Automatic welding tractor

An automatic welding and trolley technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of simple structure and portability, and achieve the effects of light weight, strong versatility and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

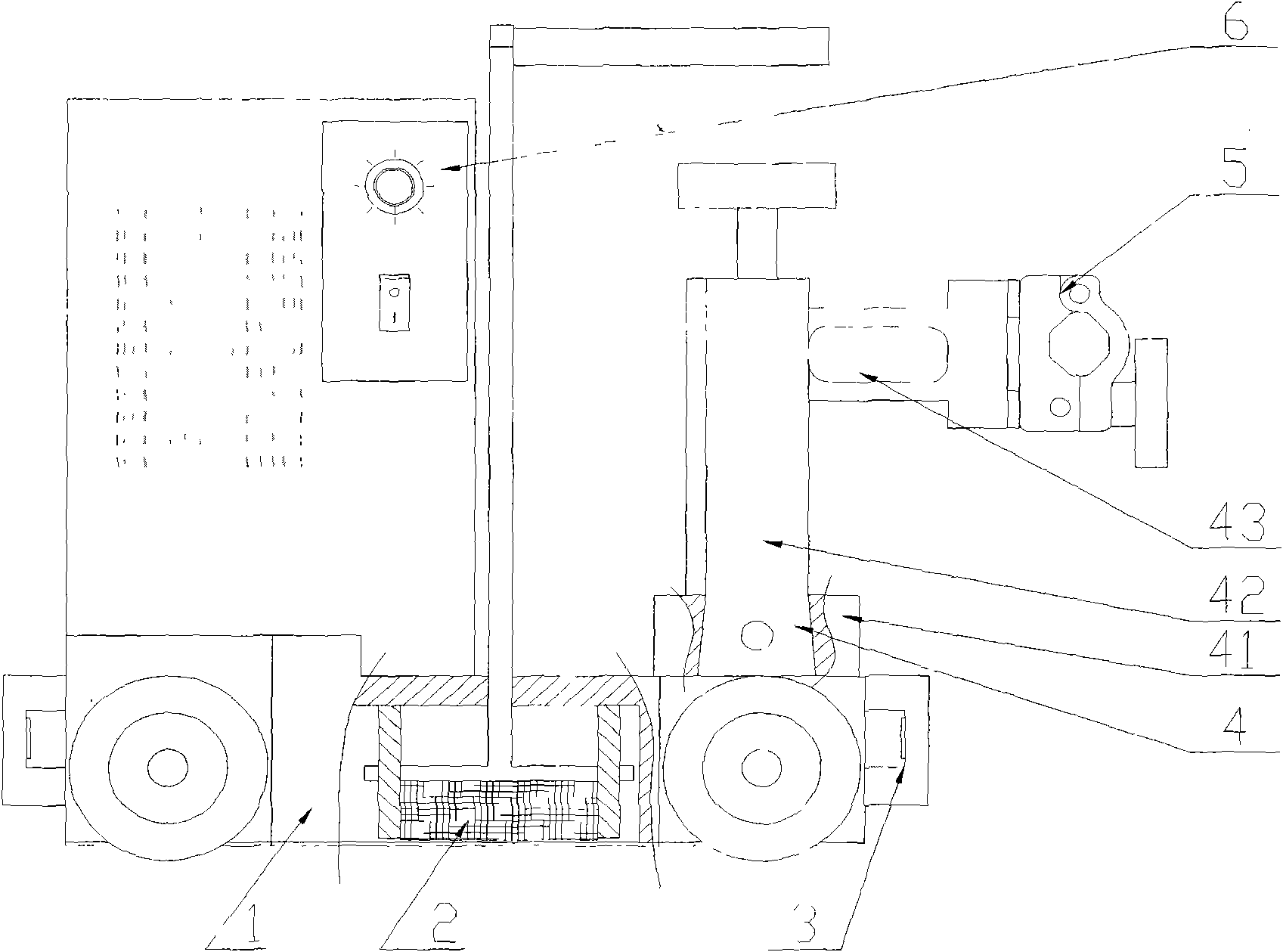

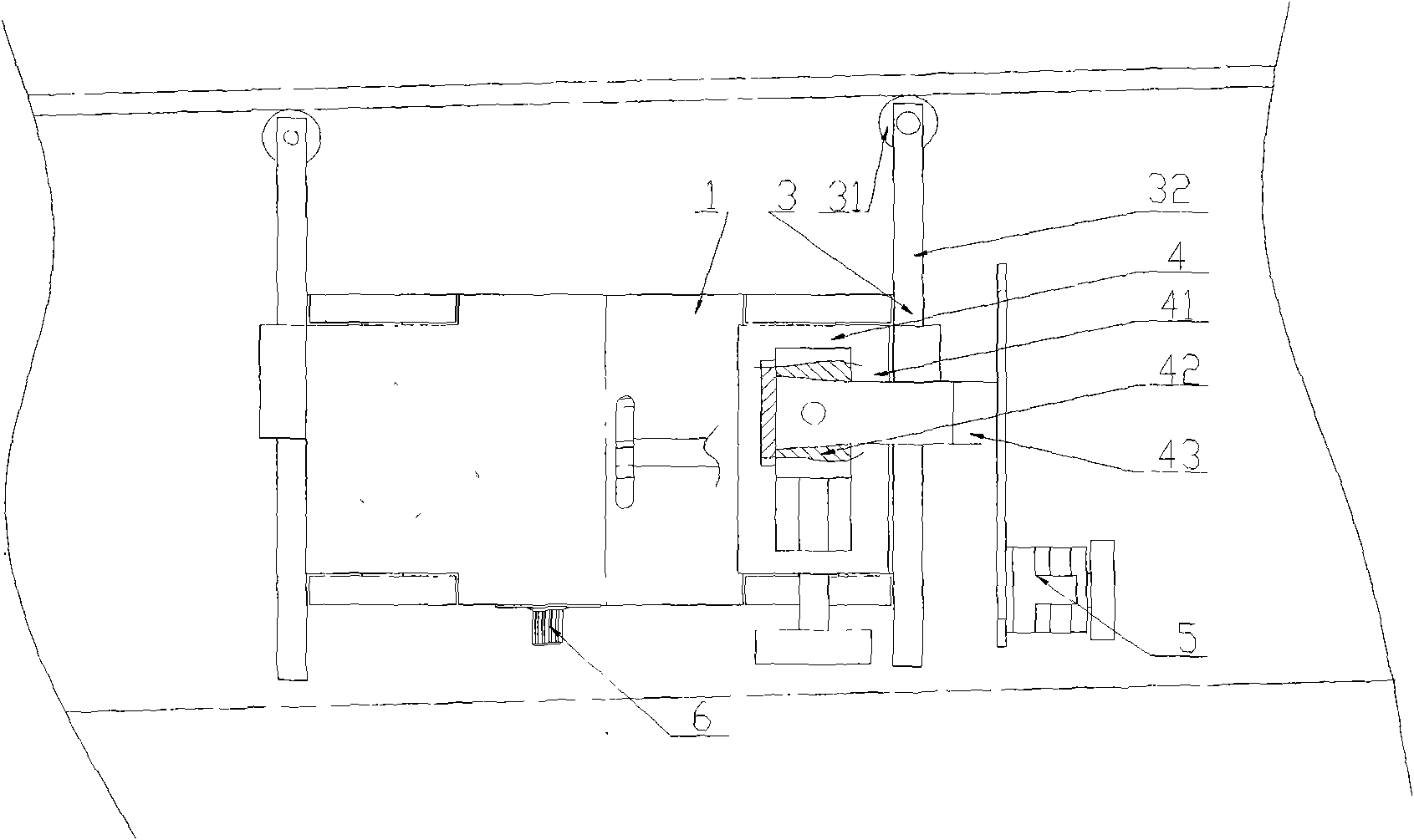

[0010] attached figure 1 , 2 A schematic diagram showing the preferred embodiment of the present invention.

[0011] Attached below figure 1 , 2 Further describe the detailed technical content and the best embodiment of the present invention.

[0012] The present invention provides a kind of automatic welding trolley, comprises a car body / body 1 and four wheels, and welding torch and motor, also comprises, on car body 1, welding torch clamp 5 is housed, and welding torch clamp can clamp welding torch along welding Welding in the seam direction, the inherent permanent magnet powerful magnet 2 is installed on the bottom surface of the car body 1, and the permanent magnet powerful magnet can be attracted to the metal plate preset on the ground to realize fixing the trolley, and a guide mechanism 3 is arranged on the side of the car body 1, The guide mechanism positions the welding torch and the welding seam. The car body 1 is equipped with a manual fine-tuning device 4, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com