Solid solution thermal treatment method for high-zinc scandium-containing aluminum alloy

A solid solution heat treatment, scandium aluminum alloy technology, applied in the field of aluminum alloy heat treatment, can solve the problems of increasing difficulty of alloy formability, insufficient performance and heat treatment technology and lack of systematic, lack of theoretical basis and data accumulation, etc., to achieve increased precipitation phase. , hinder the movement of dislocations, the effect of small precipitates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

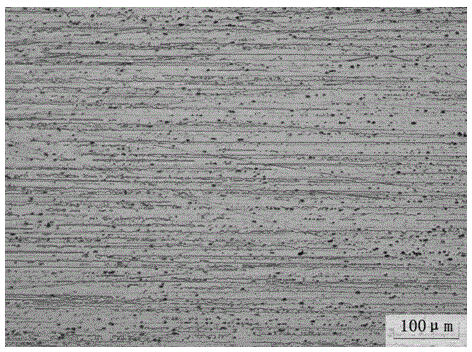

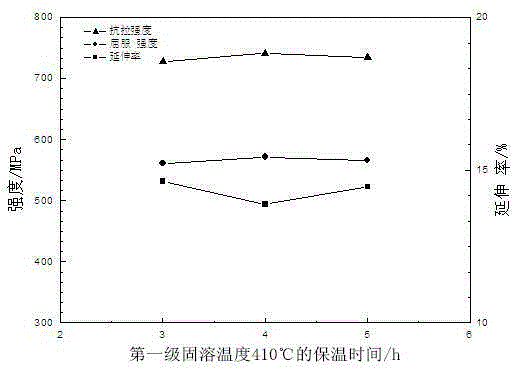

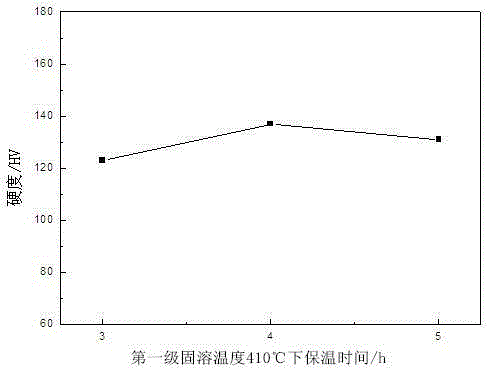

[0028] First, heat the high-zinc and scandium-containing aluminum alloy at 410°C for 3 hours, then raise the temperature to 475°C for 4 hours, transfer it to water at room temperature for 5 minutes within 10 seconds, and then perform single-stage aging heat treatment: at 120°C Keep it warm for 24.5 hours, and finally air-cool to room temperature. The metallographic structure of the high-zinc and scandium-containing aluminum alloy after solution heat treatment is as follows figure 1 shown, from figure 1 It can be seen that a large number of fine and dispersed particles are precipitated in the alloy. The mechanical properties of the high-zinc and scandium-containing aluminum alloy after solution heat treatment are shown in Fig. figure 2 As shown, the hardness as image 3 As shown in the figure, it can be seen from the figure that the tensile strength of the high-zinc and scandium-containing aluminum alloy after solution heat treatment reaches 728MPa, the yield strength reaches...

Embodiment 2

[0030] First, heat the high-zinc and scandium-containing aluminum alloy at 410°C for 4h, then raise the temperature to 475°C for 4h, transfer it to water at room temperature for 5min within 10s, and then perform single-stage aging heat treatment: at 120°C Keep it warm for 24.5 hours, and finally air-cool to room temperature. The mechanical properties of the high-zinc and scandium-containing aluminum alloy after solution heat treatment are shown in the figure figure 2 As shown, the hardness as image 3 As shown in the figure, it can be seen from the figure that the tensile strength of the high-zinc and scandium-containing aluminum alloy after solution heat treatment reaches 741MPa, the yield strength reaches 572MPa, the elongation rate reaches 13.88%, and the hardness reaches 137Hv. Performance has been significantly improved.

Embodiment 3

[0032] First, heat the high-zinc and scandium-containing aluminum alloy at 410°C for 5 hours, then raise the temperature to 475°C for 4 hours, transfer it to water at room temperature for 5 minutes within 10 seconds, and then perform single-stage aging heat treatment: at 120°C Keep it warm for 24.5 hours, and finally air-cool to room temperature. The mechanical properties of the high-zinc and scandium-containing aluminum alloy after solution heat treatment are shown in the figure figure 2 As shown, the hardness as image 3 As shown in the figure, it can be seen from the figure that the tensile strength of the high-zinc and scandium-containing aluminum alloy after solution heat treatment reaches 734MPa, the yield strength reaches 566MPa, the elongation rate reaches 14.46%, and the hardness reaches 131Hv. Performance has been significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com