Skew offset pipe trajectory planning method based on arc welding robot system

A robot system and offset tube technology, applied in arc welding equipment, manipulators, welding equipment, etc., can solve the problems of difficulty in guaranteeing welding quality and efficiency, high welding strength, and easy occurrence of singular points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

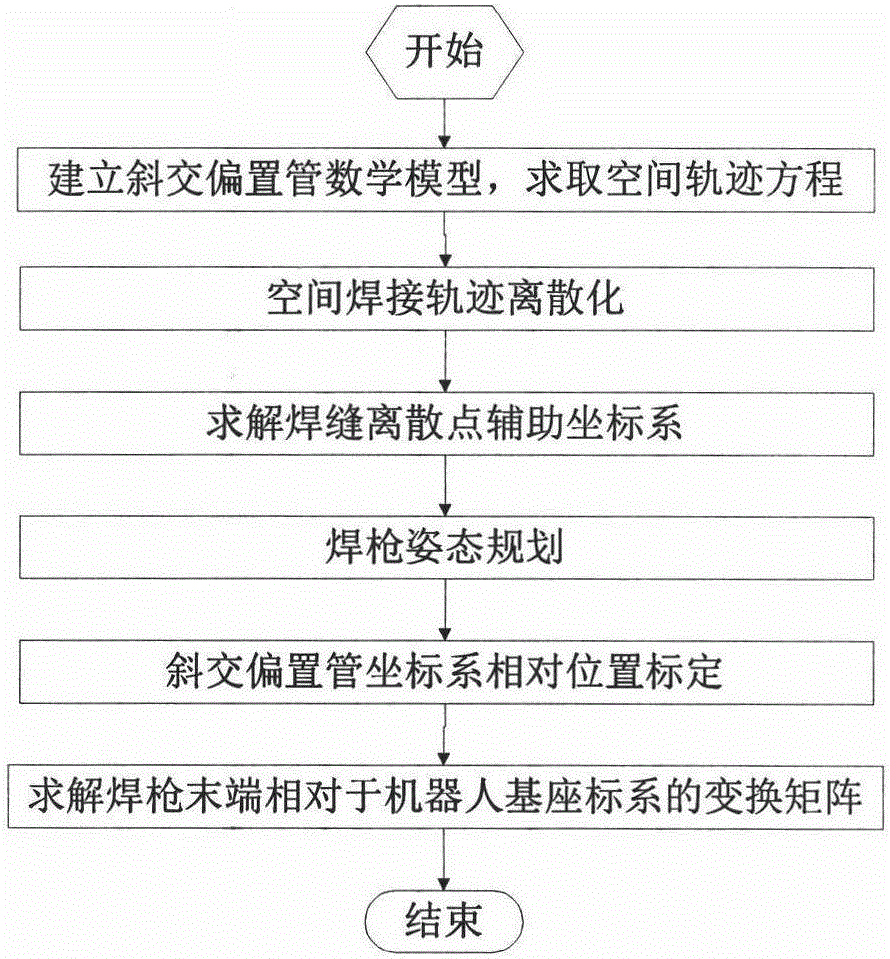

[0028] Such as figure 1 Shown is the flow chart of trajectory planning for arc welding robot system welding oblique offset pipe, and the implementation of the present invention will be further described below according to the accompanying drawings and specific examples:

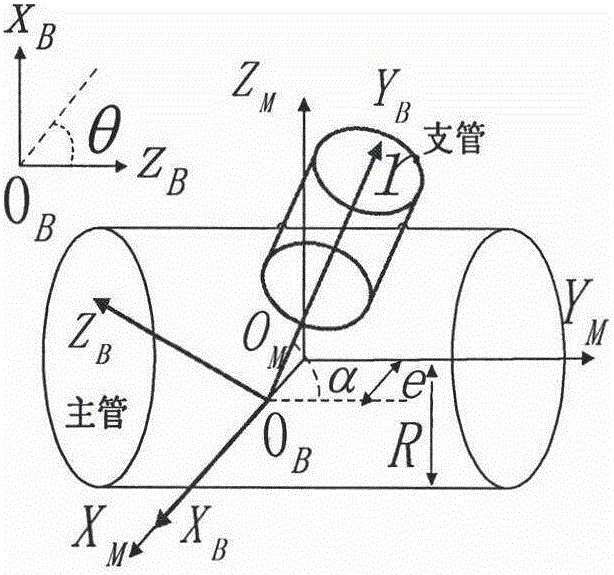

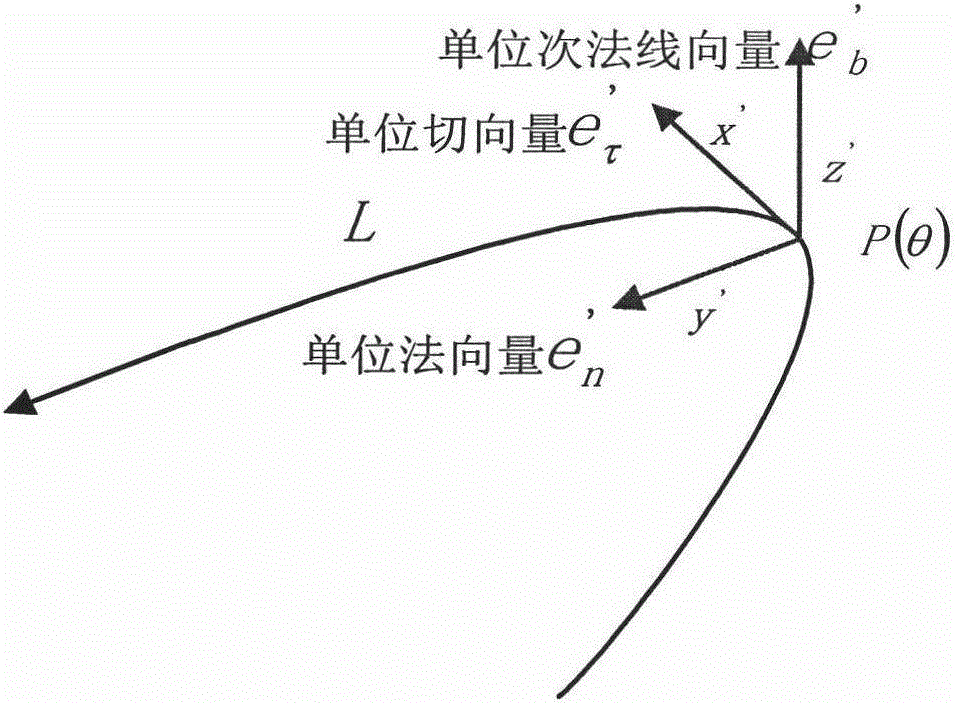

[0029] Establish oblique offset tube workpiece coordinate system, solve the space intersecting curve equation; establish the corresponding space intersecting curve weld discrete point expression; construct the welding discrete point auxiliary coordinate system relative to the oblique offset tube workpiece coordinate system transformation matrix; construct the transformation matrix between the welding torch coordinate system and the weld discrete point auxiliary coordinate system; through a special teaching method, construct the homogeneous transformation of the oblique offset tube workpiece coordinate system relative to the robot workpiece coordinate system matrix; solve the pose matrix of the welding torch o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com