Drilling clamp for oil hole of bent axle in adjustable position

A crankshaft oil hole and drilling fixture technology, which is used in boring/drilling, positioning devices, drilling/drilling equipment, etc., can solve the problems of frequent fixture replacements, high manufacturing costs, and difficult placement accuracy. To achieve the effect of convenient and flexible adjustment method, low manufacturing cost and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings:

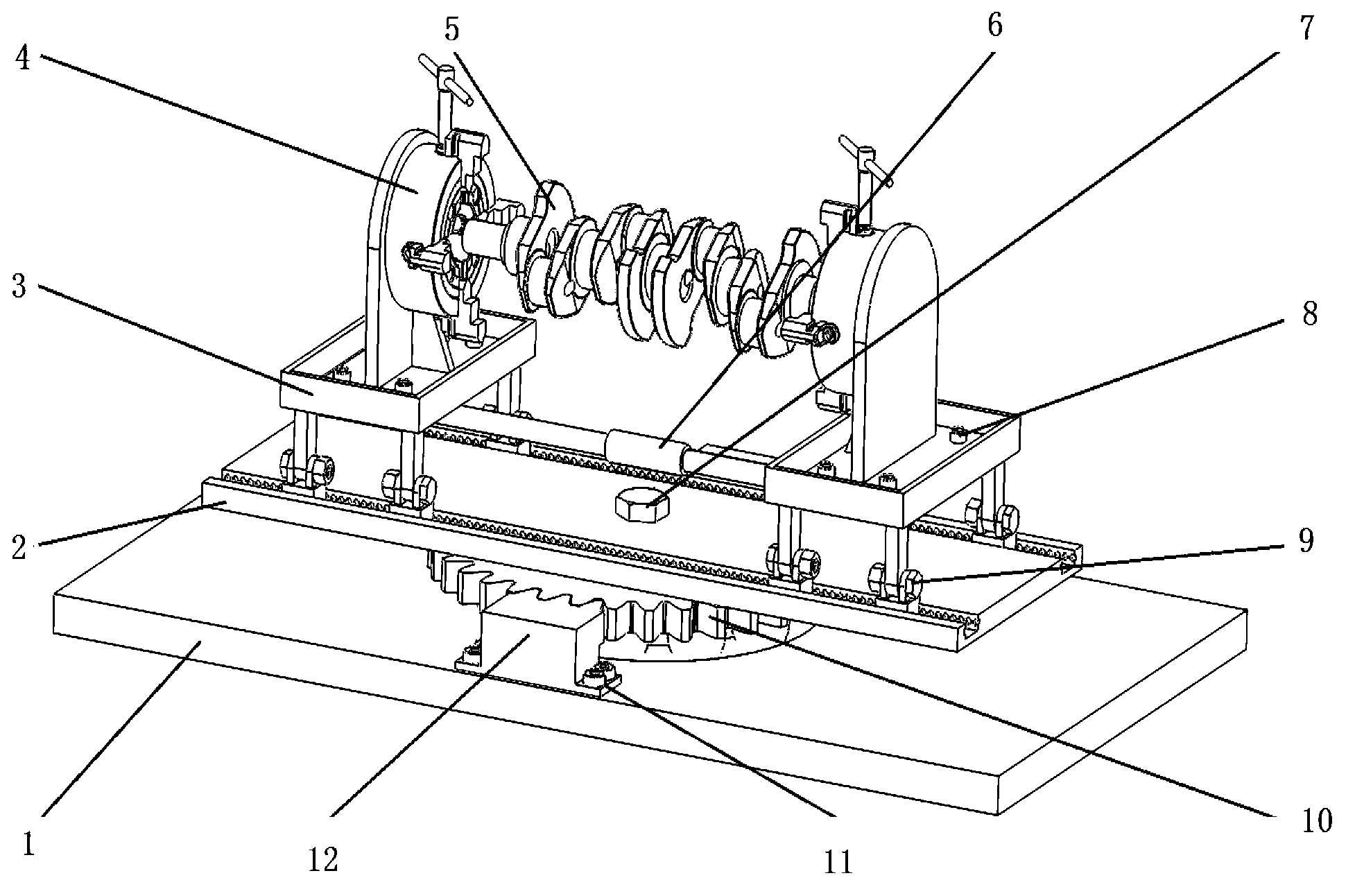

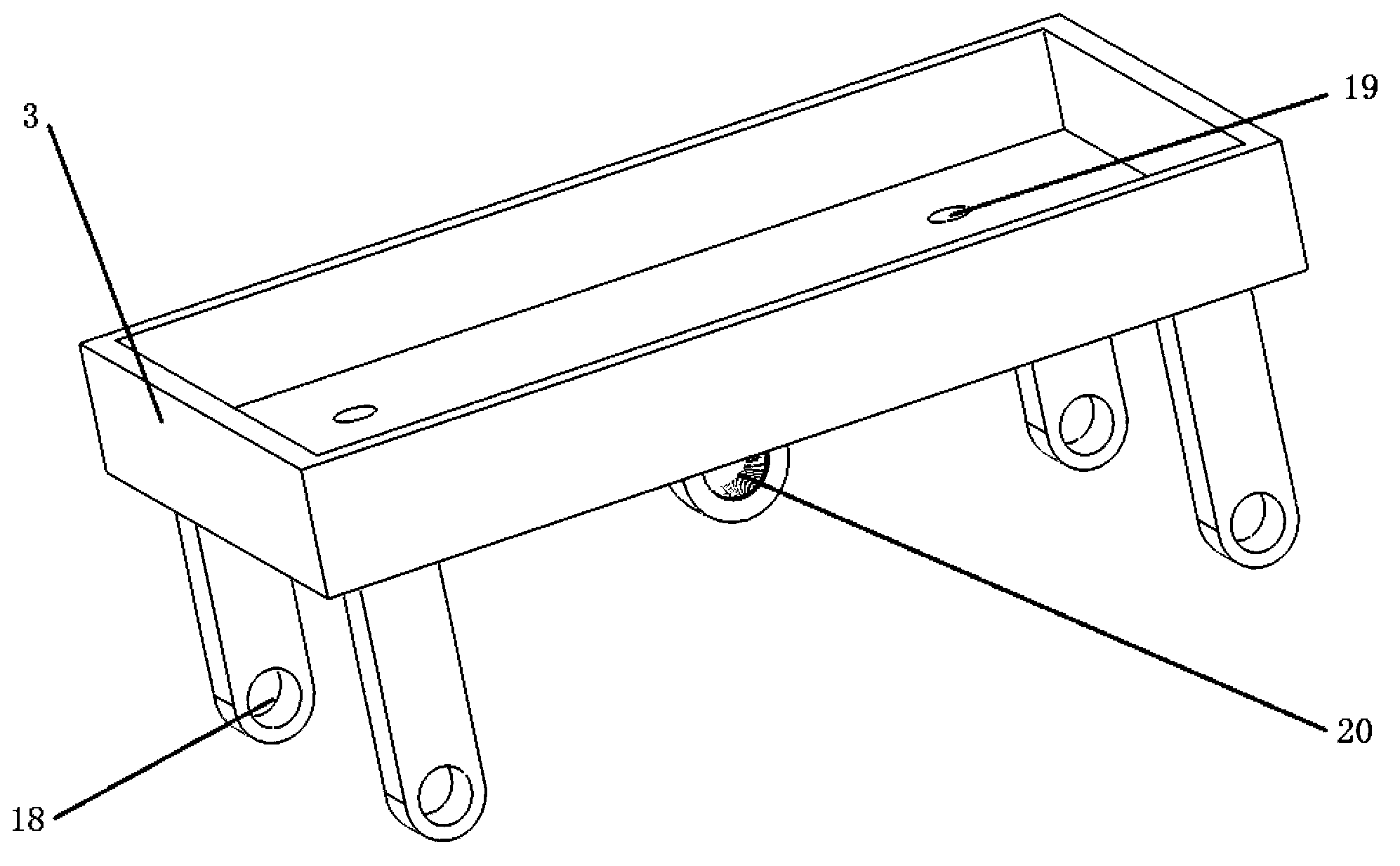

[0030] Such as figure 1 As shown, the position-adjustable crankshaft oil hole drilling jig mainly includes a support base 1, a guide plate 2, a clamp body 3, an N-jaw chuck 4 (a four-jaw chuck is used in the embodiment), an adjusting screw rod 6, and an angle adjusting gear 10 And positioning mechanism 12. The clamping mechanism clamps and fixes the crankshaft 5 on the clamp body 3 . The clamping mechanism and the position adjustment mechanism are fixedly connected with screws 8, and the positioning mechanism and the support base are fixedly connected with fastening screws 11.

