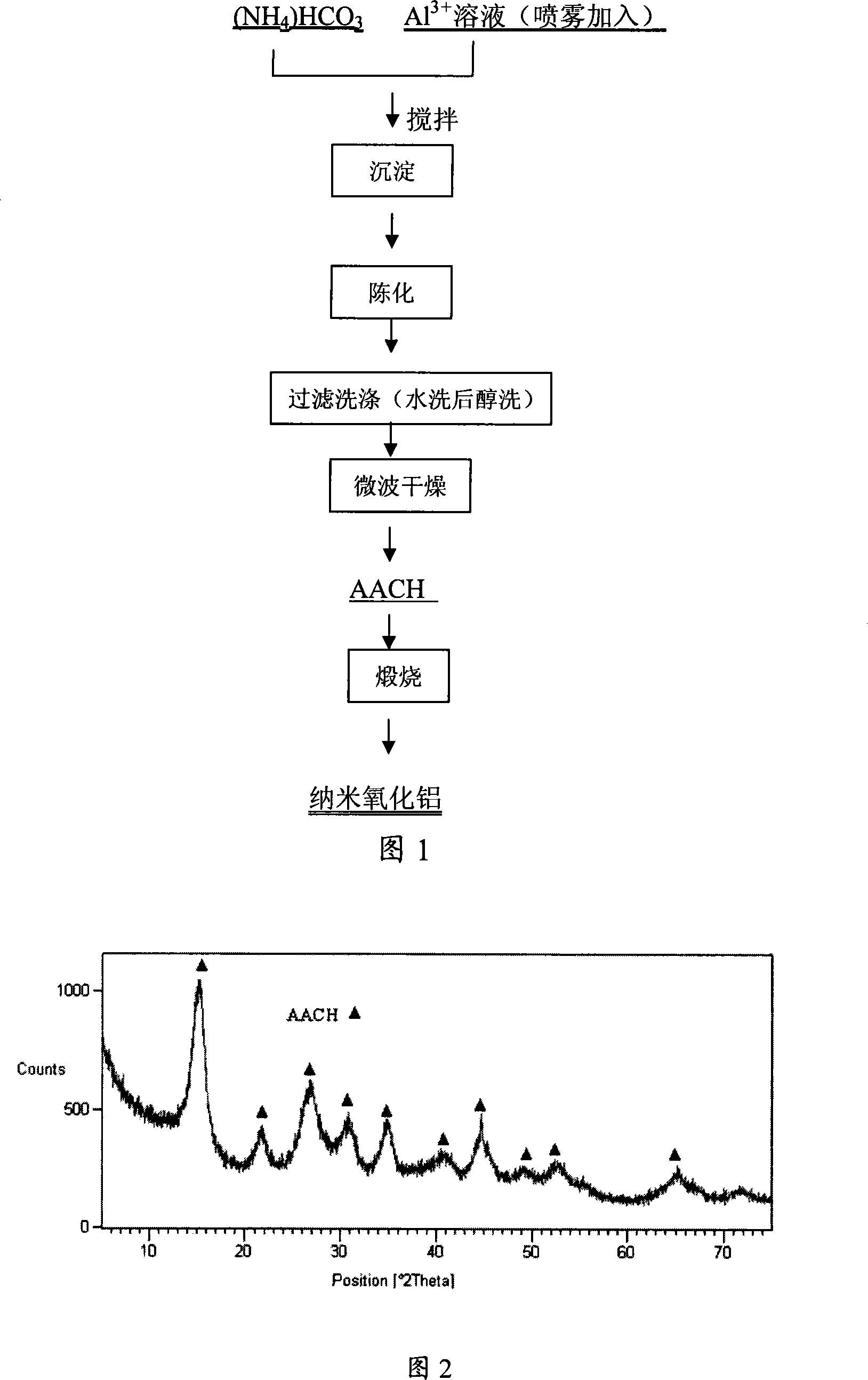

Method for preparing nano aluminum oxide powder

A nano-alumina and powder technology, applied in alumina/hydroxide preparation, nanotechnology, nanotechnology and other directions, can solve the problems of easy agglomeration of powder, low drying efficiency, slow feeding speed, etc. The effect of explosive nucleation, fast feeding and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

