Device and method for welding antenna connector to automotive glass

A technology for automotive glass and antennas, applied in auxiliary devices, welding equipment, manufacturing tools, etc., can solve problems such as unsuitable antenna joints, unstable welding quality, and affecting product appearance, so as to improve welding strength and welding stability, and ensure Appearance, effects with a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The content of the present invention will be further described below in conjunction with the accompanying drawings.

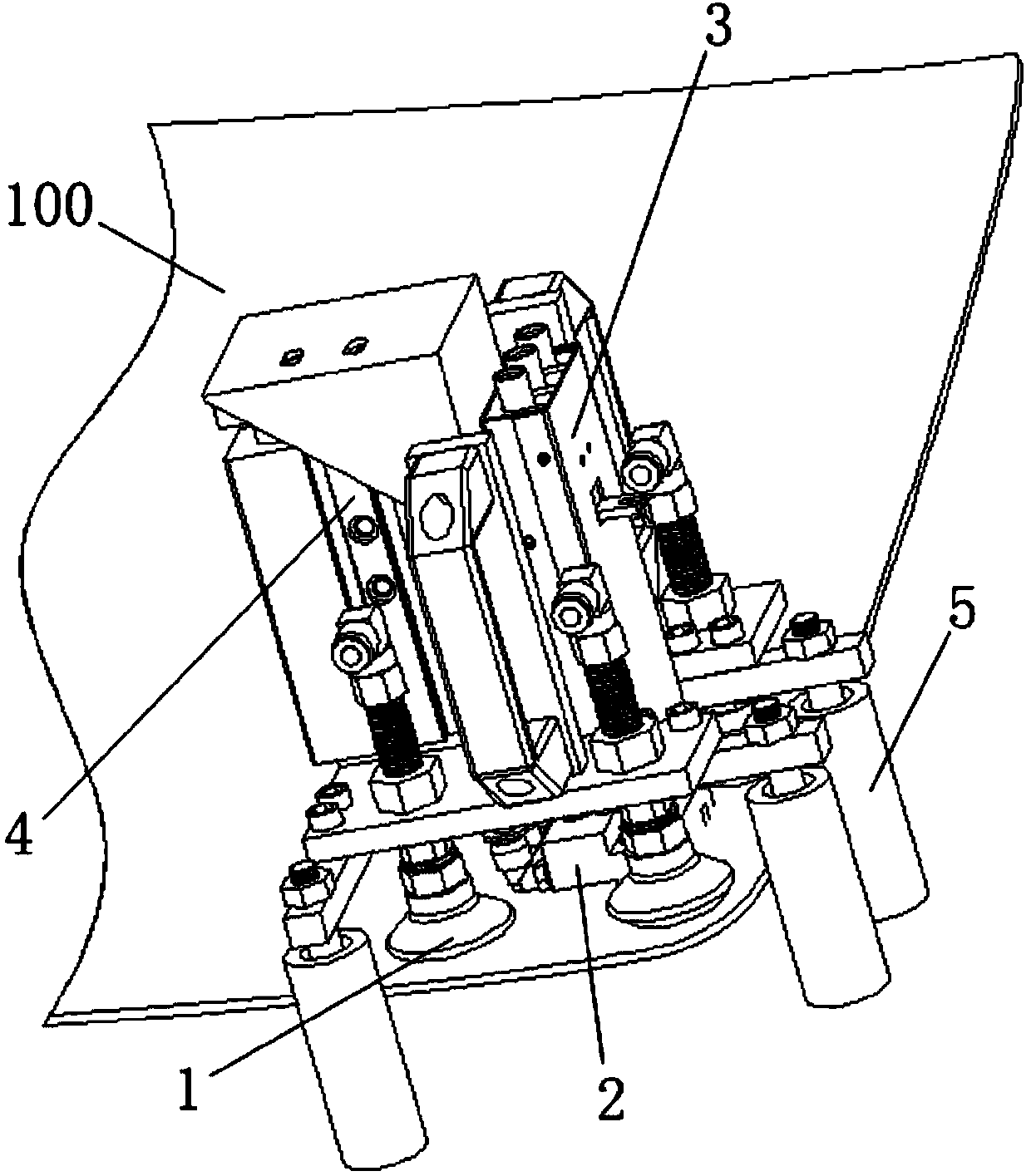

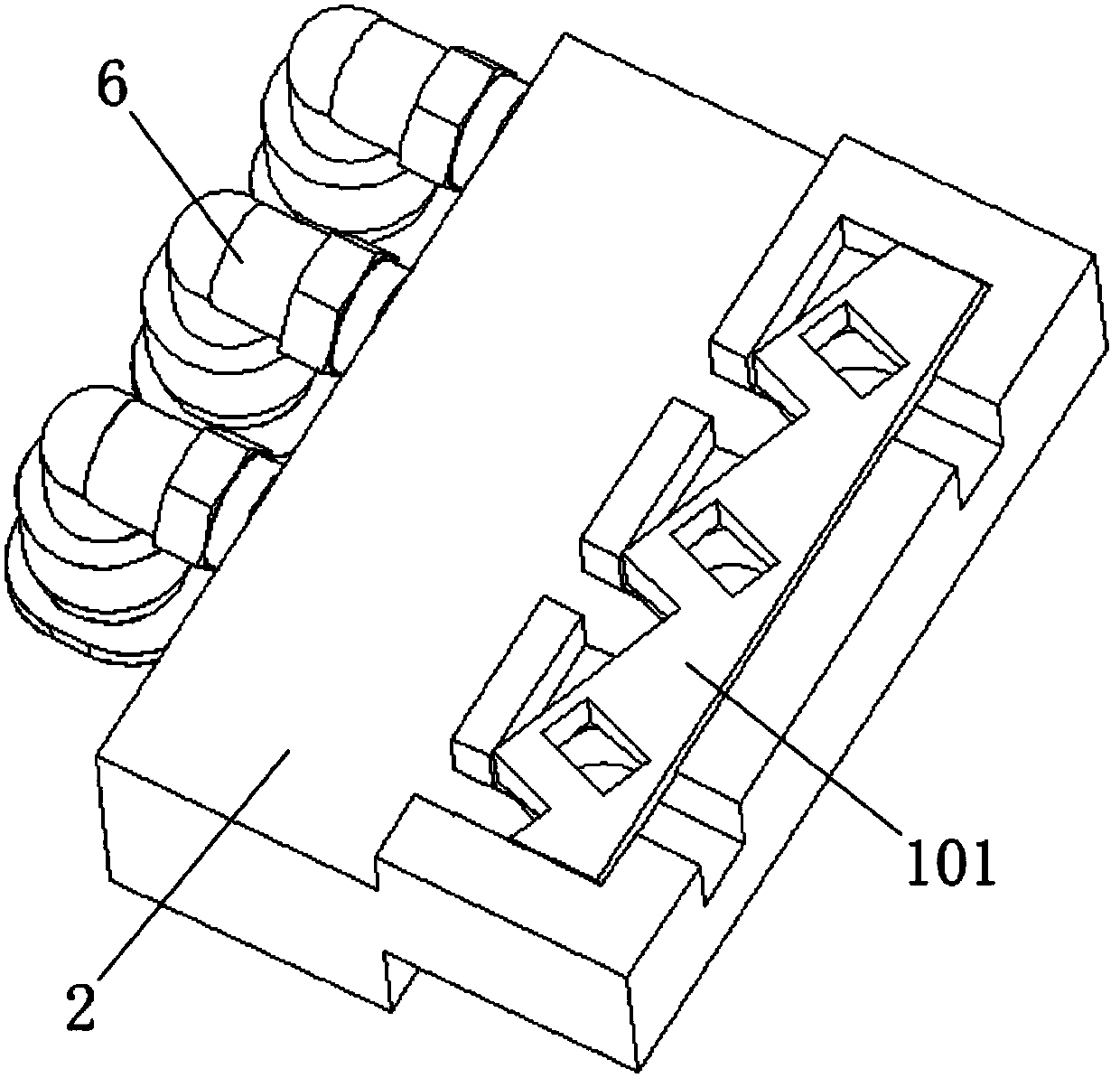

[0029] Such as figure 1 As shown, the device for welding the antenna joint to the automobile glass 100 according to the present invention includes a welding positioning mechanism 1, an accessory fixing mechanism 2, a welding mechanism 3 and a driving mechanism 4, and the welding positioning mechanism 1 is used to position the welding mechanism when welding. 3 is positioned and fixed relative to the automobile glass 100, the accessory fixing mechanism 2 is used to place the antenna joint to be welded, the welding mechanism 3 is used to weld the antenna joint to the automobile glass 100, and the driving mechanism 4 is used to drive the welding mechanism 3 for welding.

