Automatic pipe machining machine

A technology of automatic processing and pipe fittings, which is applied in the direction of metal processing machinery parts, metal processing, metal processing equipment, etc., can solve the problems that cannot meet the actual requirements, the length of pipe fittings is different, and the efficiency is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053]In conjunction with the accompanying drawings, the following is further described:

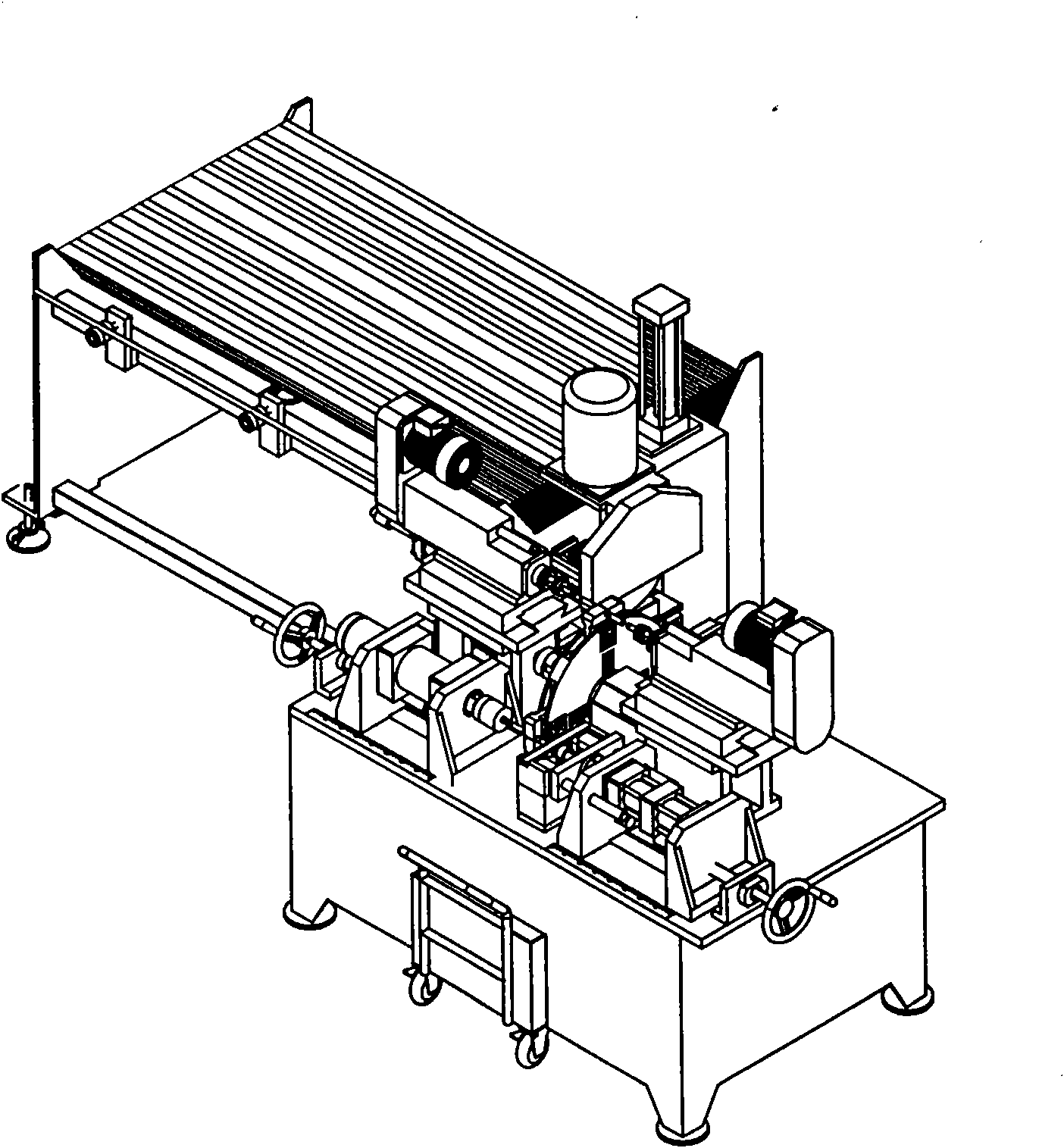

