Aluminum alloy sheet for DR can body and manufacturing method therefor

A technology of an aluminum alloy plate and a manufacturing method, which is applied in the field of aluminum alloy for DR tank body and its manufacturing, can solve the problems of being unsuitable for DR tank use, reducing rolling speed, and increasing manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

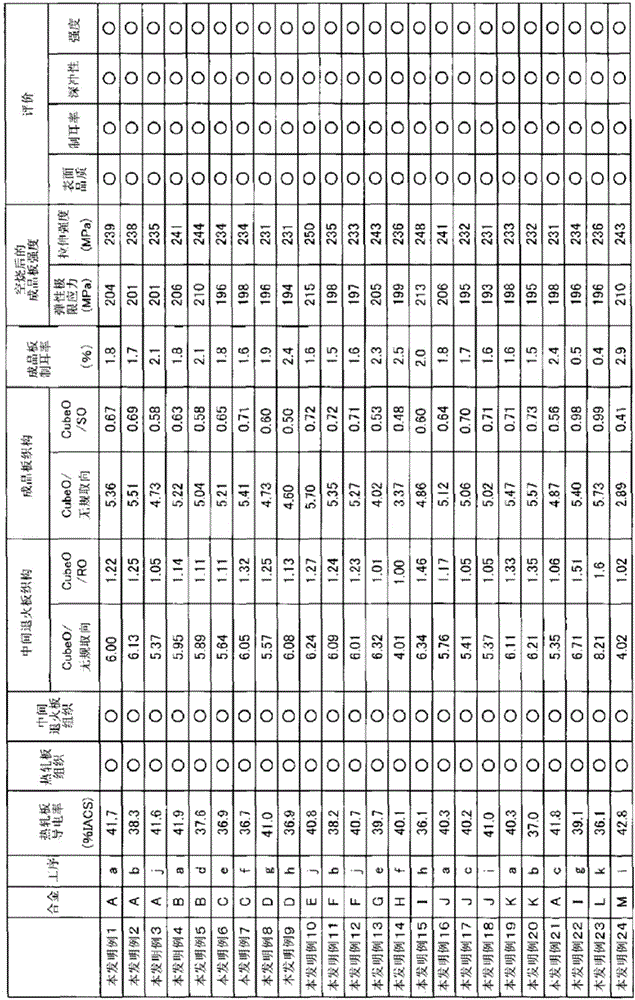

[0079] Examples of the present invention will be described based on the examples of the present invention and comparative examples described below. These examples are merely examples for illustrating one embodiment of the present invention, and the present invention is not limited thereto.

