Covering machine of door with T-shaped opening

A coating machine and glue machine technology, applied in the direction of manufacturing tools, wood processing equipment, adhesive application devices, etc., can solve the problems of waste of edge banding, uneven glue application, low production efficiency, etc., to improve the adhesive effect, Improve production efficiency and speed up processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

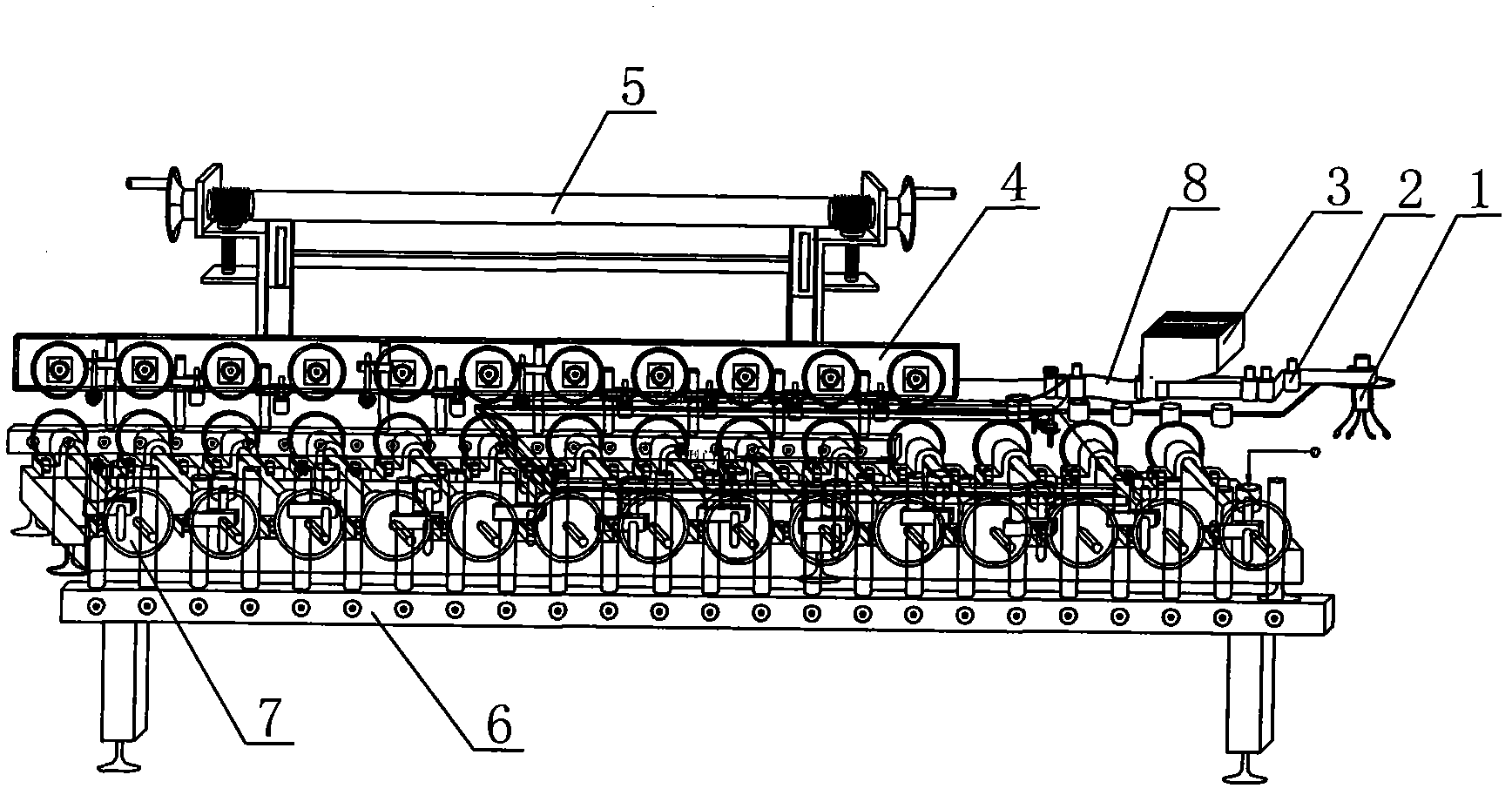

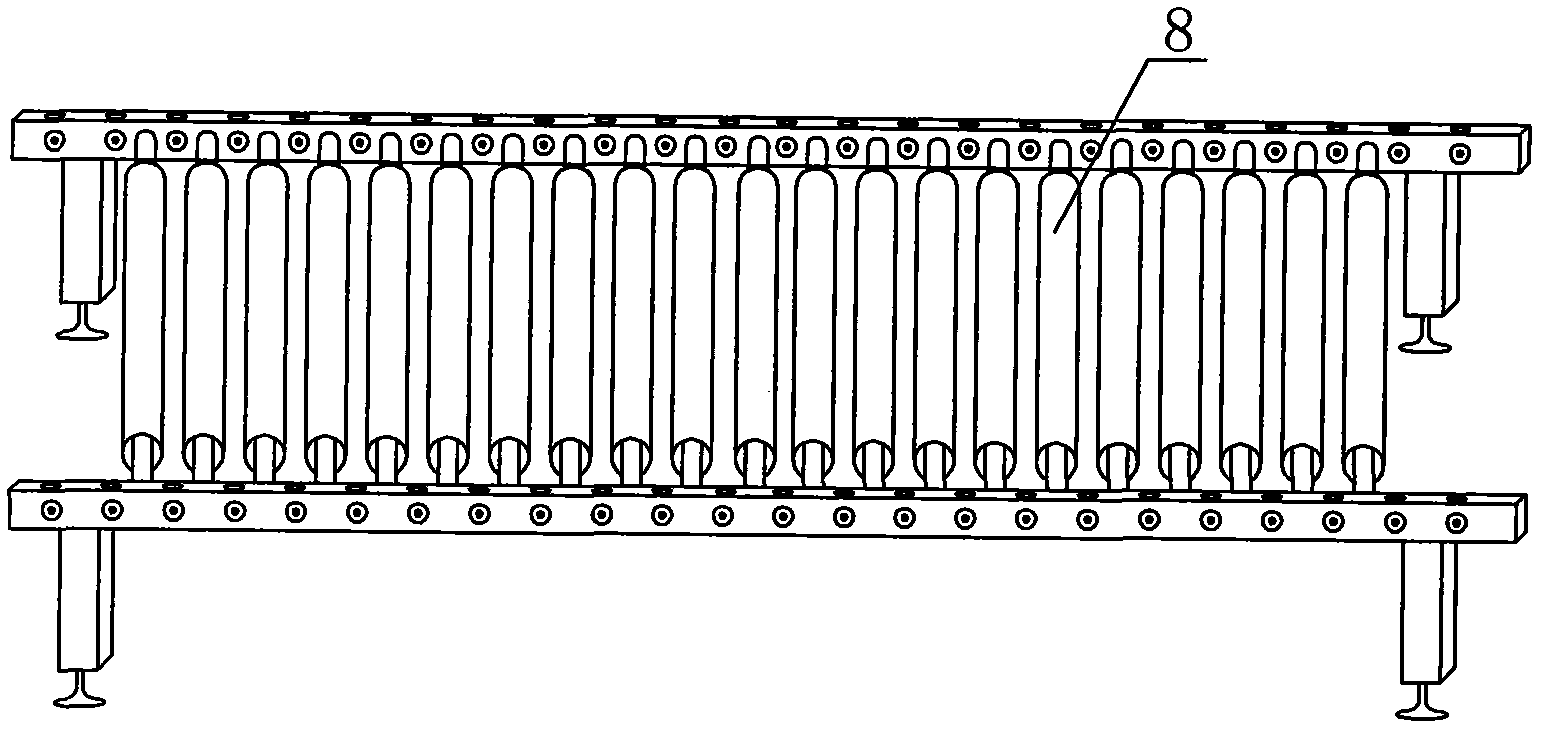

