Multiple-energy-field asymmetric sunken type cast-rolling method for preparing aluminium alloy plates and strips for deep drawing

An aluminum alloy strip, asymmetric technology, applied in casting equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of high efficiency, low production cost, short production process, etc., and achieve low anisotropy index, production cost Effect of reduction and improvement of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

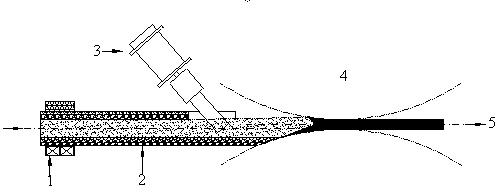

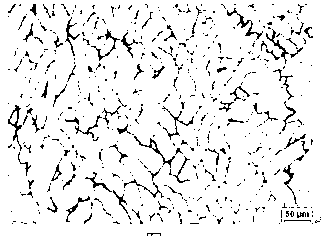

[0026] According to the composition ratio of 1060 aluminum alloy, take the material and put it into the melting furnace for melting, the temperature is 710 ° C, while the aluminum alloy is melting, heat the front box and launder to 650 ° C, and keep it warm for 20 minutes after the aluminum alloy melting is completed , so that the temperature of each part of the melt is uniform, the melting furnace is tilted, so that the aluminum alloy melt flows into the front box through the launder, and the flow of the melt is controlled so that the liquid level of the melt in the front box is kept at a position 5mm above the center line of rolling , and then flow into the asymmetric nozzle 2 (the upper nozzle plate is 20mm shorter than the lower nozzle plate, and the center plane of the nozzle is 4mm lower than the rolling centerline), and enter the roll 4 under the action of the electromagnetic 1 / ultrasonic 3 energy field In the casting and rolling area of the joint (the roll gap is 5.0 ...

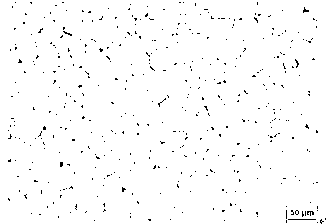

Embodiment 2

[0028] According to the composition ratio of 1050 aluminum alloy, take the material and put it into the melting furnace for melting, the temperature is 715°C, while the aluminum alloy is melting, heat the front box and launder to 620°C, and keep it warm for 20 minutes after the aluminum alloy melting is completed , so that the temperature of each part of the melt is uniform, the melting furnace is tilted, so that the aluminum alloy melt flows into the front box through the launder, and the flow of the melt is controlled so that the liquid level of the melt in the front box is kept at a position 4mm above the center line of rolling , and then flow into the asymmetric nozzle 2 (the upper nozzle plate is 30mm shorter than the lower nozzle plate, and the center plane of the nozzle is 5mm lower than the rolling centerline), and enter the roll 4 under the action of the electromagnetic 1 / ultrasonic 3 energy field The casting and rolling area of the joint (the roll gap is 3.5 mm), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com