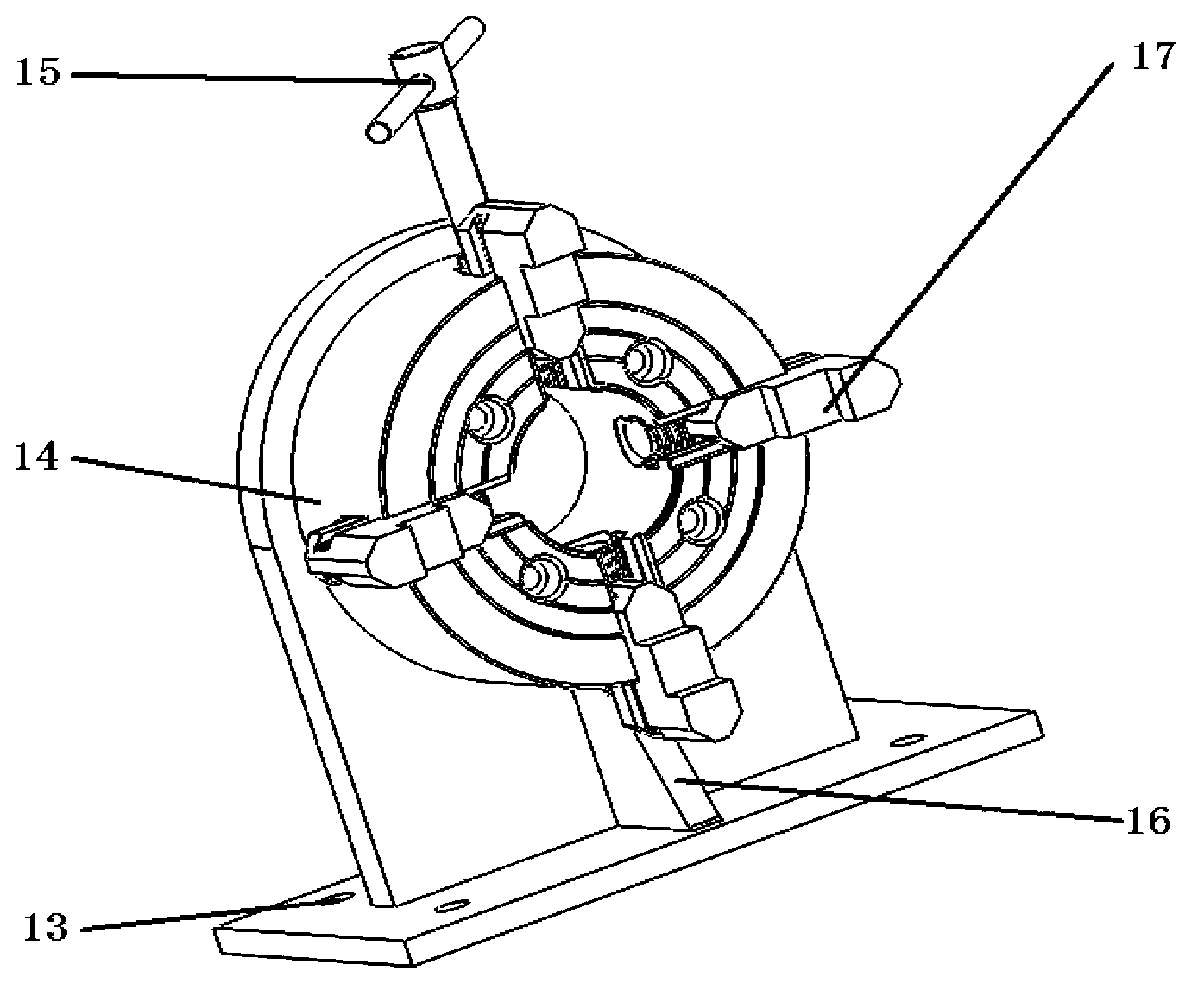

[0031] Such as figure 2 As shown, the clamping mechanism includes a four-jaw chuck and a rotary handle 15 . The four-jaw chuck is a commonly used chuck and mainly includes a chuck body 14, a chuck through hole 13, a reinforcing rib 16 and jaws 17. When the rotary handle 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com