Preparation method of high-accuracy ceramic printed circuit board

A production method and technology of ceramic substrates are applied in the production of conductive lines on the surface of ceramic materials. In the field of producing high-precision conductive lines on the surface of ceramic materials, it can solve problems such as difficult industrial application, and achieve elimination of influence, reduction in width, and good edge quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Soak the 96% alumina ceramic piece as a whole in 1mol / L palladium acetate solution at room temperature for 5 minutes, take it out and dry it.

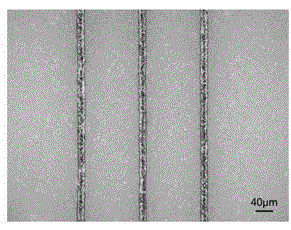

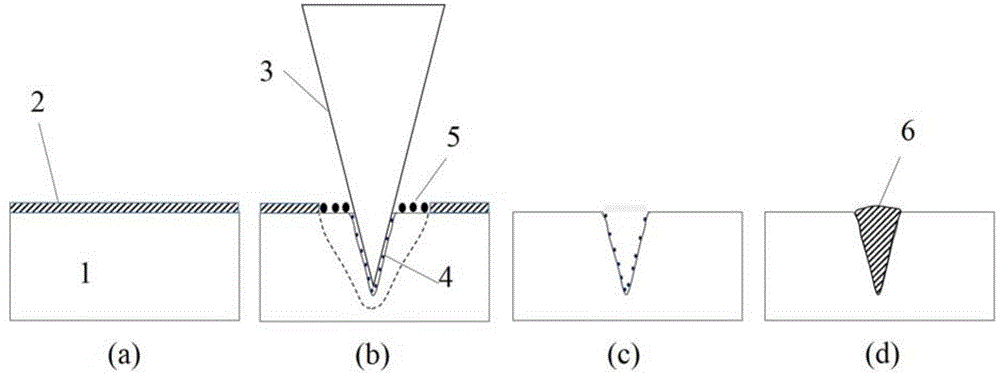

[0040] (2) The alumina ceramic sheet covered with palladium acetate film was modified by ultraviolet nanosecond pulsed laser. The laser source adopts ultraviolet pulse Nd:YVO with a maximum output power of 10W, a pulse width of 20-40ns, a pulse repetition frequency of 25-100kHz, and a wavelength of 355nm. 4 laser. The ceramic sheet is placed on the workbench of a three-axis linkage CNC machine tool and fixed by a negative pressure adsorption device. The laser beam scans the surface of the substrate according to a predetermined line pattern after passing through a beam expander, a scanning galvanometer and an f-theta lens. During laser surface modification, control the laser energy density above the ceramic modification threshold. When the laser output power is 2W (the power density of the laser is 1.13×10 6 W / cm 2), the...

Embodiment 2

[0044] (1) Soak the 99% alumina ceramic piece as a whole in 0.5mol / L palladium chloride solution, the soaking temperature is room temperature, and the soaking time is 5 minutes, take it out and dry it.

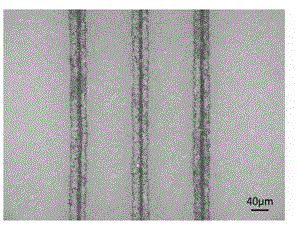

[0045] (2) A nanosecond pulsed laser is used to modify the alumina ceramic sheet covered with a palladium chloride thin film. The laser source is a pulsed fiber laser with a maximum output power of 50W, a pulse width of 120ns, a pulse repetition frequency of 50kHz, and a wavelength of 1064nm. The ceramic sheet is placed on the workbench of a three-axis linkage CNC machine tool and fixed by a negative pressure adsorption device. The laser beam scans the surface of the substrate according to a predetermined line pattern after passing through a beam expander, a scanning galvanometer and an f-theta lens. During laser surface modification, control the laser energy density above the ceramic modification threshold. When the laser output power is 10.8W (the power density of the lase...

Embodiment 3

[0049] (1) Coat an aqueous solution containing 0.1 mol / L palladium chloride on the position of the designed circuit pattern on the surface of the aluminum nitride ceramic sheet, and dry it naturally.

[0050] (2) Using ultraviolet nanosecond pulsed laser to modify the aluminum oxide ceramic sheet covered with palladium chloride thin film. The laser source adopts ultraviolet pulse Nd:YVO with a maximum output power of 10W, a pulse width of 20-40ns, a pulse repetition frequency of 25-100kHz, and a wavelength of 355nm. 4 laser. The ceramic sheet is placed on the workbench of a three-axis linkage CNC machine tool and fixed by a negative pressure adsorption device. The laser beam scans the surface of the substrate according to a predetermined line pattern after passing through a beam expander, a scanning galvanometer and an f-theta lens. During laser surface modification, control the laser energy density above the ceramic modification threshold. When the laser output power is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com