Manufacturing method for producing aluminum alloy structural part for air cushion furnace production vehicle

A manufacturing method and aluminum alloy technology are applied in the field of manufacturing aluminum alloy structural parts for vehicles produced by air cushion furnaces, which can solve the problems of poor bending performance and low mechanical strength, and achieve good bending formability, reduced vehicle body weight, and good strength. and the effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

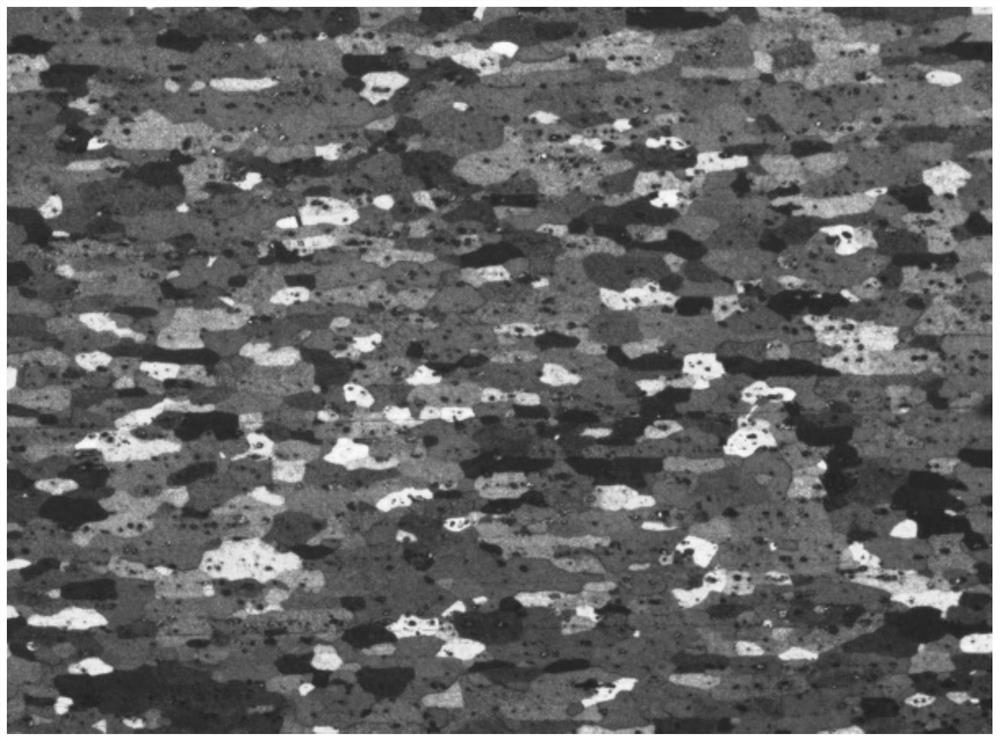

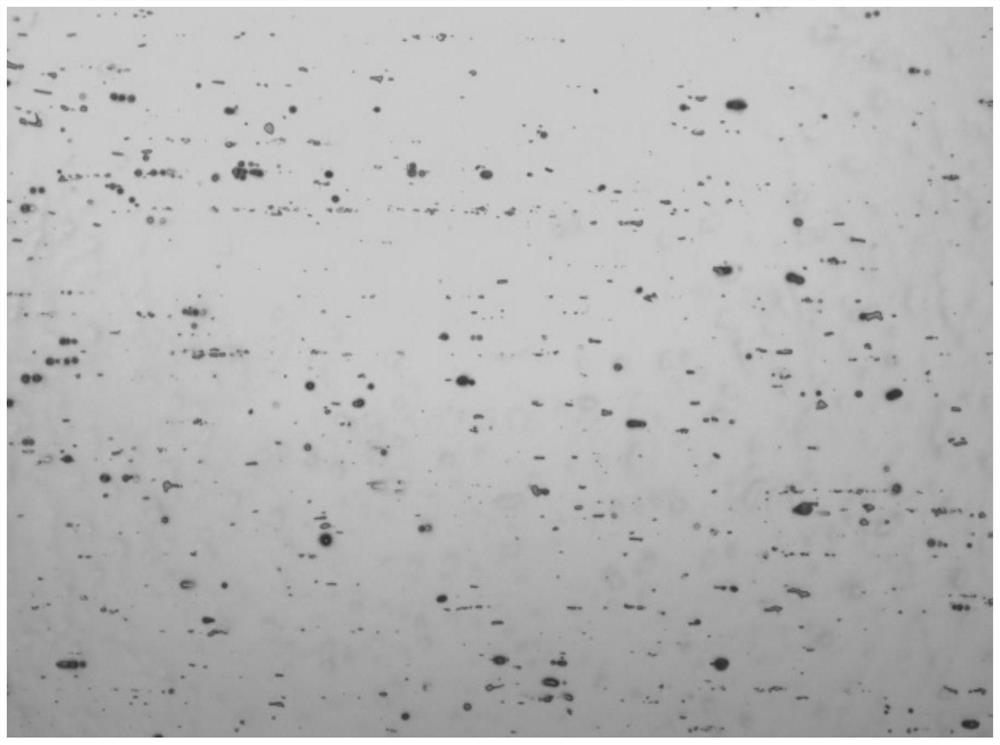

[0023] Specific implementation mode one: combine Figure 1 to Figure 2 Describe this embodiment mode, a kind of manufacturing method of hover furnace production aluminum alloy structural part for vehicle of this embodiment mode, it comprises the following steps:

[0024] Step 1, semi-continuous casting to obtain ingots of aluminum alloy structural parts for vehicles produced by hovering furnaces;

[0025] Step 2, milling the ingots of aluminum alloy structural parts for vehicles produced by the hovering furnace;

[0026] Step 3, heating the ingot after the surface milling of the aluminum alloy structural parts for vehicles produced by the hovering furnace;

[0027] Step 4, hot-rolling the ingots of the aluminum alloy structural parts produced by the hovering furnace for vehicles;

[0028] Step 5, cold-rolling the hot-rolled coils of aluminum alloy structural parts for vehicles produced by the hovering furnace;