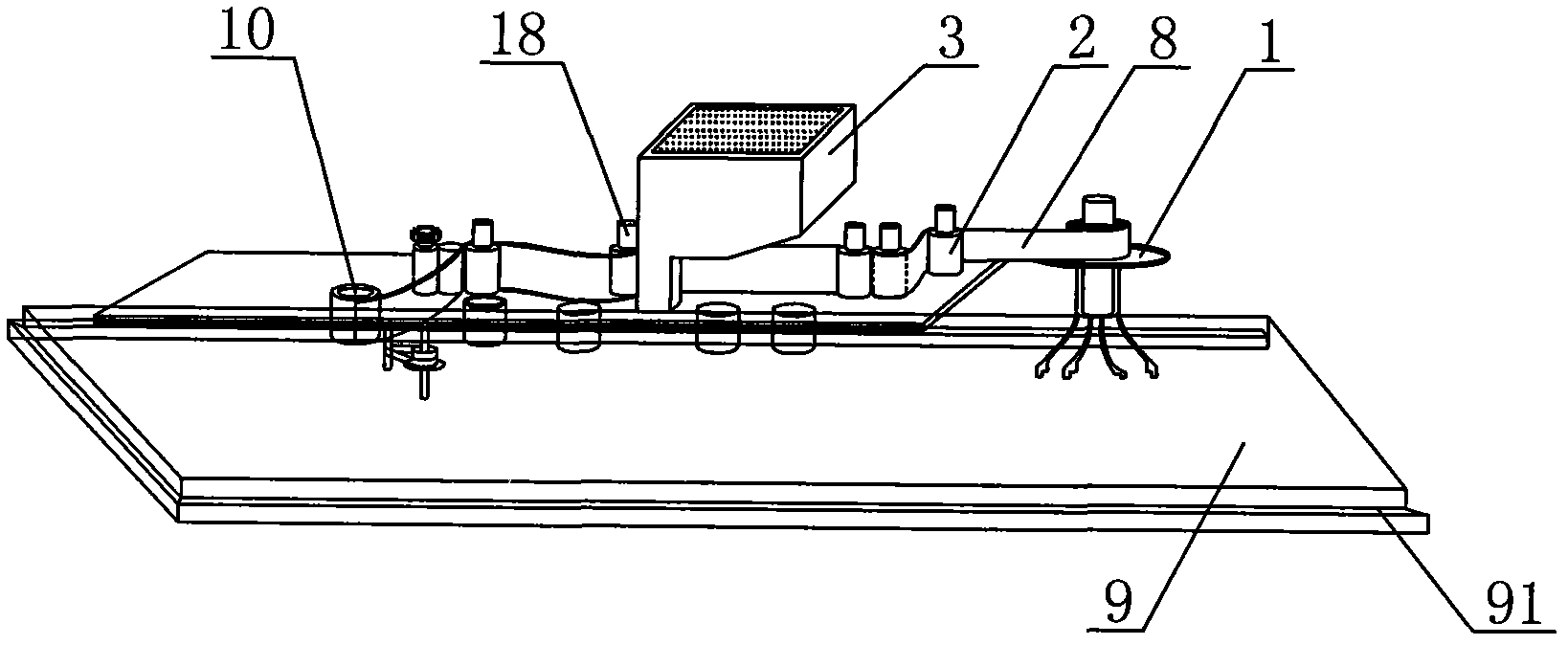

[0035] The following is based on Figures 1 to 8 Shown, the embodiment of the present invention is stated:

[0036] Such as Figures 1 to 8 As shown, taking the processing of a T-shaped door as an example, a cladding machine for a T-shaped door includes a power unit, a conveying table, a feeding frame, a material receiving frame and a gluing device. The gluing device is a vertical glue machine 3 , the vertical glue machine 3 is located on the glue side of the front end of the conveyor table, the front end of the vertical glue machine 3 is provided with a vertical feeding roller 1, the glue outlet of the vertical glue machine 3 is provided with a glue roller 18, and the front and back of the glue roller 18 Tensioning rollers 2 are respectively provided, and the glue-coating side of the conveying table is provided with a number of pressure wheels 10, heating devices and a top mouth wheel 15, the heating device is a blower 17, and the arc edge of the top mouth wheel 15 is diamon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com