Lifting type centering clamping device and clamping method thereof

A clamping device and lift-type technology, applied in the field of lift-type centering clamping devices, can solve the problems of affecting efficiency, limited opening angle of the clamping opening, troublesome adjustment, etc. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

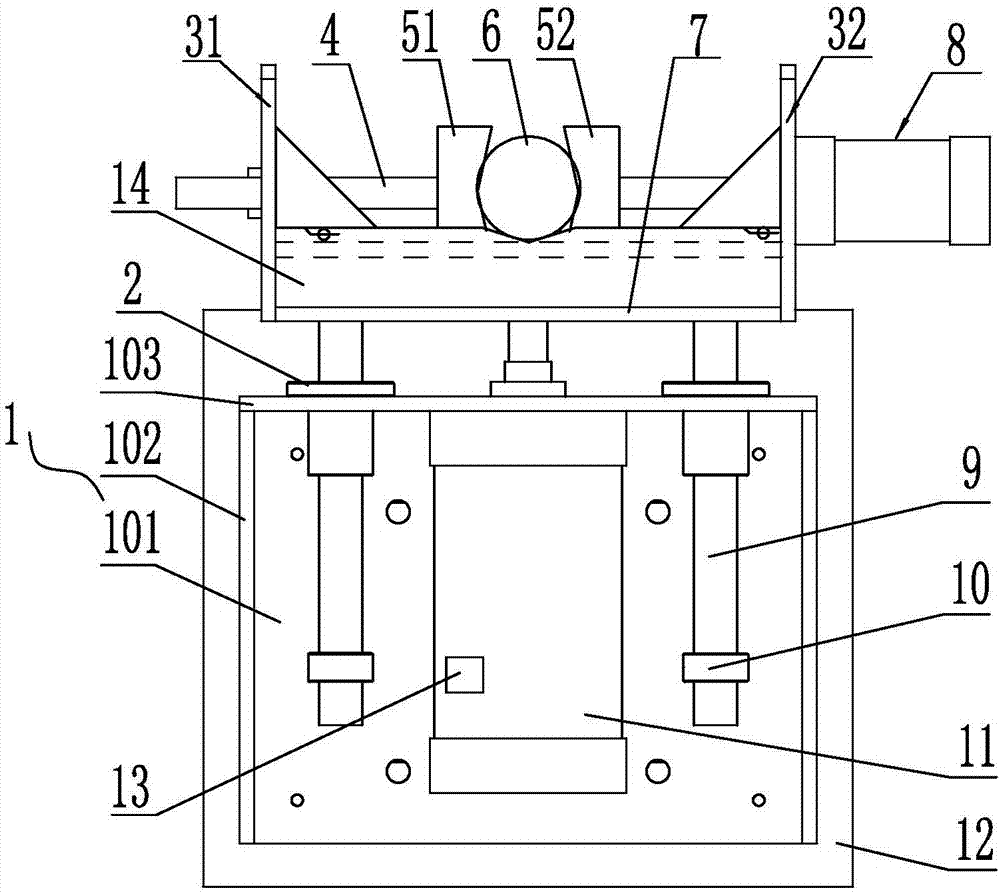

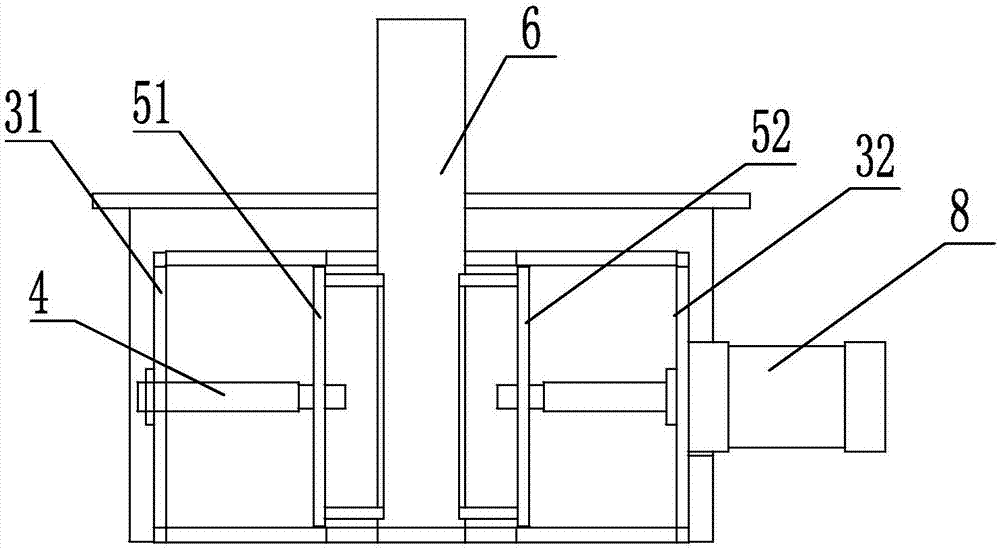

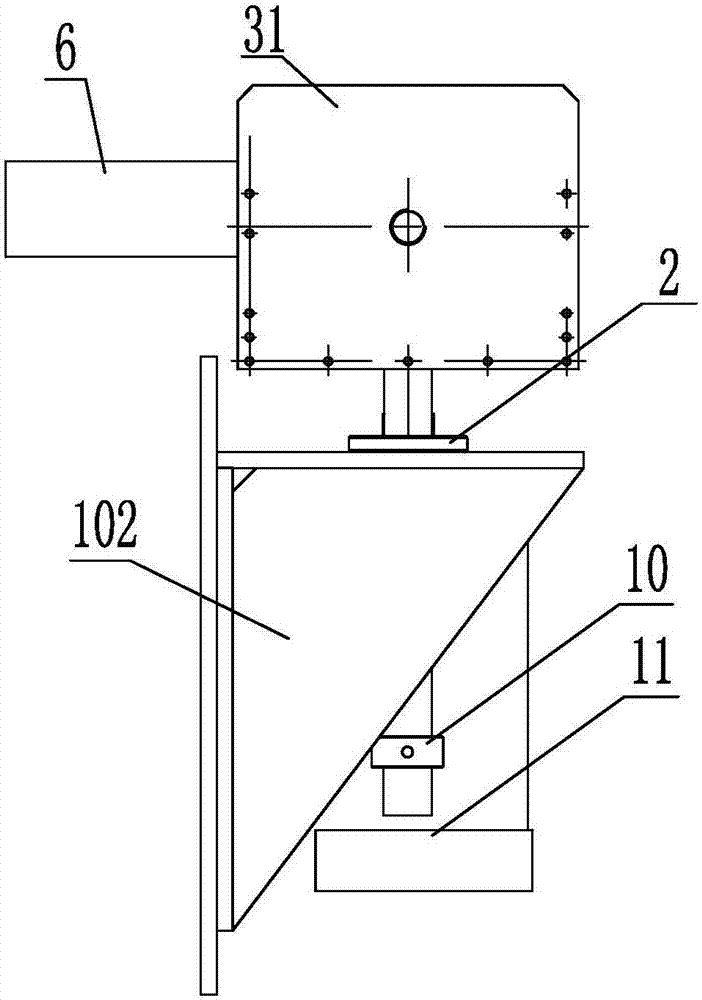

[0040] A lift-type centering clamping device, including a centering clamping mechanism and a lifting mechanism, the centering clamping mechanism is an "open-loop" clamping mechanism, including a bottom plate 7, a clamping cylinder 8, and sequentially symmetrically installed on The left connecting plate 31, the right connecting plate 32, the left clamping plate 51 and the right clamping plate 52 on the left and right sides of the bottom plate, the left clamping plate and the right clamping plate are relatively installed to form an “open-loop” clamping port, and the left connecting plate and the right connecting plate are respectively installed on On the outside of the left and right splints, the left connecting plate is connected to the screw mandrel by an outer hex nut 41, the other end of the screw rod is connected to the left splint, and the clamping cylinder 8 is installed on the outside of the right connecting plate, and the piston rod of the clamping cylinder stretches into...

Embodiment 2

[0048] A production line composed of several lift-type centering clamping devices. According to production needs, multiple sets of lift-type centering clamping devices are arranged on both sides of the conveyor chain, and each pair of opposite sets forms a group. Automatic conveying equipment The circular workpiece is sent to the first group for centering and clamping through the conveyor chain, and then sent to the second group after processing, and so on.

Embodiment 3

[0050] A clamping method of a lifting centering clamping device, comprising the following steps:

[0051] S1 initial adjustment:

[0052] S11 adjusts the left and right and horizontal position of the left splint through the outer hexagon nut 41 according to the diameter of the circular workpiece, and then fixes the outer hexagon nut;

[0053] S12 adjusts the lifting stroke of the lifting cylinder 11 through the limit cylinder 10, so that when the lifting cylinder is fully raised, the center of the circular workpiece and the thimble of the processing equipment are kept at the same level;

[0054] S13 Adjust the left and right positions of the vertical panel 101 through the horizontal long slot through hole of the lifting cylinder mounting plate 12, so that the center of the semicircular arc hole in the middle of the side plate of the chuck slot is on the same line as the thimble of the processing equipment;

[0055] S2 clamping, the automatic conveying equipment horizontally t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com