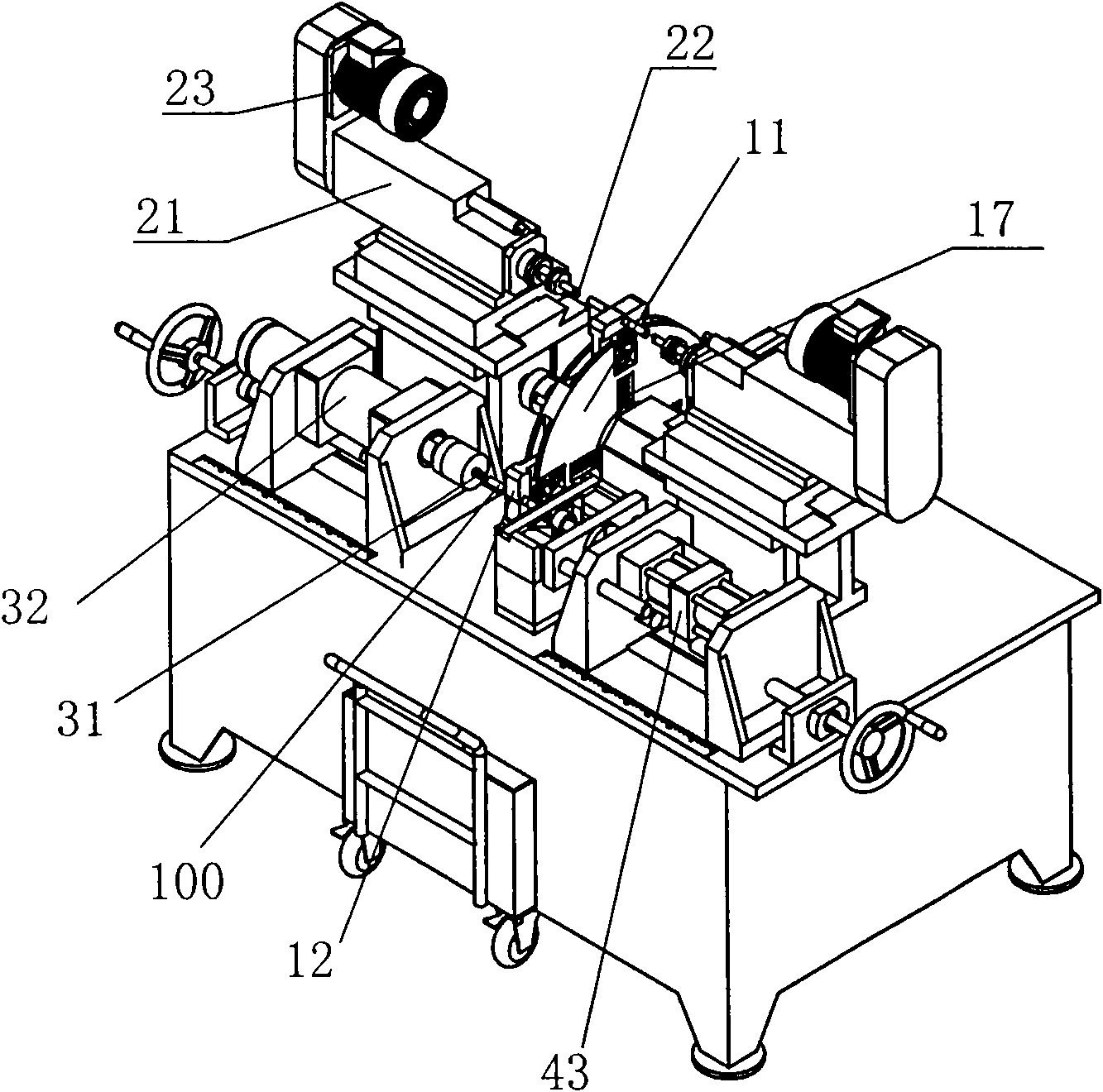

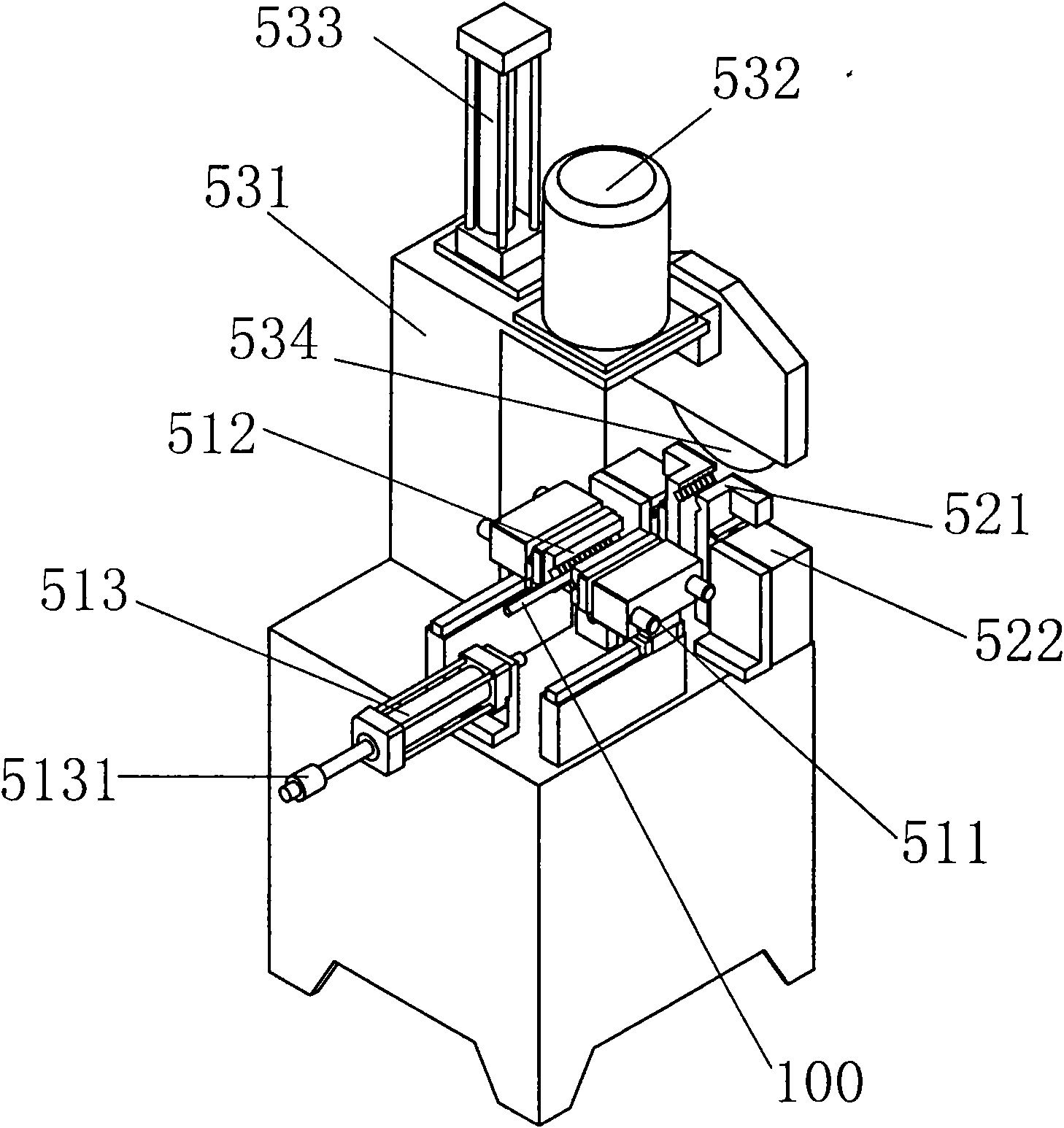

[0054] An automatic processing machine for pipe fittings, characterized in that it includes a transposition device capable of clamping pipe fittings and realizing transposition, and chamfering devices, pipe expanding and punching devices respectively located at the periphery of the transposition mechanism, wherein:

[0055] 1) The transposition device (such as figure 2 , Figure 4 As shown), it includes a rotating disk 11 and a servo motor that drives the rotating disk to rotate and shift. Four clamping mechanisms for clamping pipes are uniformly arranged on the circumference of the rotating disk. When three of the clamping mechanisms correspond to the For the cutting device, chamfering device and pipe expanding and punching device, another clamping mechanism corresponds to the pipe outlet, each clamping mechanism has a pair of clamping jaws 12, and a telescopic rod 13 that drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com