motor cavity 2, and the inner walls of both sides of the motor cavity 2 are A rotating slot 4 is opened, and a rotating shaft 5 is installed in the rotating slot 4. The end of the rotating shaft 5 close to the motor chamber 2 extends into the motor chamber 2 and is fixedly connected with the output shaft of the motor 3. The first gear is fixedly sleeved on the rotating shaft 5 6. The top side of the base 1 is provided with a through groove 7, and the inner walls of both sides of the through groove 7 are provided with a chute 8, and a slide rod 9 is slidably installed in the chute 8, and the end of the slide rod 9 close to the through groove 7 extends to A connecting rod 10 is fixedly installed in the through groove 7, and a chuck 11 is installed on the side where the two conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com