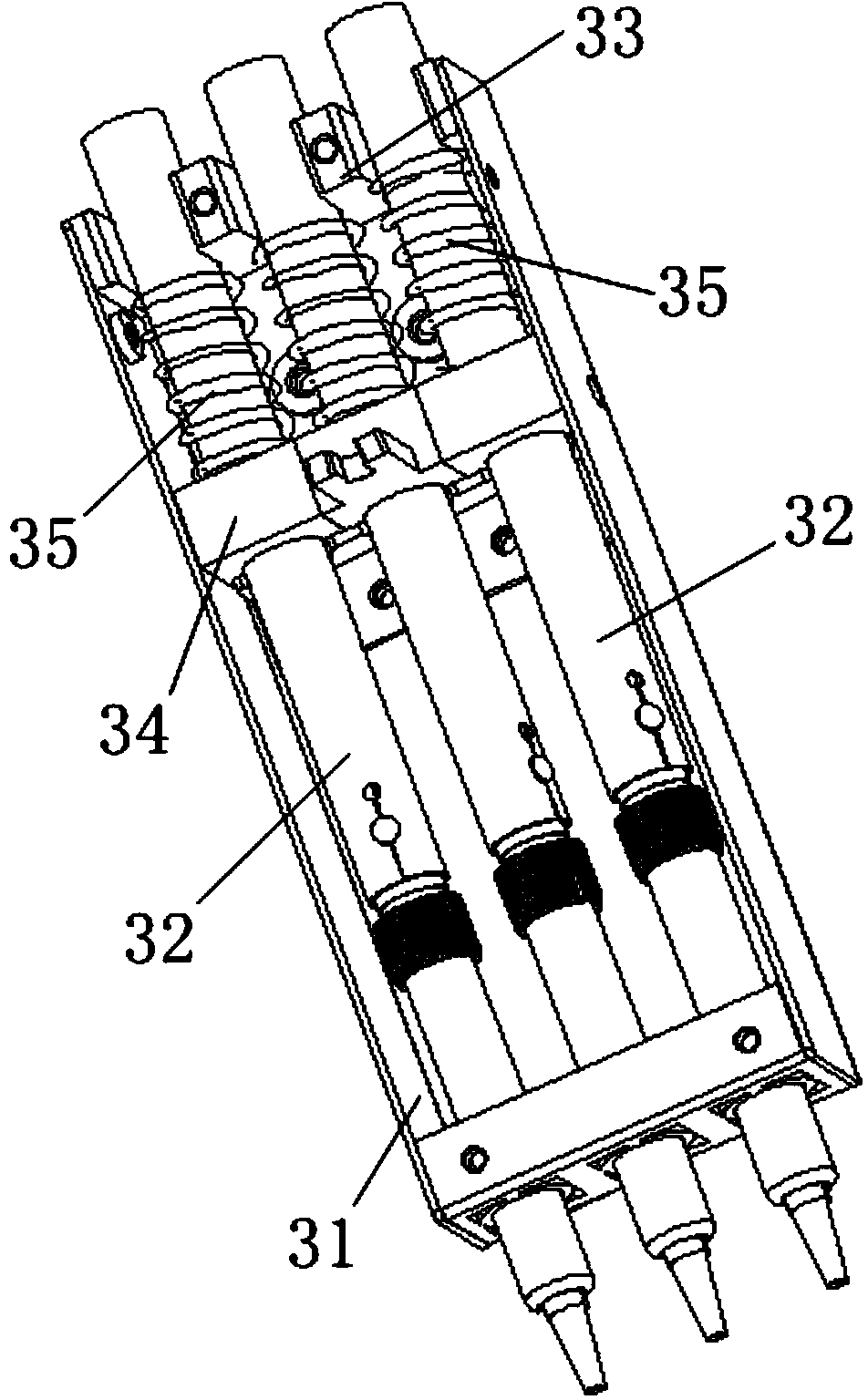

[0030] Such as figure 2 As shown, the welding mechanism 3 includes a base 31, at least two electric soldering irons 32, a guide device 33 and a fixing seat 34, the middle part of the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com