Laser-assisted fuse hollow tungsten electrode argon arc coaxial wire filling welding method

A laser-assisted, argon tungsten arc technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low welding deposition efficiency and low welding wire melting speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

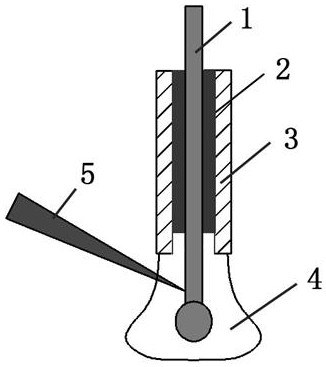

[0024] A laser-assisted fuse hollow tungsten argon arc coaxial filler wire welding method, the method includes: preparing welding wire 1, insulating layer 2 and hollow tungsten electrode 3, step 1: before welding, grinding or cleaning the workpiece to be welded, and Fix the workpiece to be welded after grinding or cleaning, use low-alloy steel as the surfacing base material, the size is 30mm×150mm×300mm, and the nickel-based alloy ERNiCrFe-7 is used as the filler wire, and the diameter of the wire is 1.2 mm. The outer diameter of the hollow tungsten electrode is 6 mm, the inner diameter is 3 mm, and the ceramic tube is fixed in the inner hole of the tungsten electrode as the insulating layer for the welding wire and the inner wall of the hollow tungsten electrode. The outer diameter of the ceramic tube is 3 mm, and the inner diameter is 1.5 mm. , grinding or cleaning the base metal of low alloy steel, and fixing it after grinding;

[0025] An insulating layer is fixed in the i...

Embodiment 2

[0031] According to the laser-assisted fuse hollow tungsten argon arc coaxial filler wire welding method described in embodiment 1, the diameter of the welding wire is not greater than the central hole of the hollow tungsten pole, and when the welding wire is fed through the central hole of the hollow tungsten pole, the welding wire and the tungsten pole The inner walls are kept insulated by insulating layers.

Embodiment 3

[0033] According to the laser-assisted fuse hollow tungsten argon arc coaxial wire-filled welding method described in embodiment 1, the welding heating method of the molten pool is hollow tungsten arc heating, the laser heat source acts on the welding wire, and the laser acts on the welding wire The point is in the area of the hollow tungsten arc, and the combined heating of the laser and the hollow tungsten arc increases the melting speed of the welding wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com