Welding wire filling method for laser welding to narrow gap of Al-alloy

A technology of laser welding and filler wire, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of difficulty in ensuring the stability of the welding process, the influence of the stability of wire feeding and gas feeding, and the difficulty of floating and precipitation of bubbles, etc., to achieve Improved stability and protective effect, reduced chance of porosity, and refined crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are examples of the present invention and comparison of effects.

[0031] Experiment using CO 2 The laser parameters are: wavelength 10.6 μm, power 3500W.

[0032] The aluminum alloy material used in the experiment is: 2219, plate thickness: 20mm.

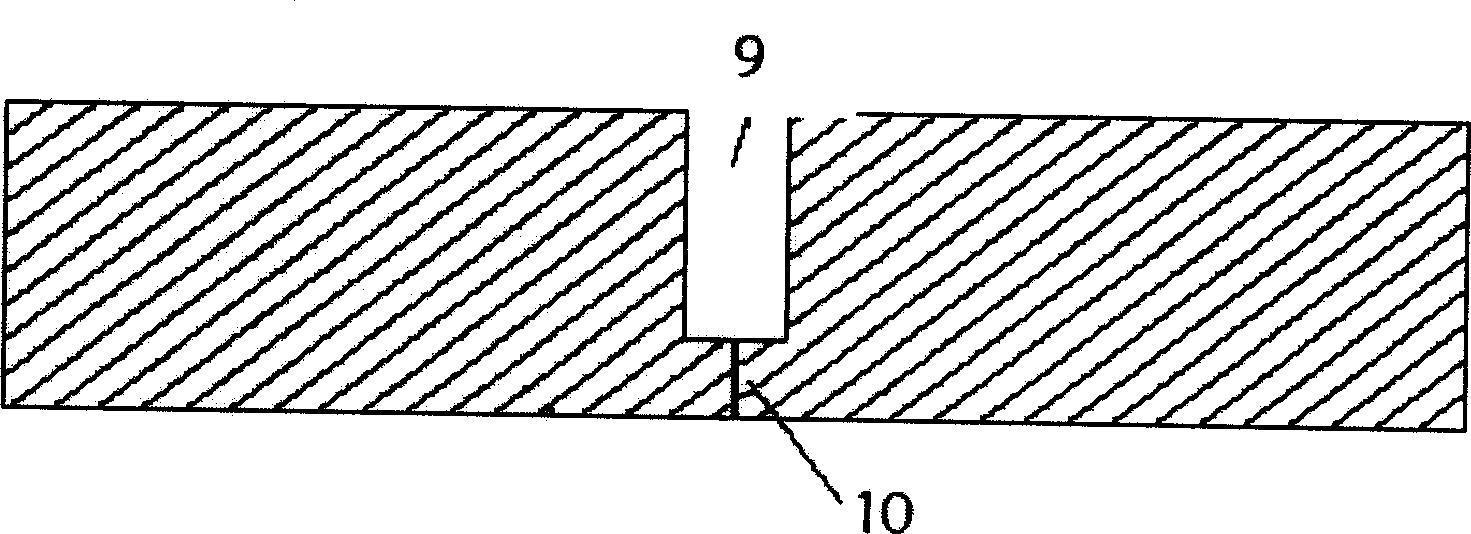

[0033] Narrow gap form: double-sided symmetrical U-shaped bevel with stud edge, stud edge size: 4mm, U-shaped bevel size: 3mm.

