System and method for synergistically removing dust and condensable particles in flue gas

A particle and flue gas technology, which is applied in the system field of collaborative removal of dust and condensable particulate matter in flue gas, can solve the problems of weak ability to remove condensable particulate matter and does not involve the removal of condensable particulate matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

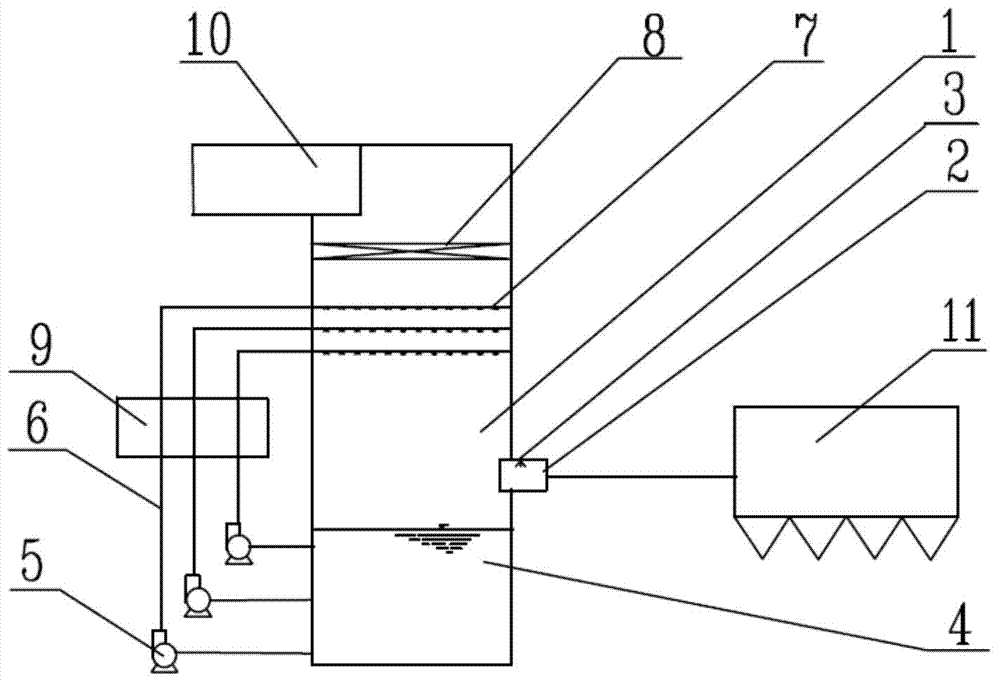

[0124] Such as figure 1 The sprinkler system shown, the process of using this system to cooperatively remove dust and condensable particulate matter in the flue gas is specifically: a coal-fired boiler, the flue gas temperature after the air preheater is 130 degrees Celsius, first passes through the micro-pressure Reverse blowing bag filter dust removal, after testing, the original flue gas dust concentration is reduced to 15mg / Nm 3 , in addition, there is 50mg / Nm in the flue gas 3 SO 3 The flue gas enters the spray tower again. At the entrance of the spray tower, a water spray cooling device is provided. The flue gas is cooled and humidified by evaporating the spray water. Become saturated wet flue gas, usually the temperature of the flue gas can drop to about 50°C. Studies have shown that SO 3 It is gaseous at 120°C, and condenses into H after humidification and cooling 2 SO 4 The droplets are quickly adsorbed on the surface of the dust particles, which improves the mo...

