Laser welding method, connection method of electrode post and cover plate and cover plate

A laser welding and electrode technology, applied in laser welding equipment, battery cover/end cover, welding equipment, etc., can solve the problems of high processing cost, achieve low processing cost, ensure air tightness and safety, and improve welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

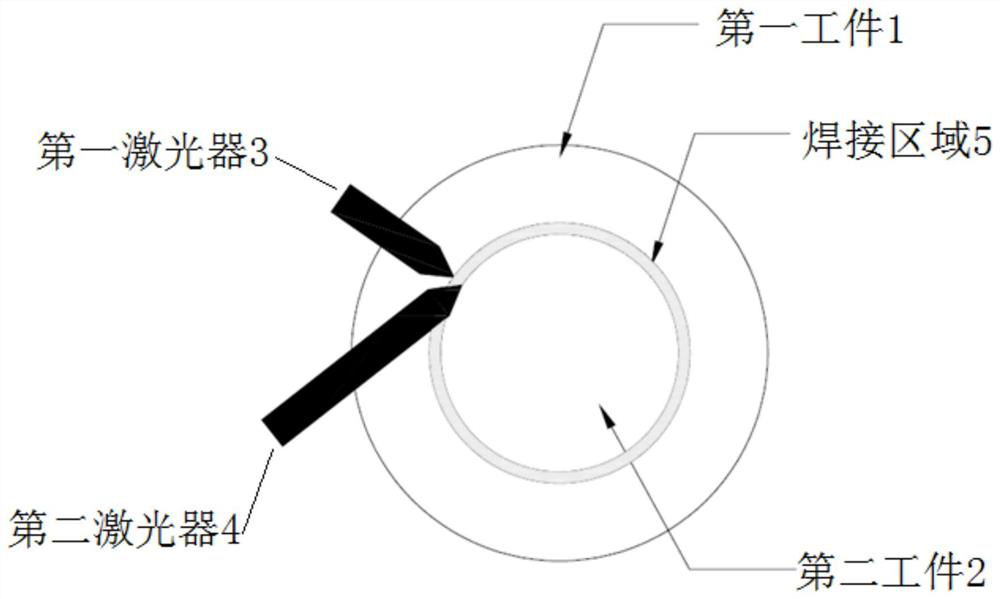

[0029] figure 1 A schematic diagram of a welding principle of a laser welding method according to an embodiment of the present invention is shown.

[0030] Such as figure 1 As shown, a laser welding method is used to weld the preset welding area 5 of the riveted structure. The riveted structure includes riveted first workpiece 1 and second workpiece 2. The method includes:

[0031] The first laser 3 is welded along the first workpiece 1 side of the welding area 5, and the second laser 4 is used for welding along the second workpiece 2 side of the welding area 5. During the welding process, the first laser 3 and the second laser 4 Maintain synchronous action, and the first laser 3 and the second laser 4 act on both sides of the same position of the welding area 5 at the same time;

[0032] Wherein, the welding power of the first laser 3 matches the melting point of the first workpiece 1 , and the welding power of the second laser 4 matches the melting point of the second work...

Embodiment 2

[0038] The embodiment of the present invention also proposes a method for connecting the electrode pole of the lithium battery and the cover plate, the cover plate includes a through hole, and the method includes:

[0039] Rivet the electrode pole into the through hole of the cover plate;

[0040] The laser welding method as in Example 1 is used to weld and reinforce the riveted joint between the electrode pole and the through hole, wherein the cover plate is the first workpiece 1 and the electrode pole is the second workpiece 2 .

[0041] Specifically, the electrode post is fixed in the through hole of the cover plate by first riveting and then welding, which can effectively ensure the airtightness and safety of the top cover plate. For example, the positive pole and the cover plate are made of aluminum, and the negative pole is made of copper. When welding the positive pole and the cover plate, two lasers with the same power can be used for simultaneous welding. When the bo...

Embodiment 3

[0043] The embodiment of the present invention also proposes a lithium battery top cover, including a cover plate and an electrode pole, and the electrode pole and the cover plate are fixed together by the connection method of the lithium battery electrode pole and the cover plate in the second aspect. The lithium battery top cover has good airtightness and safety.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com