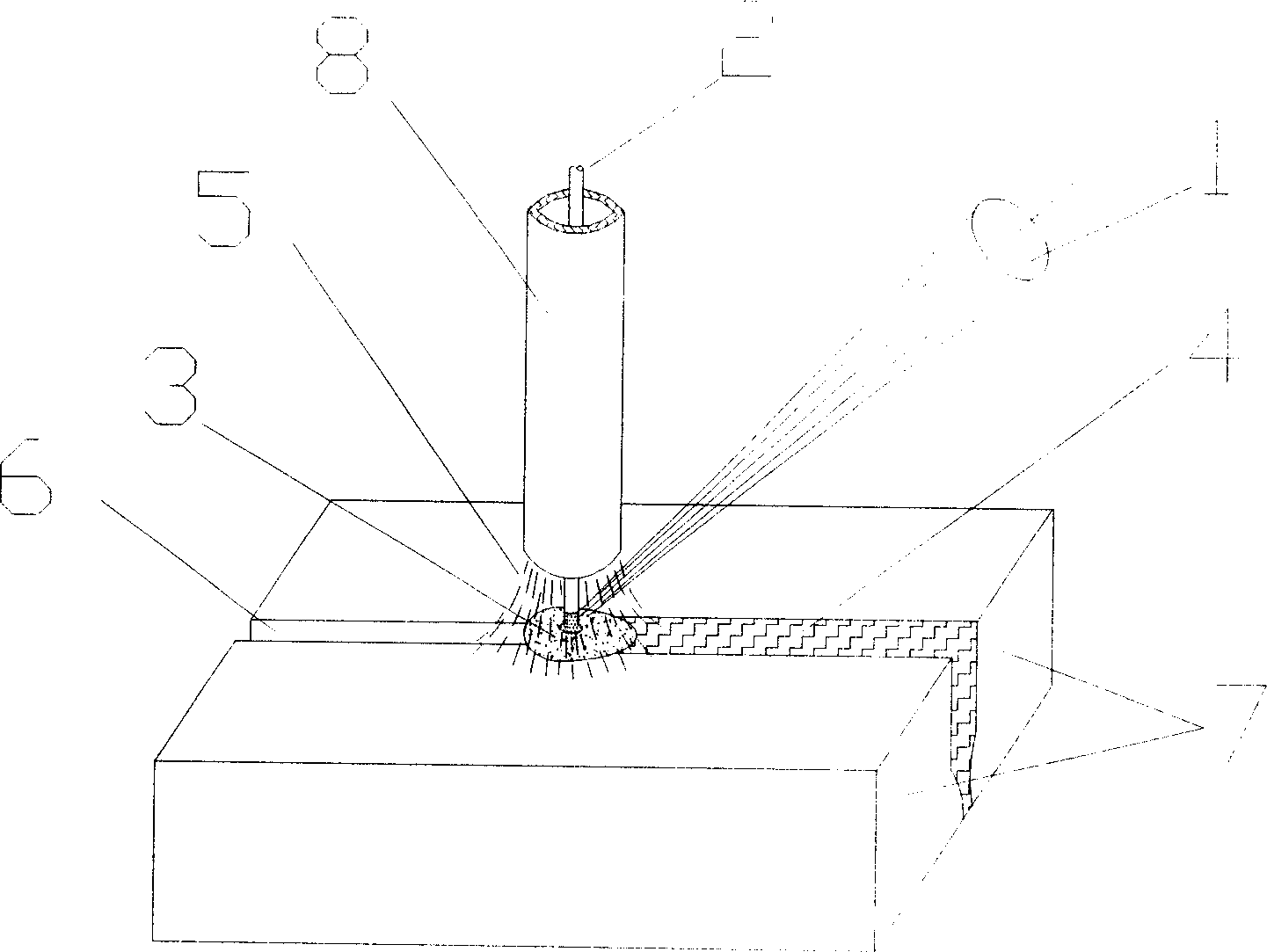

[0034] Laser incidence angle: 30°, the welding wire and shielding gas are coaxially fed into the narrow gap perpendicular to the workpiece surface.

[0035] image 3 and Figure 6 for CO 2 Laser Welding Aluminum Alloy 2219, CO 2 The laser parameters are the above conditions, under the conditions of a narrow gap reserved for the workpiece, welding speed, wire feeding speed and shielding gas flow rate, the commonly used laser is vertically incident, and the welding wire and shielding gas are input at a 45° angle to the surface of the workpiece. The welding method and Comparison o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com