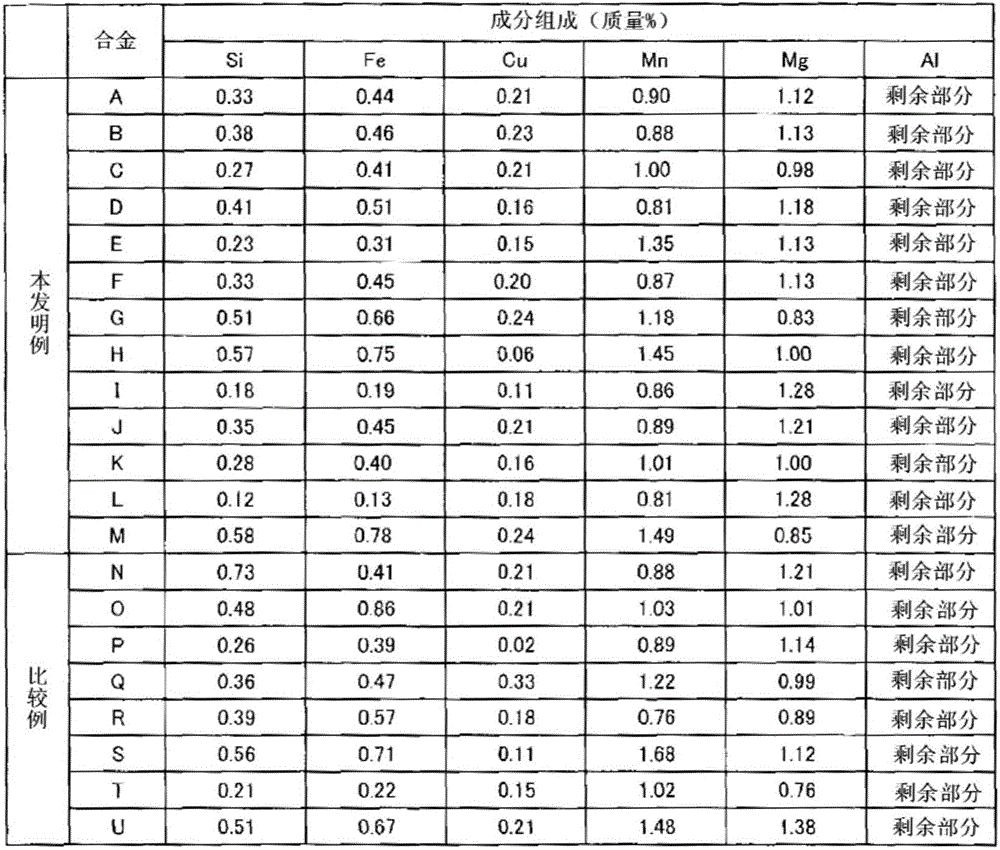

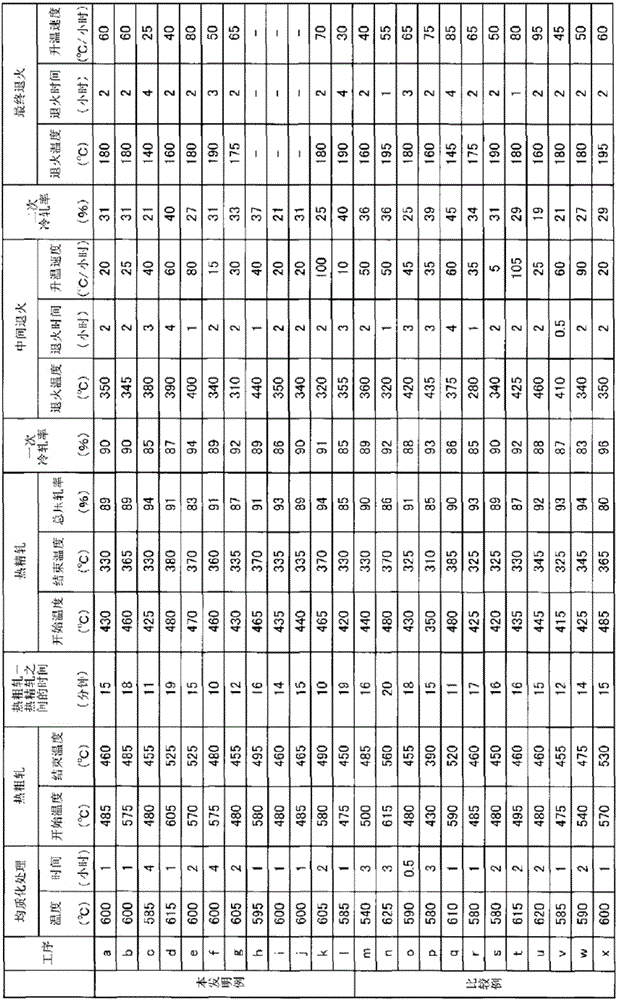

[0080] Aluminum alloys having compositions of A to U shown in Table 1 were used to produce ingots by DC casting according to a normal method. The ingots were subjected to homogenization treatment, hot rolling, primary cold rolling, intermediate annealing, secondary cold rolling, and final annealing under the conditions shown in Table 2, respectively, to manufacture final products with a thickness of 0.22 mm.

[0081] [Table 1]

[0082]

[0083] [Table 2]

[0084]

[0085] Evaluations were carried out for hot-rolled, intermediate-annealed and finished plates. First, electrical conductivity measurement and structure observation were performed on the hot-rolled sheet. The electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com