Process and apparatus for continuous producing double-metal thin plate, thin band by atomized metal ejection

A technology of bimetallic and atomizing nozzles, applied in metal material coating process, fusion spraying, coating, etc., can solve the problems of poor edge quality, insufficient bonding force, and difficult mutual solubility, etc., and achieve compact equipment structure, edge The effect of good internal quality and excellent surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

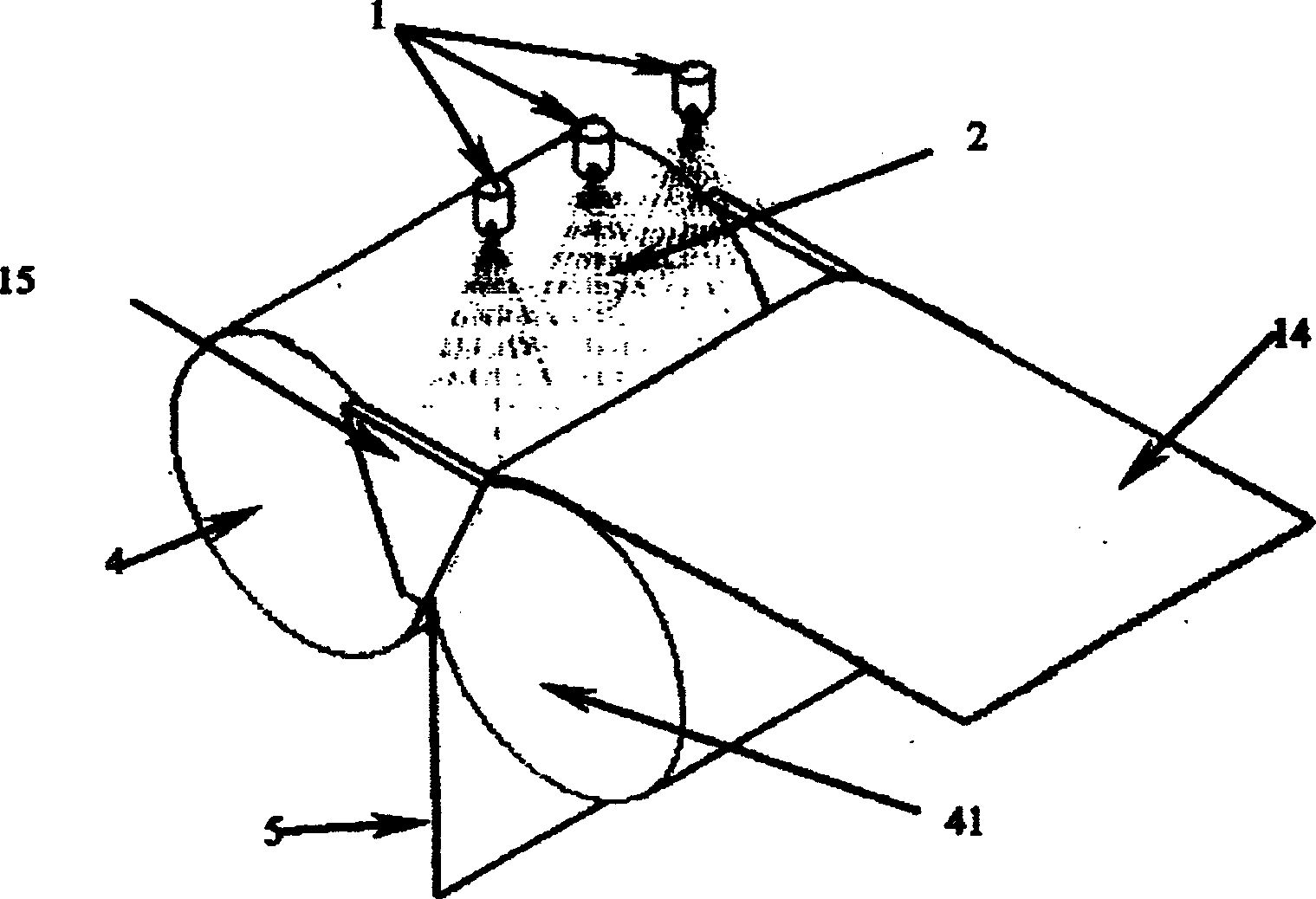

