Method and system of three-dimensional weld seam tracking based on visual and rotary electric arc composite sensing

A rotating arc and composite sensing technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as low tracking accuracy, low stability, and susceptibility to interference, and achieve enhanced weld stability and improved The effect of anti-interference ability and tracking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further explained and described below in conjunction with the accompanying drawings and specific embodiments of the description. For the step numbers in the embodiment of the present invention, it is only set for the convenience of explanation and description, and there is no limitation on the order of the steps. The execution order of each step in the embodiment can be carried out according to the understanding of those skilled in the art Adaptive adjustment.

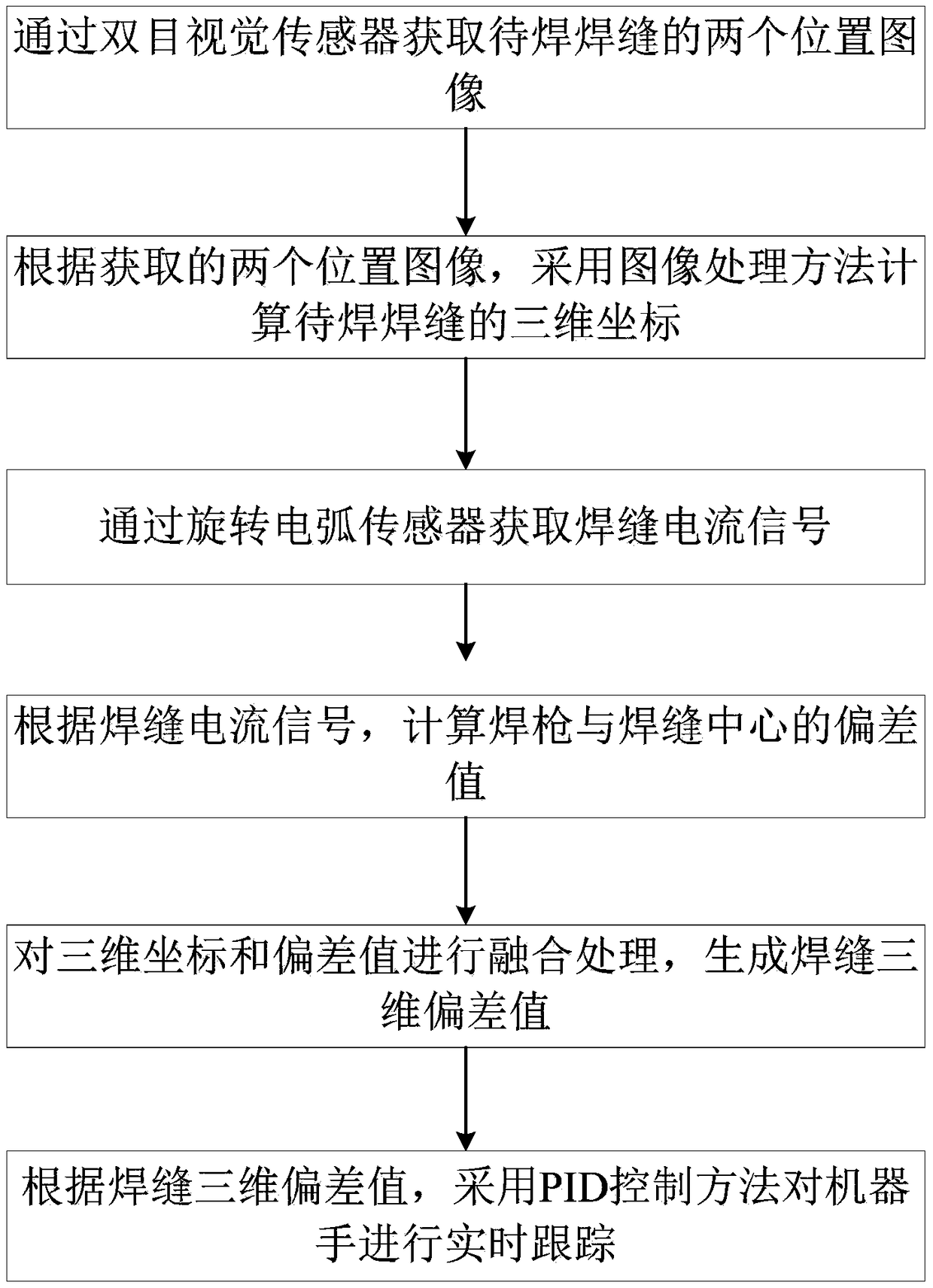

[0055] refer to figure 1 , the present invention is based on the three-dimensional seam tracking method of visual and rotating arc composite sensing, comprising the following steps:

[0056] Obtain two position images of the weld to be welded through the binocular vision sensor;

[0057] According to the acquired two position images, the image processing method is used to calculate the three-dimensional coordinates of the weld to be welded;

[0058] Obtain the weld seam current s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com