Embodiment 2

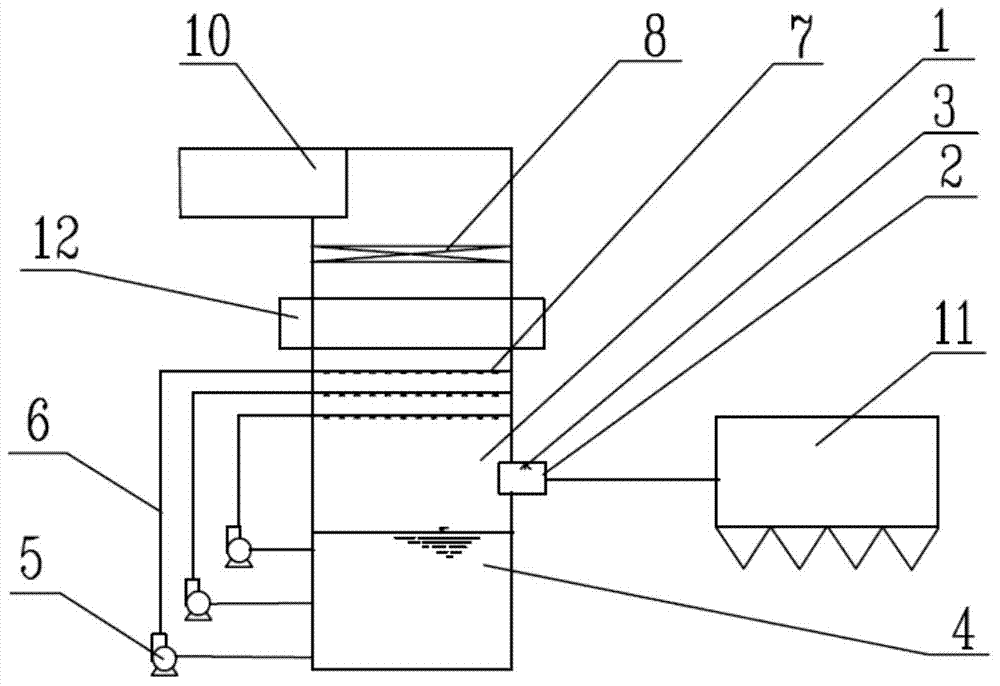

[0127] Such as figure 2 The sprinkler system shown, the process of using this system to collaboratively remove dust and condensable particles in the flue gas is as follows: a coal-fired boiler, the flue gas temperature after the air preheater is 130 ℃, first passes through the micro pressure Reverse blow bag filter dust removal, the dust concentration of the original flue gas is reduced to 15mg / Nm 3 , in addition, there is 50mg / Nm in the flue gas 3 SO 3 The flue gas enters into the spray tower of the present invention again, and at the entrance of the spray tower, a water spray cooling device is provided, and the flue gas is cooled and humidified by evaporating the spray water, and the flue gas becomes saturated wet flue gas, usually the flue gas temperature It can be reduced to about 50 degrees Celsius. The temperature of the slurry in the slurry tank is considered to be the same as that of the saturated wet flue gas, which is also 50°C, and the temperature of the humidif...

Embodiment 3

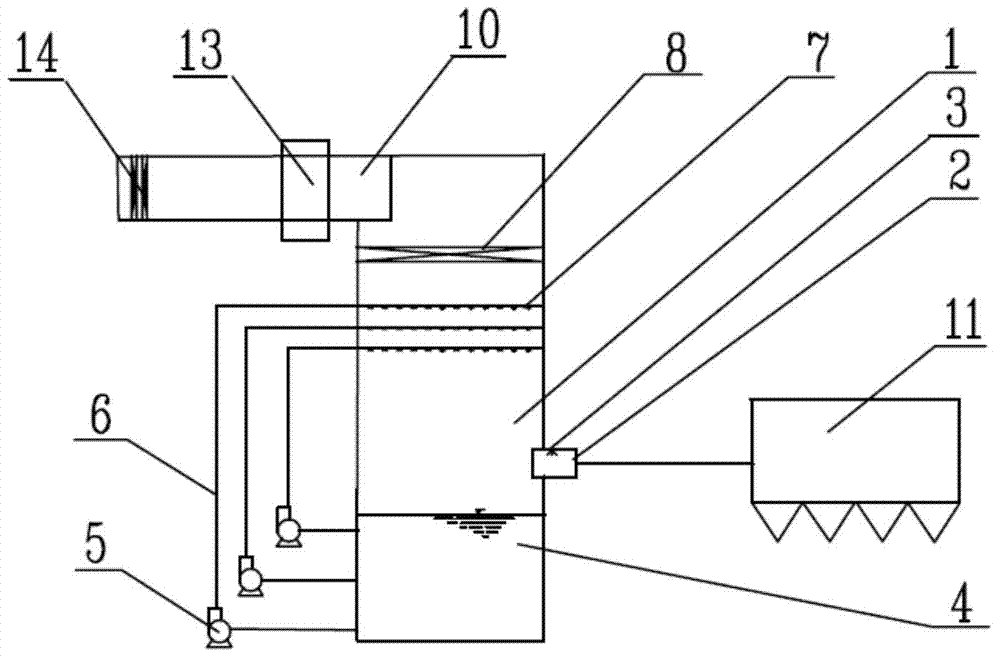

[0131] It is the same as the spraying system described in Example 1, the difference is that no heat exchanger is installed on the slurry pipe, a second finned heat exchanger is added in the clean flue, cooling water flows through the pipe, and humidified flue gas is outside the pipe, such as image 3 As shown, the humidified flue gas enters the clean flue, and after passing through the heat exchanger in the clean flue, the humidified flue gas cools down by 1°C, and the residual liquid droplets in the clean flue gas can continue to condense and grow. A clean flue demister is installed at the end of the clean flue to remove the grown droplets, and the dust concentration is further reduced to 3mg / Nm 3 , SO 3 Concentration down to 6mg / Nm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com