Energy storage type parking unit brake cylinder

A unit brake cylinder and parking brake technology, which is applied in the direction of brake actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of parking cylinders that cannot be inflated, inconvenient installation, loss of function, etc., to achieve reliability and safety High, small footprint, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with the embodiment that accompanying drawing provides.

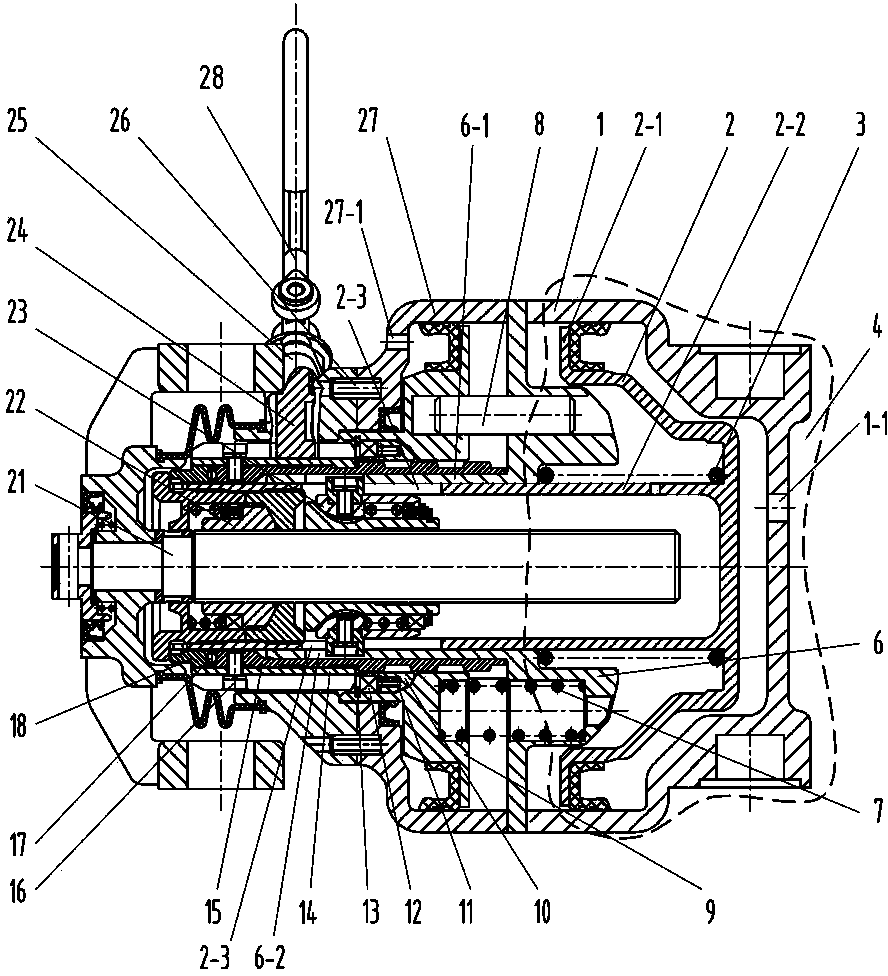

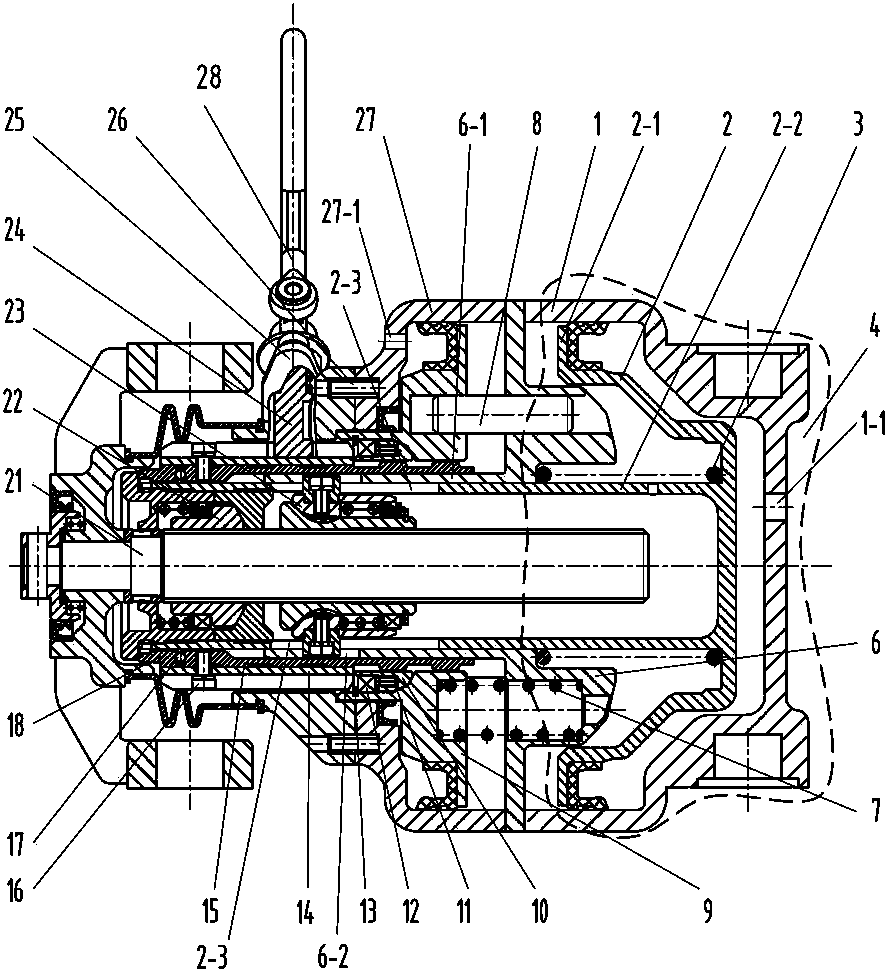

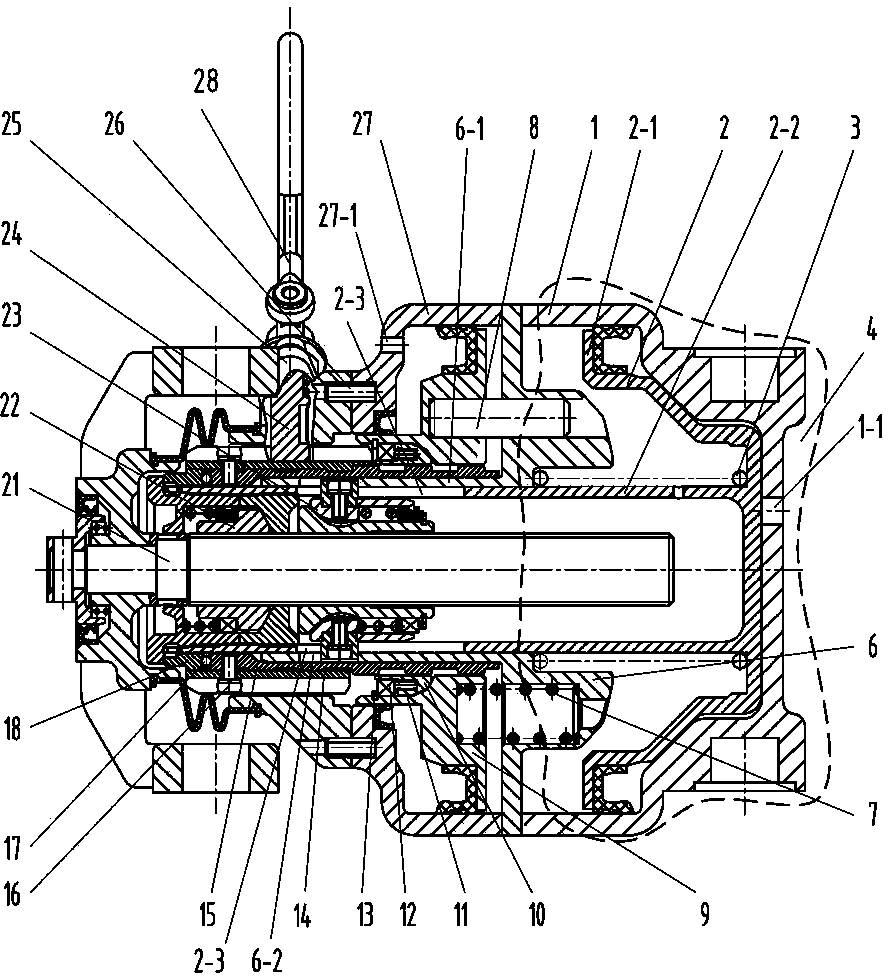

[0036] like Figure 1~12As shown, an energy storage type parking unit brake cylinder of the present invention includes two parts, a unit brake cylinder part and a parking brake cylinder part, and the unit brake cylinder part includes a brake cylinder 4, a reset mechanism 21 and a gap Adjusting mechanism, the brake cylinder 4 includes a brake cylinder 1 provided with a first air inlet 1-1 and a brake piston 2 arranged in the brake cylinder 1, and the brake piston 2 includes a The piston body 2-1 fitted on the inner wall of the moving cylinder body 1 and the piston tube 2-2 extending from the middle of the piston body 2-1 to one side; one end of the brake cylinder body 1 is fixedly connected with an intermediate body 6, and the intermediate body 6 A relief spring 3 is provided between the piston body 2-1 of the brake piston 2; The inner wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com