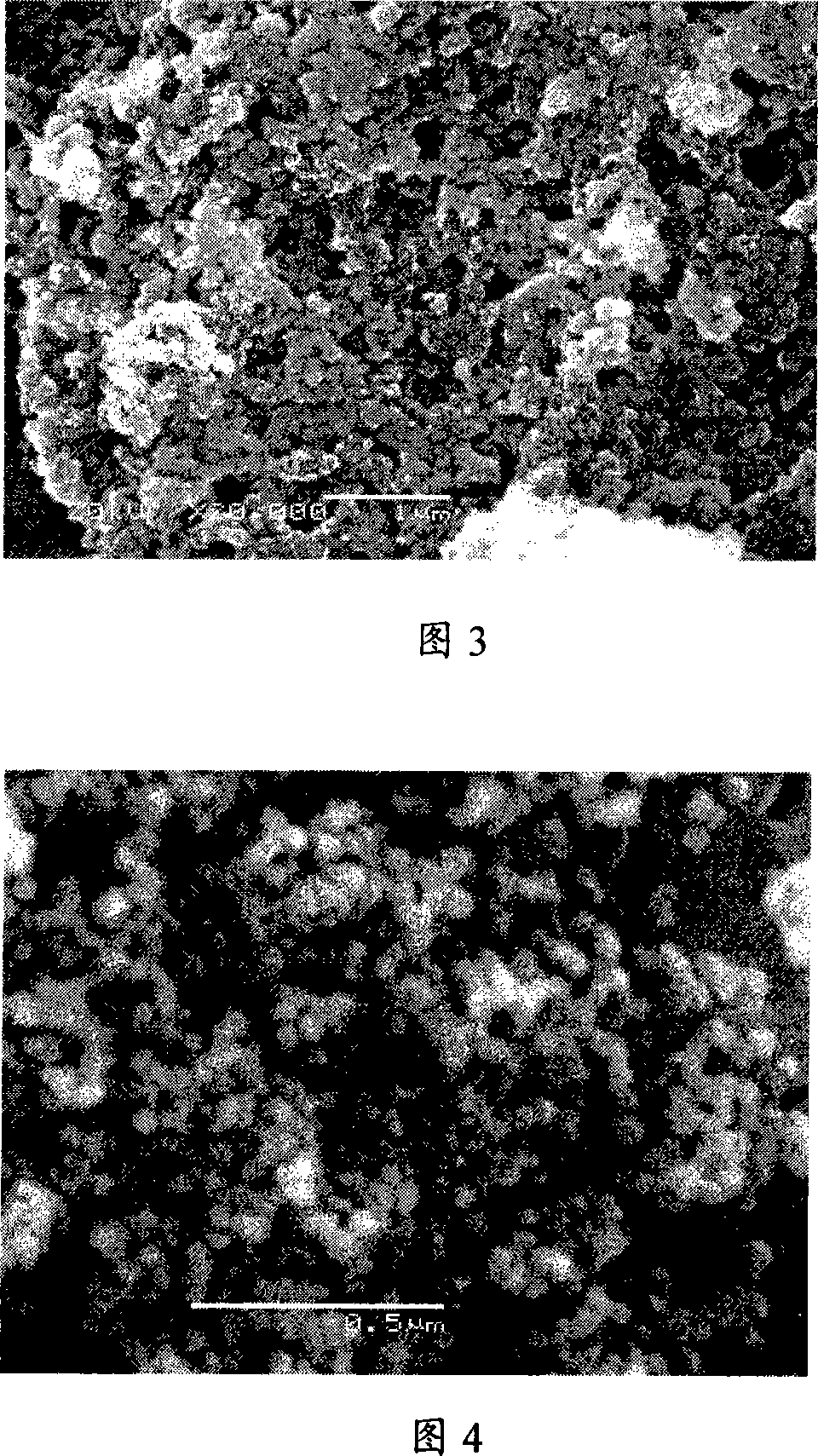

Embodiment 1

[0028] Al(NO 3 ) 3 The concentration is 0.2mol / L; (NH 4 )HCO 3 The initial concentration of the solution is 2.5mol / L, and the pH value is adjusted to 9.5 with ammonia water; the spray feed rate is 0.4ml / min on the average per square centimeter of the liquid surface area of the ammonium bicarbonate solution by using a sprayer that can control the flow rate. ; (NH 4 )HCO 3 The solution was stirred by strong magnetic force, the stirring speed was 1200r / min, and the reaction time was 2.5h. Add 1% polyethylene glycol in the ammonium bicarbonate solution, (NH 4 )HCO 3 with Al(NO 3 ) 3 The molar ratio is 6, and the temperature is 25°C. The obtained precipitate was aged for 3 hours, washed 4 times with water, then washed 3 times with absolute ethanol, and then dried in a microwave oven. The microwave oven used a power of 300W in the initial drying stage, and a power of 150W in the latter stage. The time used in the front and rear stages were respectively 10min and 30min, an...

Embodiment 2

[0030] Al(NO 3 ) 3 Concentration is 0.3mol / L; (NH 4 )HCO 3 The initial concentration of the solution is 2.5mol / L, and the pH value is adjusted to 9.6 with ammonia water; a sprayer that can control the flow rate is used, and the spray feed rate is 0.3ml / min on the average per square centimeter of the liquid surface area of the ammonium bicarbonate solution. ; (NH 4 )HCO 3 The solution was stirred by strong magnetic force, the stirring speed was 1200r / min, the reaction time was 3h, and 1.5% polyethylene glycol was added in the ammonium bicarbonate solution, (NH 4 )HCO 3 with Al(NO 3 ) 3 The molar ratio is 7, and the temperature is 25°C. The obtained precipitate was aged for 3 hours, washed 4 times with water, then washed 3 times with absolute ethanol, and then dried in a microwave oven. The microwave oven used a power of 300W in the initial drying stage, and a power of 150W in the latter stage. The time used in the front and rear stages were respectively 10min and 30m...

Embodiment 3

[0032] al 2 (SO 4 ) 3 The concentration is 0.2mol / L; (NH 4 )HCO 3 The initial concentration of the solution is 2.5mol / L, and the pH value is adjusted to 9.6 with ammonia water; a sprayer that can control the flow rate is used, and the spray feed rate is 0.3ml / min on the average per square centimeter of the liquid surface area of the ammonium bicarbonate solution. ; (NH 4 )HCO 3 The solution was stirred by strong magnetic force, the stirring speed was 1200r / min, the reaction time was 3h, and 1.5% polyethylene glycol was added in the ammonium bicarbonate solution, (NH 4 )HCO 3 with Al(NO 3 ) 3 The molar ratio is 7, and the temperature is 25°C. The obtained precipitate was aged for 3 hours, washed 4 times with water, then washed 3 times with absolute ethanol, and then dried in a microwave oven. The microwave oven used a power of 300W in the initial drying stage, and a power of 150W in the latter stage. The time used in the front and rear stages were respectively 10min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com