Aluminum alloy material of two-piece can body of pop-top can and production method for aluminum alloy material

An aluminum alloy material and production method technology, applied in the field of aluminum alloy manufacturing, can solve the problems of product surface quality risks, uneven separation of oil and water, product surface oxidation, etc., so as to reduce the probability of surface quality defects and reduce the number of machine times. , the effect of reducing the probability of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

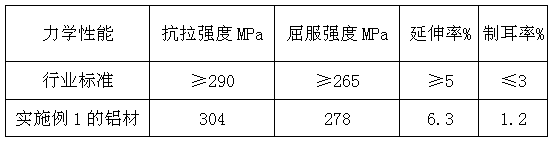

Embodiment 1

[0021] The alloy state of the aluminum body of the easy-pull 2-piece can body described in this example: 3104H19; the thickness of the finished product: 0.26mm; the production process includes: melting and casting→sawing→homogenization treatment→hot rolling→cold continuous rolling→edge trimming→ Packaging, the specific process parameters are as follows:

[0022] casting

[0023] The mass percentage of the chemical composition of molten aluminum is: Si: 0.170, Fe: 0.350, Cu: 0.100, Mn: 0.800, Mg: 1.280, Cr: 0.03, Zn: 0.041, Ti: 0.02, single ≤ 0.02%, total ≤ 0.10 %; the rest is Al; the melting temperature is 760°C, the refining temperature is 750°C, and the casting temperature is 680°C.

[0024] Homogenization (heating)

[0025] The ingot is kept at 570-606°C for 10-15 hours, then turned to 480-505°C for 2-5 hours.

[0026] hot rolled

[0027] Use 1+4 hot rolling production line, one reversible roughing mill plus one four-stand hot continuous rolling production line; hot rou...

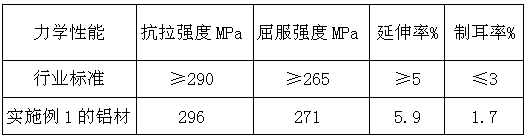

Embodiment 2

[0040] The alloy state of the aluminum body of the easy-pull 2-piece can body described in this embodiment: 3104H19; 0.24mm; its production process includes: melting and casting→sawing and milling→homogenization treatment→hot rolling→cold continuous rolling→edge trimming→packaging, specifically The process parameters are as follows:

[0041] casting

[0042] The mass percentage of the chemical composition of molten aluminum water is: Si: 0.300%, Fe: 0.500%, Cu: 0.250%, Mn: 0.920%, Mg: 1.100%, Cr: 0.015%, Zn: 0.05%, Ti: 0.017%, Single ≤0.02%, total ≤0.10%; the rest is Al; the melting temperature is 720°C, the refining temperature is 720°C, and the casting temperature is 710°C.

[0043] homogenization heating

[0044] The ingot is kept at 570-606°C for 10-15 hours, then turned to 480-505°C for 2-5 hours.

[0045] hot rolled

[0046] Use 1+4 hot rolling production line, one reversible roughing mill plus one four-stand hot continuous rolling production line; hot roughing mill ...

Embodiment 3

[0058] The alloy state of the aluminum body of the easy-pull 2-piece can body described in this example: 3104H19; the thickness of the finished product: 0.38mm; the production process includes: melting and casting→sawing→homogenization treatment→hot rolling→cold continuous rolling→edge trimming→ Packaging, the specific process parameters are as follows:

[0059] casting

[0060] The mass percentage of the chemical composition of molten aluminum is: Si: 0.237, Fe: 0.429, Cu: 0.225, Mn: 0.896, Mg: 1.260, Cr: 0.026, Zn: 0.041, Ti: 0.017, single ≤ 0.02%, total ≤ 0.10 %; the rest is Al; the melting temperature is 755°C, the refining temperature is 728°C, and the casting temperature is 684°C.

[0061] Homogenization (heating)

[0062] The ingot is kept at 570-606°C for 10-15 hours, then turned to 480-505°C for 2-5 hours.

[0063] hot rolled

[0064] Use 1+4 hot rolling production line, one reversible roughing mill plus one four-stand hot continuous rolling production line; hot r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com