Installation method for energy-saving fin keel of ship

An installation method and technology of fins, which are applied to ship parts, ship construction, transportation and packaging, etc., can solve the problems of low installation accuracy, long installation period of energy-saving fins, and poor ship energy-saving effect, so as to improve installation accuracy and ensure The effect of installation accuracy and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below we will further elaborate on the installation method of the energy-saving fins of the present invention in combination with the accompanying drawings and specific examples, in order to understand its operation flow and implementation process more clearly, but this cannot limit the protection scope of the patent of the present invention .

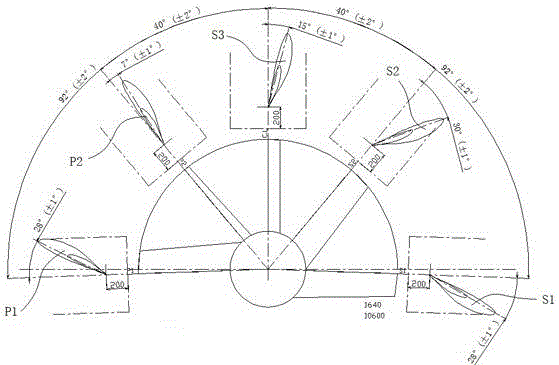

[0031] as attached figure 1 As shown, the energy-saving fin is a pre-vortex device composed of 5 fins, which are respectively recorded as P1, P2, S3, S2, and S1. The 5 fins not only have angles in the circumferential direction, but each The axis angles also vary.

[0032] In an embodiment, the method of the present invention mainly includes the following detailed steps:

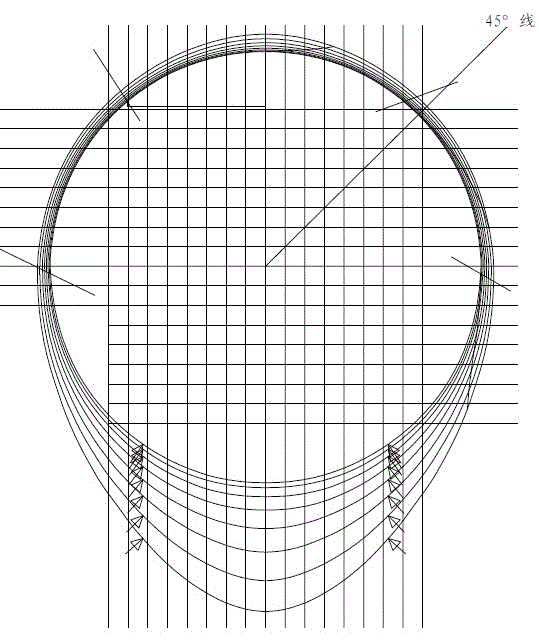

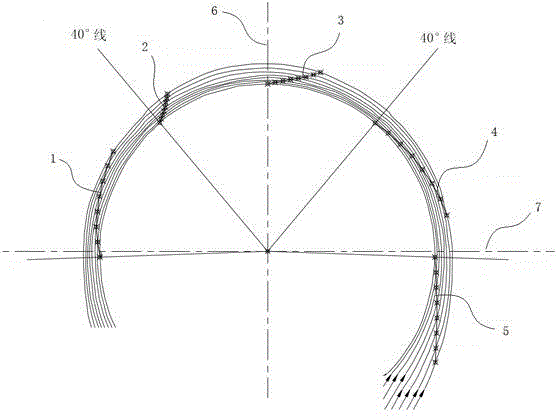

[0033] The first step is the actual measurement of the outline of the outer plate of the stern hub: as attached figure 2 As shown, draw a 45° line according to the theoretical line shape characteristics of the outer plate of the stern hub, draw a longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com