Vision sensing-based laser-electric arc hybrid welding real-time automatic control device and welding method thereof

An automatic control device and hybrid welding technology, applied in laser welding equipment, welding equipment, manufacturing tools, etc., can solve the problem that the distance between the droplet and the center of the laser keyhole is too far, the adjustment process cannot be visualized, and the center of the droplet and the laser keyhole The distance cannot be adjusted in real time to achieve the effect of improving stability and avoiding reflective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

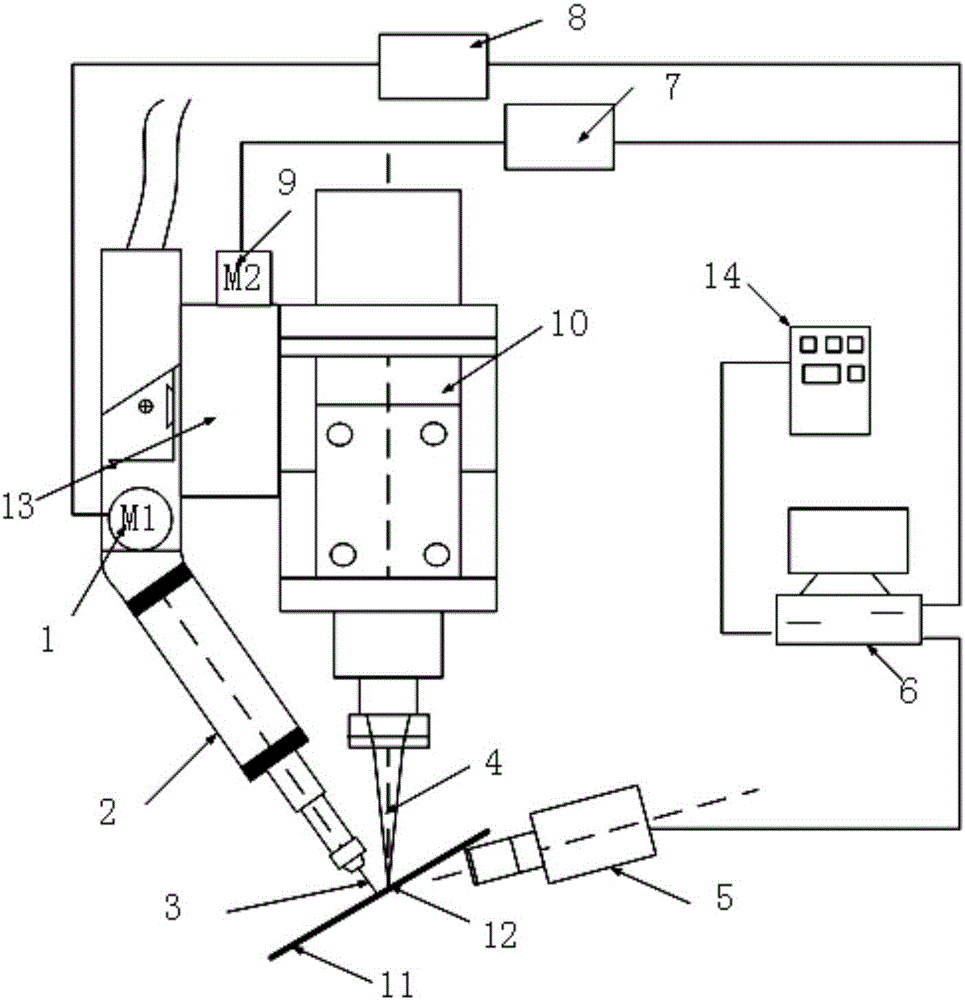

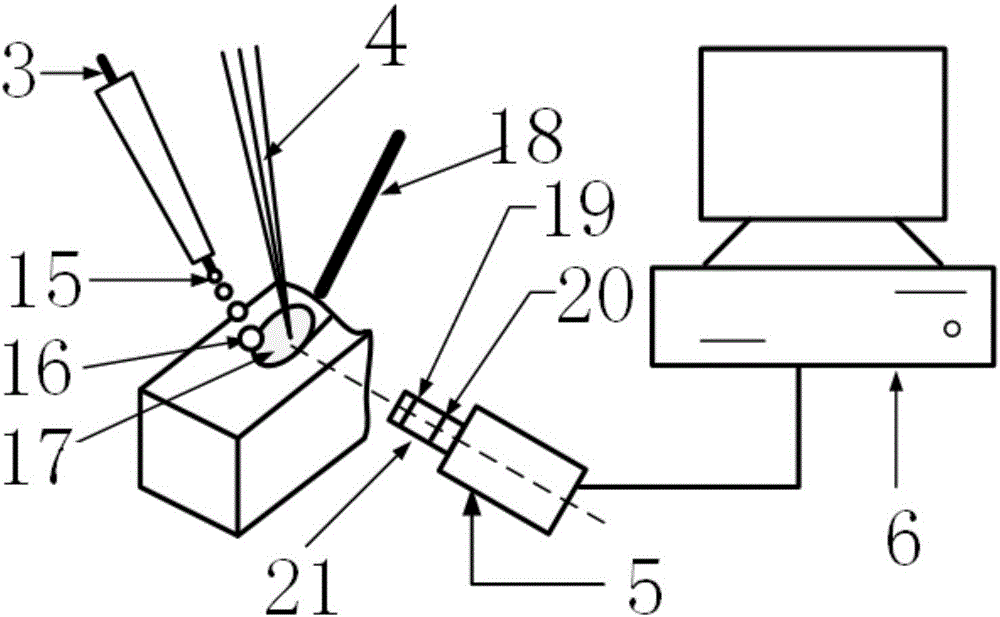

[0049] Adopt the welding method of laser-arc hybrid welding real-time automatic control device of the present invention, as Figure 4-5 As shown, follow the steps below:

[0050] Step 1: Before welding, clamp the weldment 11 with a thickness of 8.0mm on the workbench. The laser adopts Nd:YAG solid-state laser from Trumpf, Germany. The laser is focused by a 220mm focusing lens to obtain a 0.5mm diameter spot; defocus The power of the Nd:YAG solid-state laser is 2.0KW; the welding torch 2 uses a Panasonic YD-350AG2HGE MIG welding torch with a maximum arc current of 350A. The length is 14mm, the relative welding speed of welding torch 2 is 800mm / min, the diameter of welding wire of welding torch 2 is Φ1.2mm, and the shielding gas of welding torch 2 is CO with a volume ratio of 5%. 2 The %Ar of +95, the gas flow rate is 15L / min; Set the parameter of high-speed camera 5, under the condition that does not have optical filter 19, the aperture 20 of lens 21 is adjusted to 4, exposure...

Embodiment 2

[0056] Adopt the welding method of laser-arc hybrid welding real-time automatic control device of the present invention, as Figure 4-5 As shown, follow the steps below:

