Edge cleaning method of ultraviolet laser thin-film solar battery

A technology of solar cells and ultraviolet lasers, applied to laser welding equipment, circuits, electrical components, etc., can solve problems such as waste, achieve the effects of reduced use costs, high edge cleaning efficiency, and improved laser energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

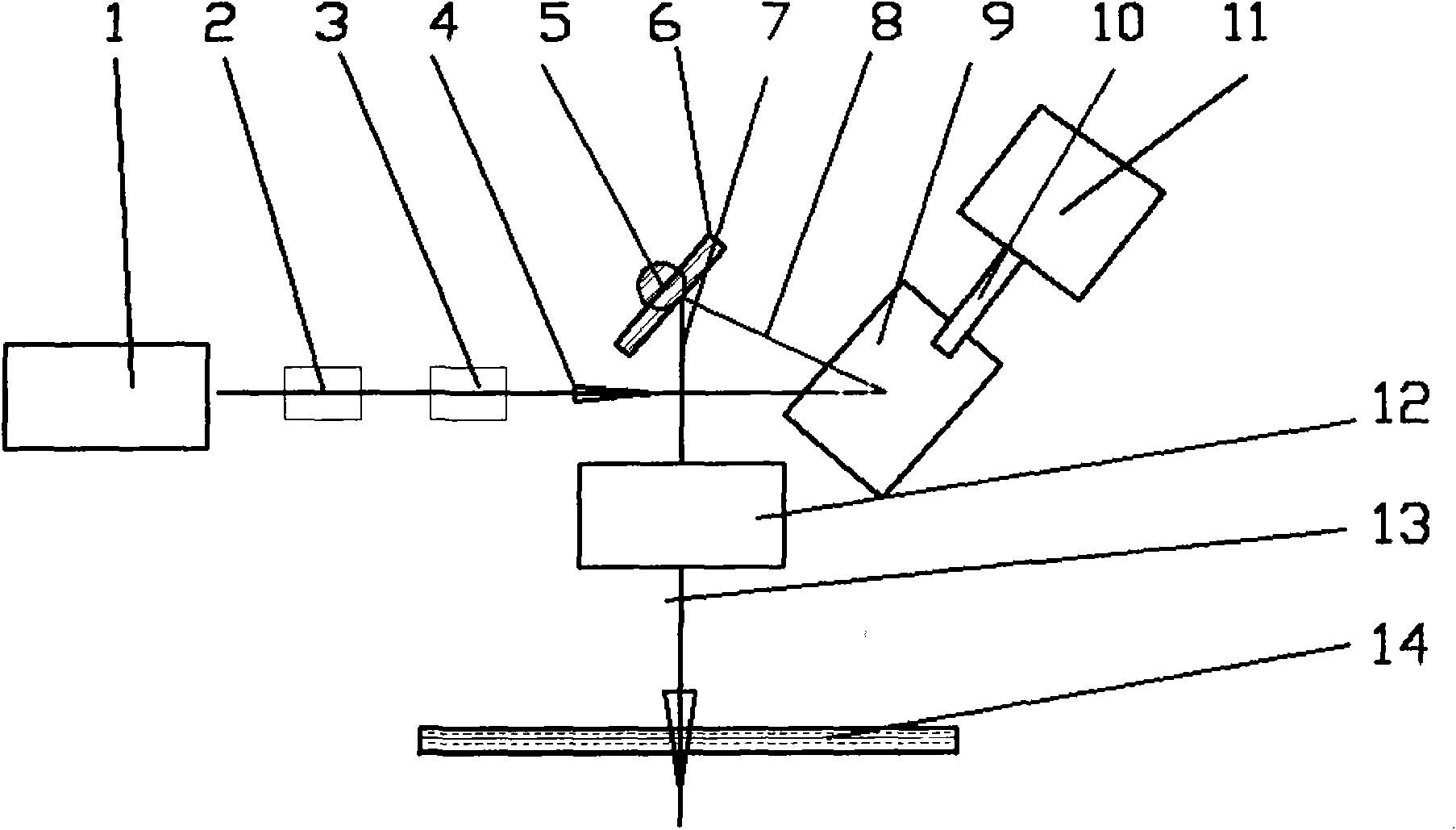

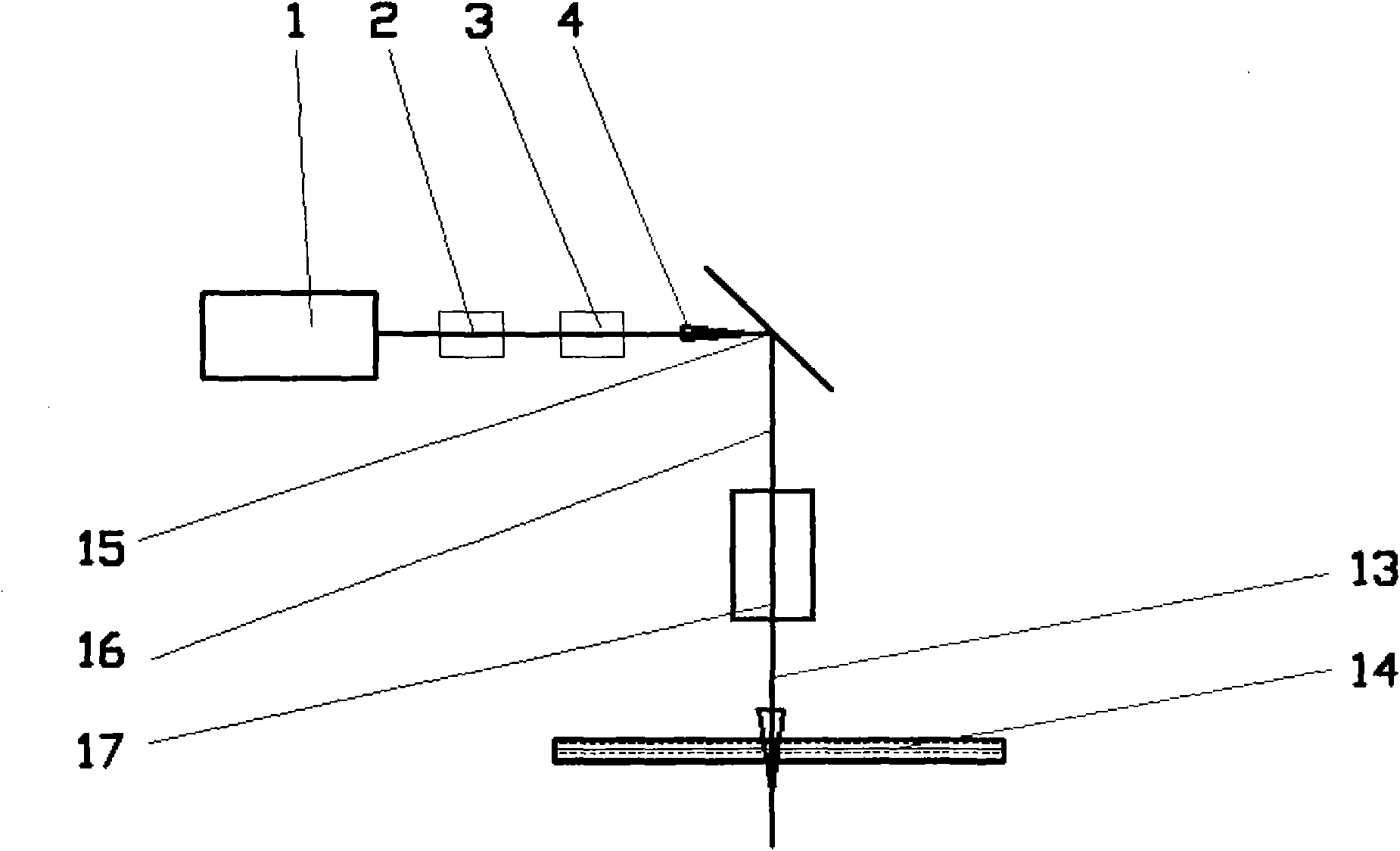

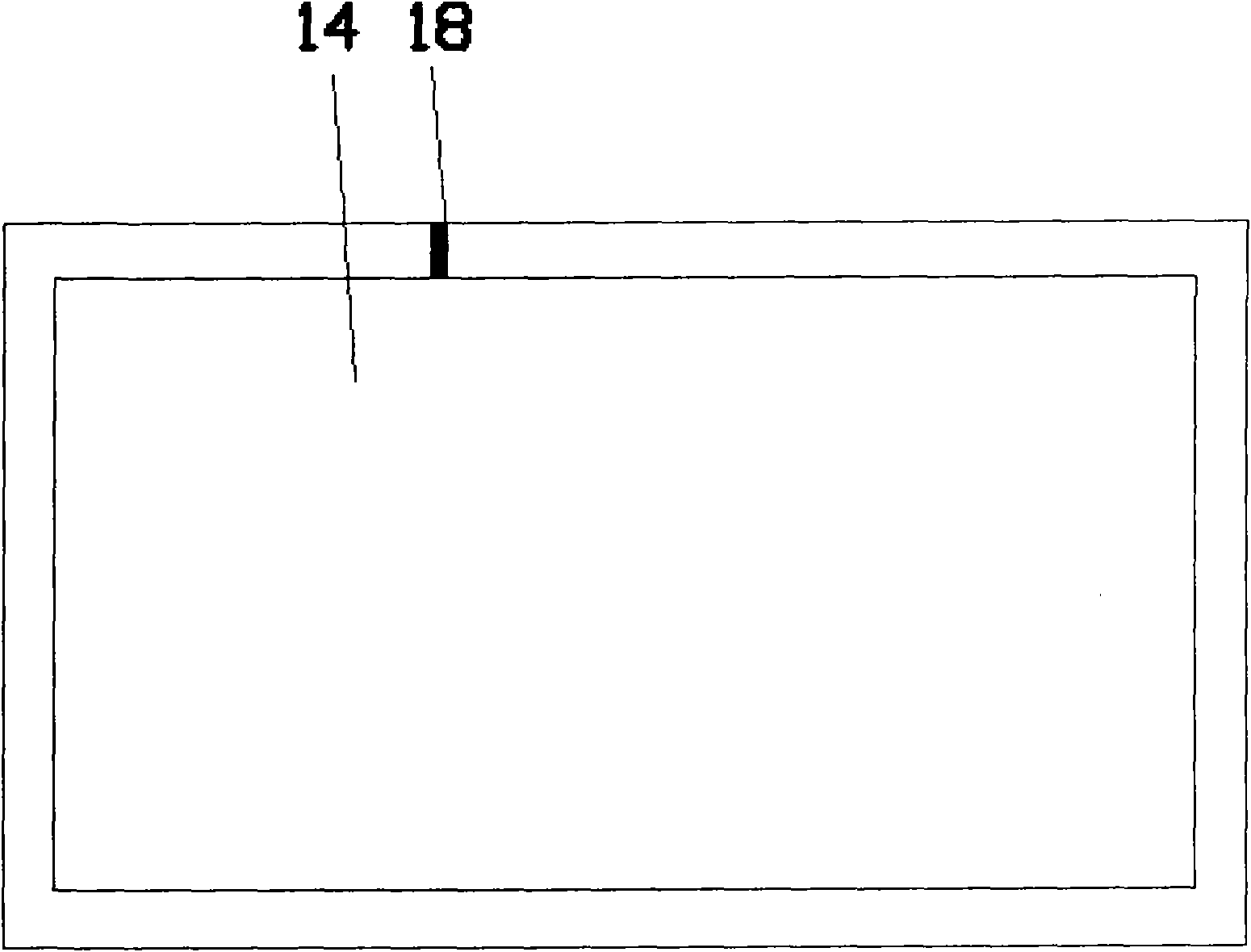

[0019] See figure 1 As shown, this is an embodiment of a method for clearing the edge of a ultraviolet laser thin film solar cell of the present invention. The material 14 to be processed is an amorphous silicon thin film solar glass cell substrate, and 1 is an ultraviolet laser with a wavelength of 355nm and a pulse repetition frequency of 30KHz. The average power is 12W, the pulse width is 18ns, the beam quality factor is less than 1.1, 2 is a 5-magnification laser beam expander, which expands the incident beam and collimates the beam, and the beam diameter is 5 mm, and 3 is the laser flat-top element, which shapes the collimated laser beam into Flat top beam, its output beam 4 is incident on the first reflective lens 9 of the vibrating mirror, 9 is clamped by the main shaft 10 of the vibrating mirror motor 11, 4 is reflected by 9, the output beam 8, 8 is reflected by the reflector 6 to form a beam 7, and the reflection The mirror 6 is fixed on the main shaft of the vibratin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com