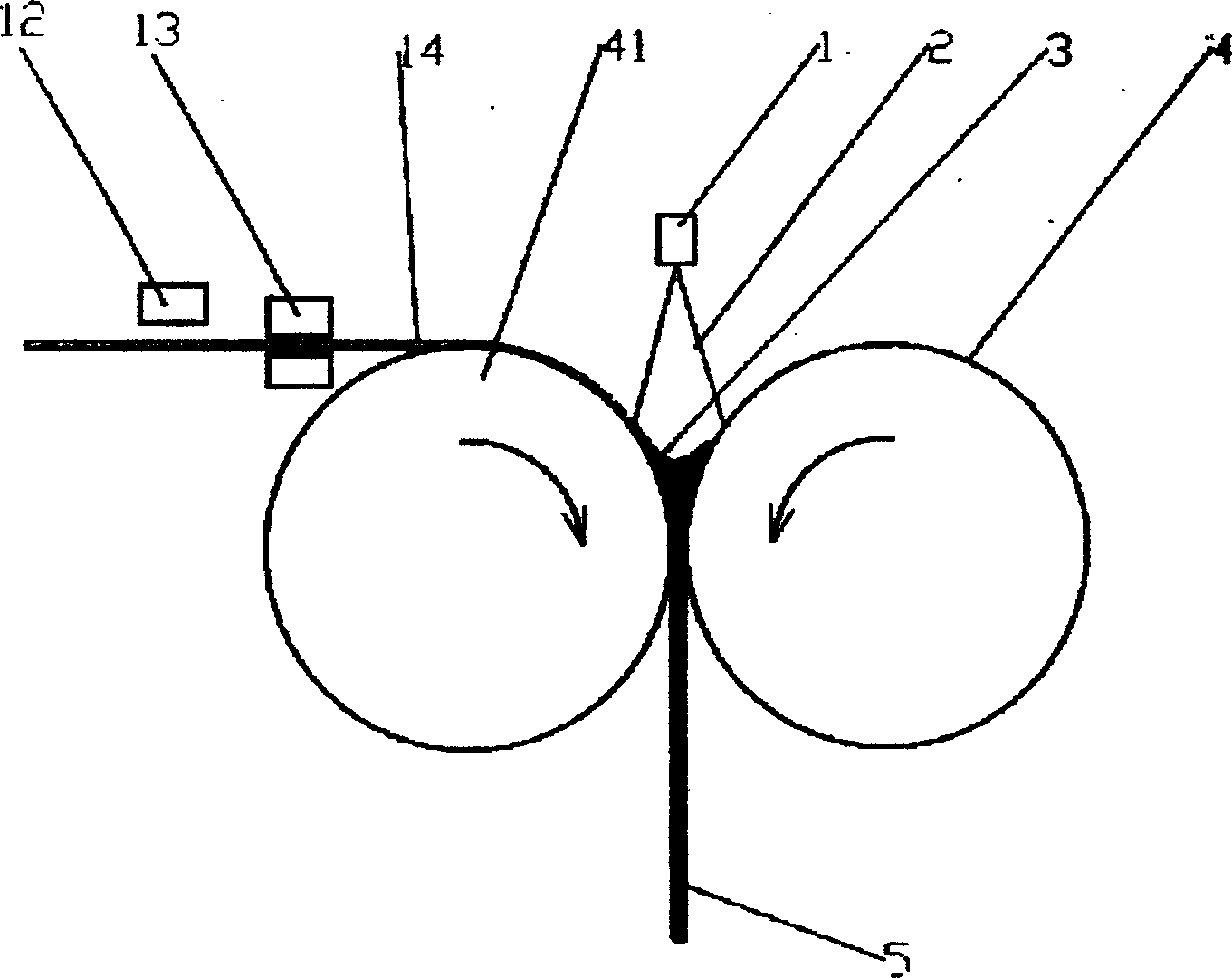

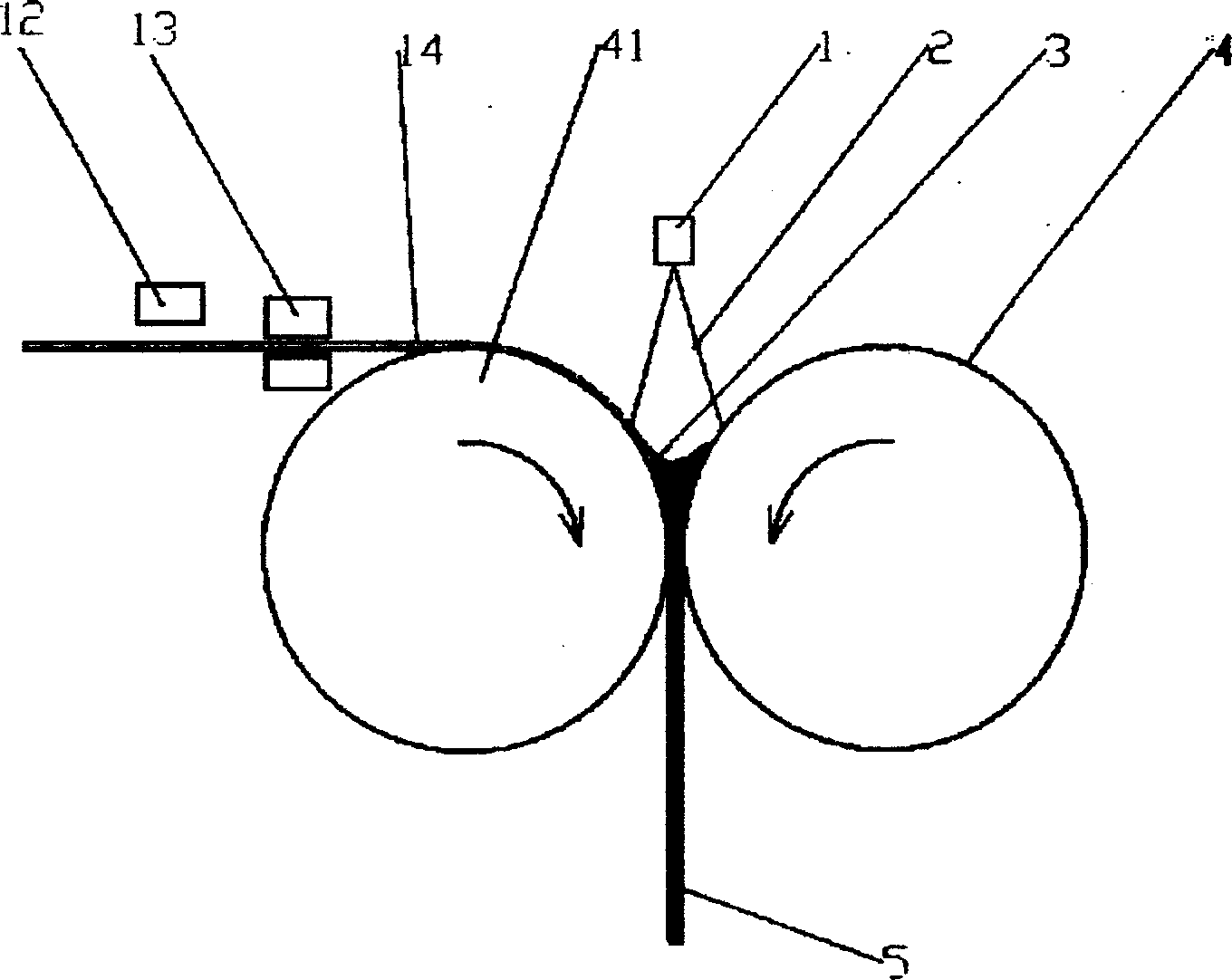

[0047]The nozzle 1 is placed above two horizontally placed rolls 4 and 41, and the interior of the rolls 4 and 41 is cooled by water, and the two sides above the gap between the rolls 4 and 41 are provided with side sealing plates 15, spraying and rolling bimetallic sheets or strips The master strip is pre-tensioned by means of twin nip rolls and take-off or helper rolls.

[0048] The atomizing nozzle can be placed directly above the gap between the two rolling rolls to spray on the mother strip 11 .

[0049] The process steps are as follows:

[0050] 1) Preparation of liquid alloy: smelt the metal to be sprayed, and control the superheat between 50 and 200 °C;

[0051] 2) Preparation of the master strip: the master strip 11 is a hot-rolled coil or a cold-rolled coil;

[0052] 3) uncoiling and flattening the master tape 11;

[0053] a) Decontamination: remove the oil stain on the surface of the master tape 11;

[0054] b) Removing the oxide layer: removing the oxide layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com