[0057] Step 1: Before welding, clamp the weldment 11 with a thickness of 8.0mm on the workbench, and the laser uses CO 2 Laser with a power of 2.0KW; Welding torch 2 adopts Panasonic YD-350AG2HGE MAG welding torch with a maximum arc current of 350A, adjust the arc welding current of welding torch 2 to 200A, arc voltage to 27V, dry elongation of welding wire to 14mm, and the relative welding speed of welding torch 2 800mm / min, the welding wire diameter of welding torch 2 is Φ1.2mm, and the shielding gas of welding torch 2 is CO with a volume ratio of 5%. 2 The %Ar of +95, the gas flow rate is 17L / min; Set the parameter of high-speed camera 5, under the condition that does not have optical filter 19, the aperture 20 of lens 21 is adjusted to 6, exposure time is adjusted to 1 / 50, sampling frequency Adjust to ...

Embodiment 3

[0063] Adopt the welding method of laser-arc hybrid welding real-time automatic control device of the present invention, as Figure 4-5 As shown, follow the steps below:

[0064] Step 1: Before welding, clamp the weldment 11 with a thickness of 8.0mm on the workbench, and the laser uses CO 2 Laser with a power of 2.0KW; welding torch 2 adopts Panasonic YD-350AG2HGE MAG welding torch with a maximum arc current of 350A, adjust the arc welding current of welding torch 2 to 200A, arc voltage to 26V, dry elongation of welding wire to 14mm, and the relative welding speed of welding torch 2 800mm / min, the welding wire diameter of welding torch 2 is Φ1.2mm, and the shielding gas of welding torch 2 is CO with a volume ratio of 5%. 2 The %Ar of +95, the gas flow rate is 16L / min; Set the parameter of high-speed camera 5, under the condition without filter 19, the aperture 20 of lens 21 is adjusted to 6, exposure time is adjusted to 1 / 50s, sampling frequency Adjust to 50 frames per seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com