Shell-class machine tool fixture

A technology of machine tool fixtures and shells, which is applied in the field of tooling fixtures, and can solve problems such as increased storage costs, increased number of fixtures, and inconvenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

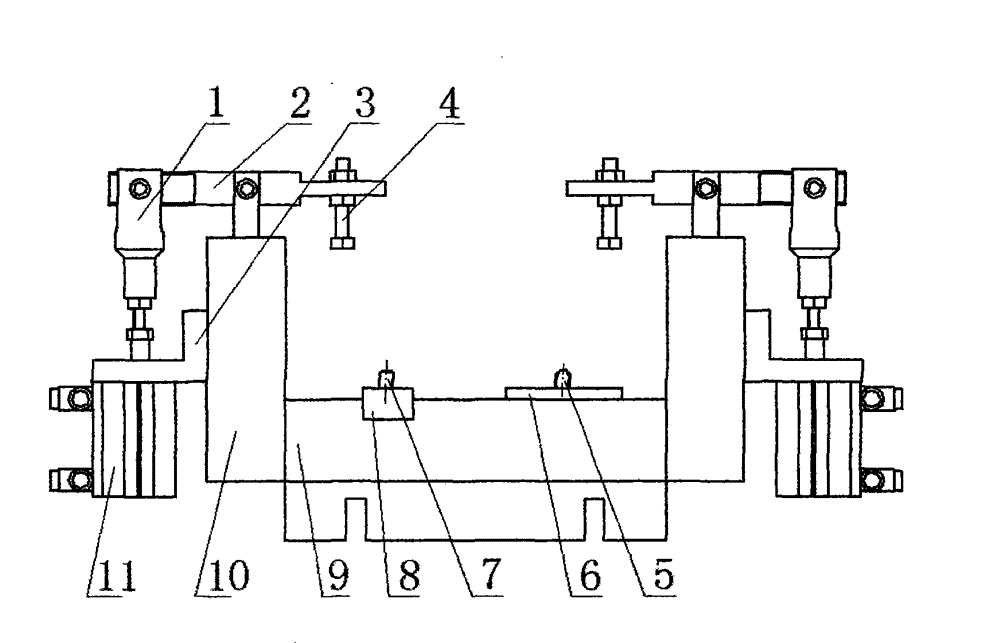

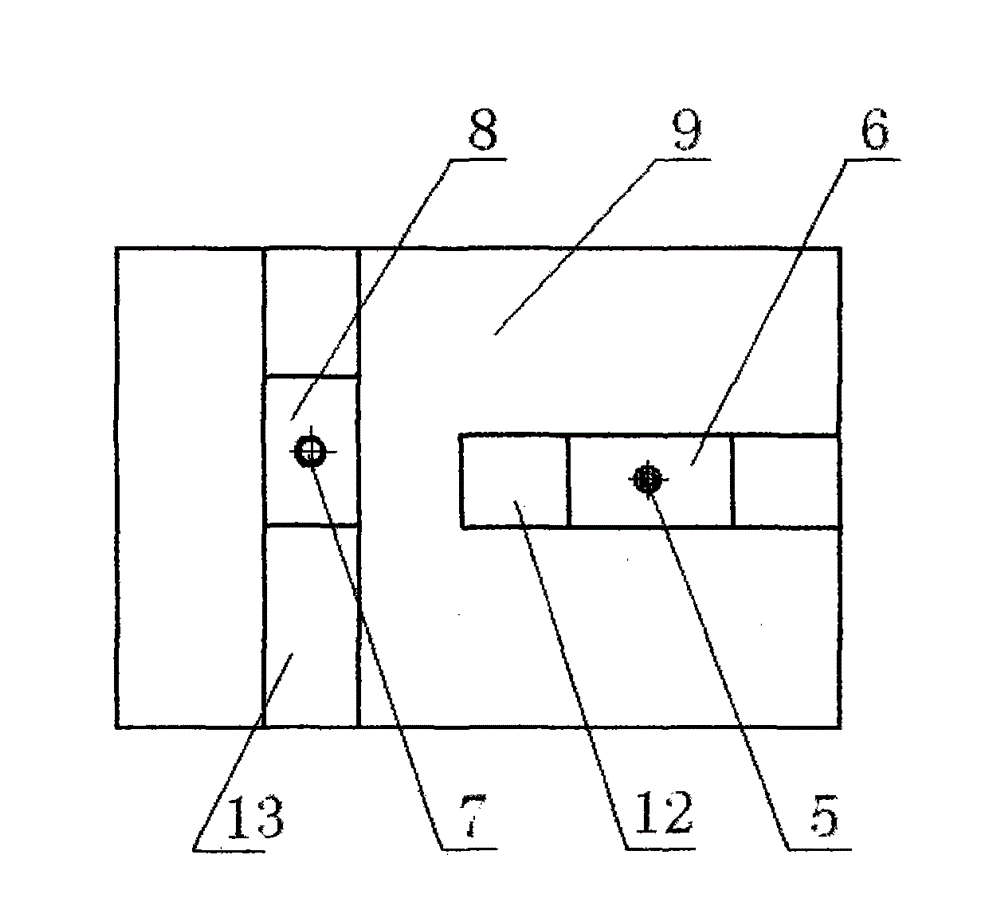

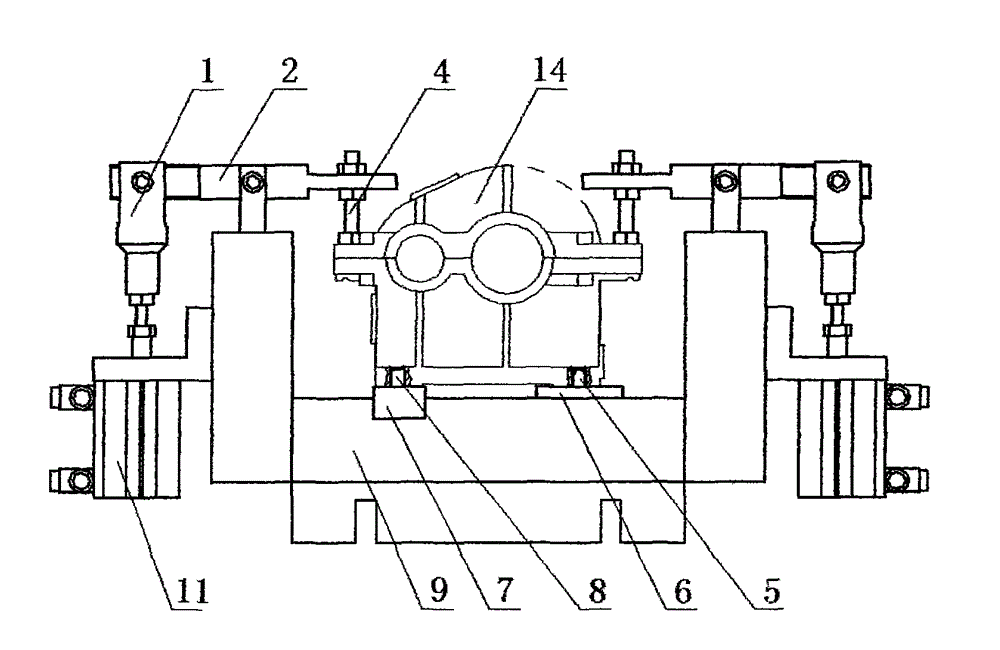

[0018] Such as figure 1 , figure 2 As shown, the shell-type machine tool fixture includes a base 9, a fixture positioning part and a clamping mechanism, and the fixture positioning part includes a cylindrical pin 7, a chamfering pin 5, a first support plate 6 with a positioning plane, and a second support plate with a positioning plane. Two supporting plates 8, the trimming pin 5 is fixedly connected with the first supporting plate 6, the cylindrical pin 7 is fixedly connected with the second supporting plate 8, the clamping mechanism is located above the base 9, and the upper surface of the base 9 has a first guide groove 12 And the second guide groove 13 perpendicular to the first guide groove 12, the first guide groove 12 has a displaceable first support plate 6, and the second guide groove 13 is provided with a displaceable second support plate 8. Both sides of the base 9 have fixed support blocks 10 respectively, and the clamping mechanism has a symmetrical shell clampi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com