A Surfacing Welding Method for Stainless Steel Castings with Controlled Depth of Penetration

A surface surfacing and stainless steel technology, which is applied in the field of surfacing welding, can solve the problems of difficulty in surfacing welding and lack of fusion on the surface of the pipe, and achieve the effects of fast welding speed, reduction of non-fusion and reduction of dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

[0032] A method for surface overlay welding of stainless steel castings with controlled penetration, the method comprising the steps of:

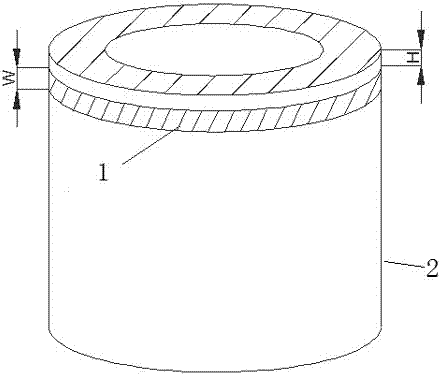

[0033] S1, spot welding extension rings on the outer wall and inner wall of the connecting pipe respectively;

[0034] S2, 100% penetration testing at the weld of the extension ring;

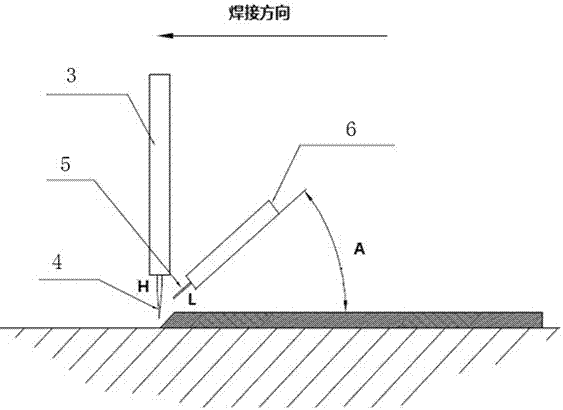

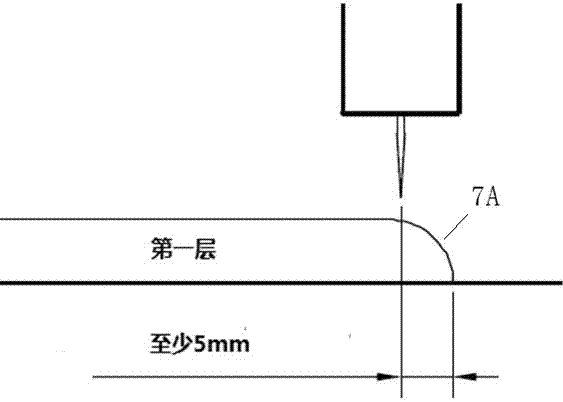

[0035] S3, the hot wire tungsten argon arc automatic welding method with argon protection is used to form a surfacing layer after several layers of surfacing welding on the butt pipe, and the current polarity adopts DC reverse connection. Use a certain range of current, voltage, welding speed and wire feeding speed during surfacing;

[0036] S4, after the surfacing is completed, the surfacing layer is ground, and the extension rings on the outer diameter side and the inner diameter side of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com