A laser coaxial wire feeding metal parts forming device with variable wire feeding angle

A technology for coaxial wire feeding and metal parts, applied in tin feeding devices, metal processing equipment, metal material coating technology, etc., can solve problems such as many optical problems, insufficient coupling of optical materials, complex optical paths, etc., and achieve laser energy High utilization rate, improved laser utilization rate, high material utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

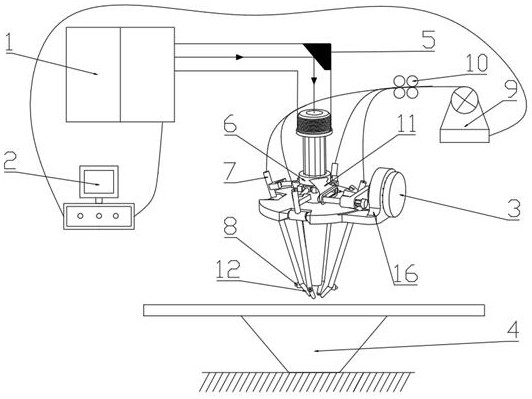

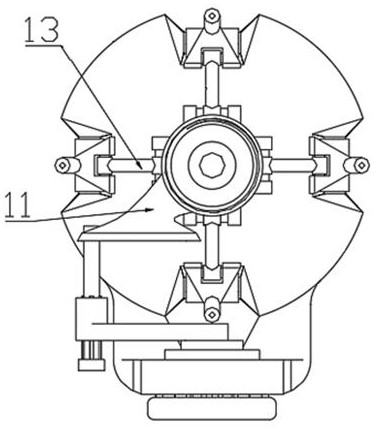

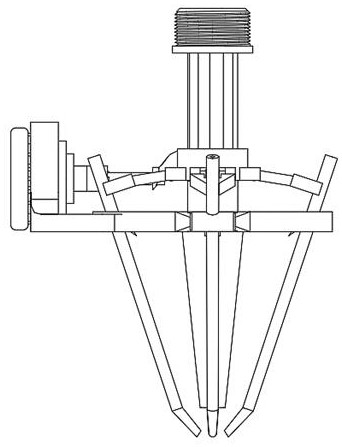

[0037] Embodiment 1: as Figure 1~4 , 6, a laser coaxial wire feeding metal parts forming device with a variable wire feeding angle, including a focusing mirror 5, a laser generator 1, a wire feeding system 9, a shielding gas system 8, and an optical wire control system 2. The wire system 9 includes a wire feeder, a wire feed pipeline 7 and a variable wire feed angle nozzle 12. The wire feeder communicates with the variable wire feed angle nozzle 12 through the wire feed pipeline 7. The laser generator 1 and the wire feed system 9 are respectively connected to the The light filament control system 2 is electrically connected, the laser transmission channel and the laser output channel are all set on the machine tool or multi-axis robot, the focusing mirror 5 is set at the junction of the laser transmission channel and the laser output channel, and the end of the laser output channel is connected to the laser nozzle. The top is fixedly connected, the laser from the laser genera...

Embodiment 2

[0045] Embodiment 2: as Figure 1~6 As shown, a laser coaxial wire feeding metal parts forming device with variable wire feeding angle includes a focusing mirror 5, a laser generator 1, a wire feeding system 9, a shielding gas system 8, an optical wire control system 2, and a wire feeding system 9 includes a wire feeder, a wire feed pipe 7 and a variable wire feed angle nozzle 12. The wire feeder communicates with the variable wire feed angle nozzle 12 through the wire feed pipe 7. The laser generator 1 and the wire feed system 9 are respectively connected to the light wire The control system 2 is electrically connected, the laser transmission channel and the laser output channel are both set on the machine tool or multi-axis robot, the focusing mirror 5 is set at the junction of the laser transmission channel and the laser output channel, and the end of the laser output channel is fixed to the top of the laser nozzle connection, the laser from the laser generator 1 is injecte...

Embodiment 3

[0055] Embodiment 3: as Figure 1~6 As shown, a laser coaxial wire feeding metal parts forming device with variable wire feeding angle includes a focusing mirror 5, a laser generator 1, a wire feeding system 9, a shielding gas system 8, an optical wire control system 2, and a wire feeding system 9 includes a wire feeder, a wire feed pipe 7 and a variable wire feed angle nozzle 12. The wire feeder communicates with the variable wire feed angle nozzle 12 through the wire feed pipe 7. The laser generator 1 and the wire feed system 9 are respectively connected to the light wire The control system 2 is electrically connected, the laser transmission channel and the laser output channel are both set on the machine tool or multi-axis robot, the focusing mirror 5 is set at the junction of the laser transmission channel and the laser output channel, and the end of the laser output channel is fixed to the top of the laser nozzle connection, the laser from the laser generator 1 is injecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com