Engineering process for producing low-iron low-silicon 3004 alloy by directly cast-rolling electrolytic aluminium liquid

An electrolytic aluminum liquid, engineering technology, applied in the field of aluminum processing, can solve the problems of affecting the cold rolling process, cracked edges, uneven crystallization of alloy blanks, etc., to achieve excellent mechanical properties and processing properties, size and quantity reduction, finished products Flattening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

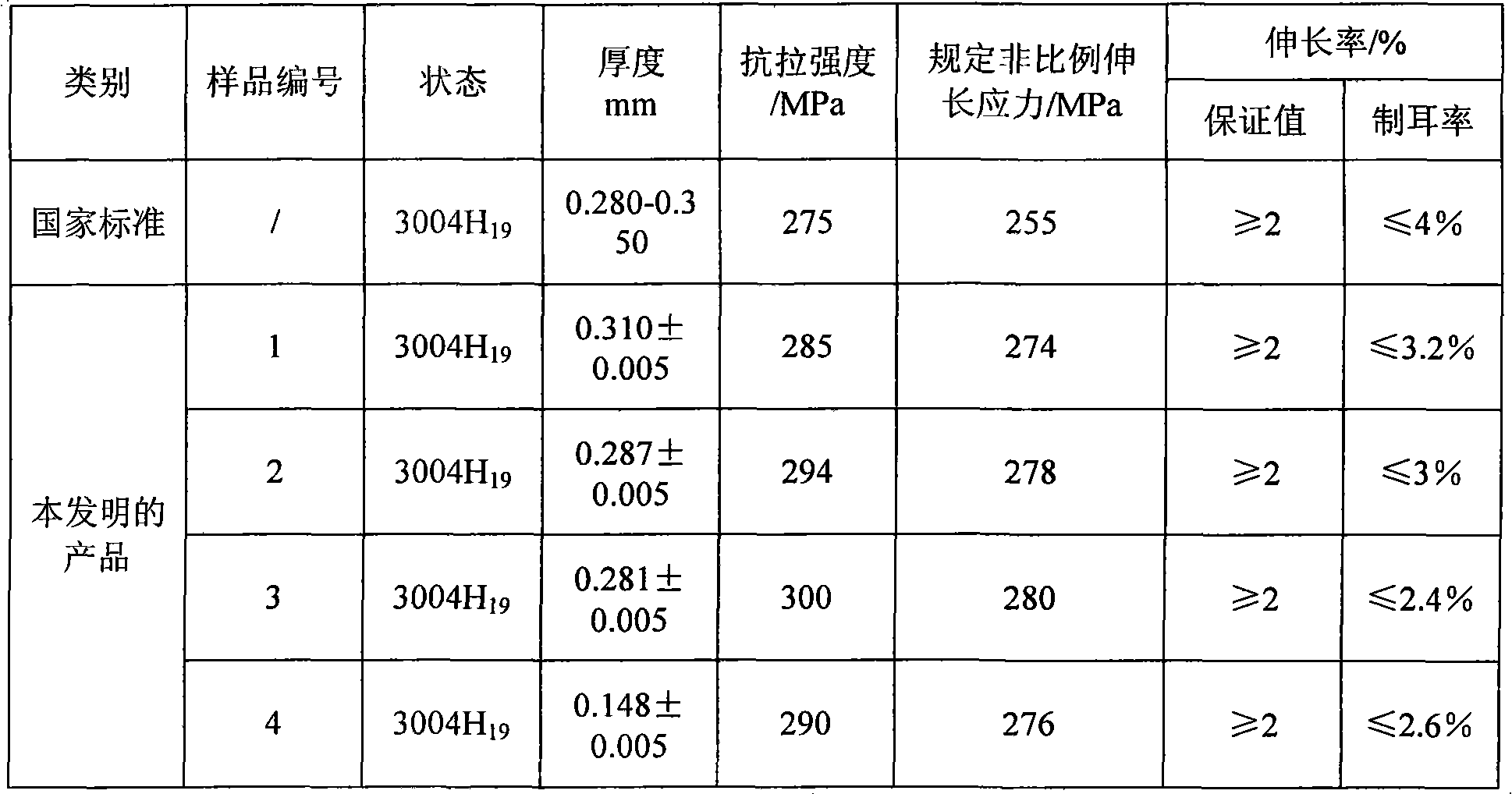

Examples

Embodiment 1

[0037] ① The composition of the present invention includes: silicon 0.12%, iron 0.43%, copper 0.09%, manganese 1.1%, magnesium 0.9%, zinc≤0.20%, titanium 0.02%, and the rest is aluminum.

[0038] What adopt is 60-70% electrolytic aluminum liquid, 30-40% aluminum ingot or aluminum scrap.

[0039] ② Melting and refining

[0040] During the melting process, use a forklift to stir 1-2 times, melt at an accelerated rate, and the time interval is 30 minutes. Stir for 4-5 minutes after levelling, and control the stirring temperature at 750-760°C.

[0041] The first refinement adopts argon spray powder refining, and the second refinement adopts a special argon and carbon tetrachloride combined device for on-line refining. After the refining is completed, the slag is removed and the composition is adjusted.

[0042] Start adding manganese ingots after complete stirring. After the stirring is completed, the process of the present invention preferably adopts No. 2 refining agent and ...

Embodiment 2

[0057] ① The composition of the present invention includes: silicon 0.07%, iron 0.28%, copper 0.06%, manganese 1.0%, magnesium 0.8%, zinc≤0.20%, titanium 0.015-0.03%, and the rest is aluminum.

[0058] What adopt is 60-70% electrolytic aluminum liquid, 30-40% aluminum ingot or aluminum scrap.

[0059] ② Melting and refining

[0060] During the melting process, use a forklift to stir 1-2 times, melt at an accelerated rate, and the time interval is 30 minutes. Stir for 4-5 minutes after levelling, and control the stirring temperature at 750-755°C.

[0061] The first refinement adopts argon spray powder refining, and the second refinement adopts a special argon and carbon tetrachloride combined device for on-line refining. After the refining is completed, the slag is removed and the composition is adjusted.

[0062] Start adding manganese ingots after complete stirring. After the stirring is completed, the process of the present invention preferably adopts No. 2 refining agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com