[0029] Step 6, quenching the cold-rolled coils of aluminum all...

specific Embodiment approach 2

[0035] Specific implementation mode two: combination Figure 1 to Figure 2 Describe this embodiment. Step 3 of this embodiment is to heat the ingot after milling the aluminum alloy structural parts for vehicles produced by the hovering furnace. Hours, the metal temperature actually reaches 450-460°C. Others are the same as the first embodiment.

specific Embodiment approach 3

[0036] Specific implementation mode three: combination Figure 1 to Figure 2 Describe this embodiment. Step 4 of this embodiment is to heat the ingot of aluminum alloy structural parts for vehicles produced by a hovering furnace and then perform hot rolling. , 274mm, 244mm, 214mm, 184mm, 154mm, 124mm, 99mm, 69mm, 46mm, 28mm, 15mm, 5.8mm, the tolerance range of the thickness is ±0.10mm. Others are the same as those in Embodiment 1 or 2.

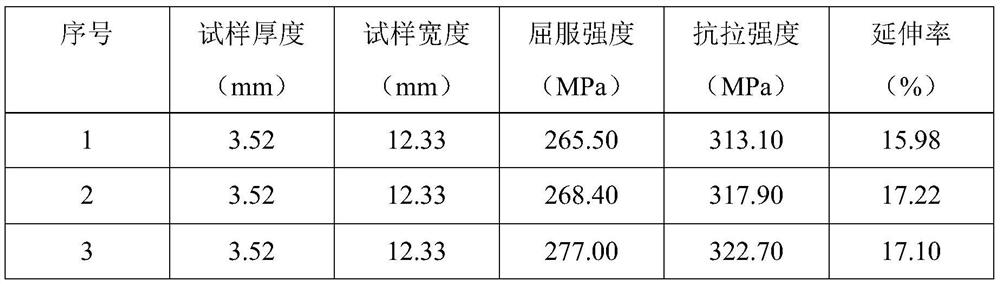

[0037] Specific implementation mode four: combination Figure 1 to Figure 2 To illustrate this embodiment, step 5 of this embodiment is to cold-roll the hot-rolled coils of aluminum alloy structural parts for vehicles produced by the hovering furnace, and the remaining thicknesses after the cold-rolling passes are cut off are 5.8mm, 4.7mm, and 3.9mm in sequence , 3.5mm, the tolerance range of the thickness is ±0.05mm. Others are the same as the specific embodiment 1, 2 or 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com