Short-process continuous preparation method of high-performance copper-chromium alloy wire rod

A copper-chromium-based wire and high-performance technology, which is applied in the field of short-process continuous preparation of high-performance copper-chromium-based alloy wire, can solve the problems of long route, low production efficiency of alloy wire, and many process passes, and achieves increased production. The effect of large cooling intensity, improving production efficiency and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

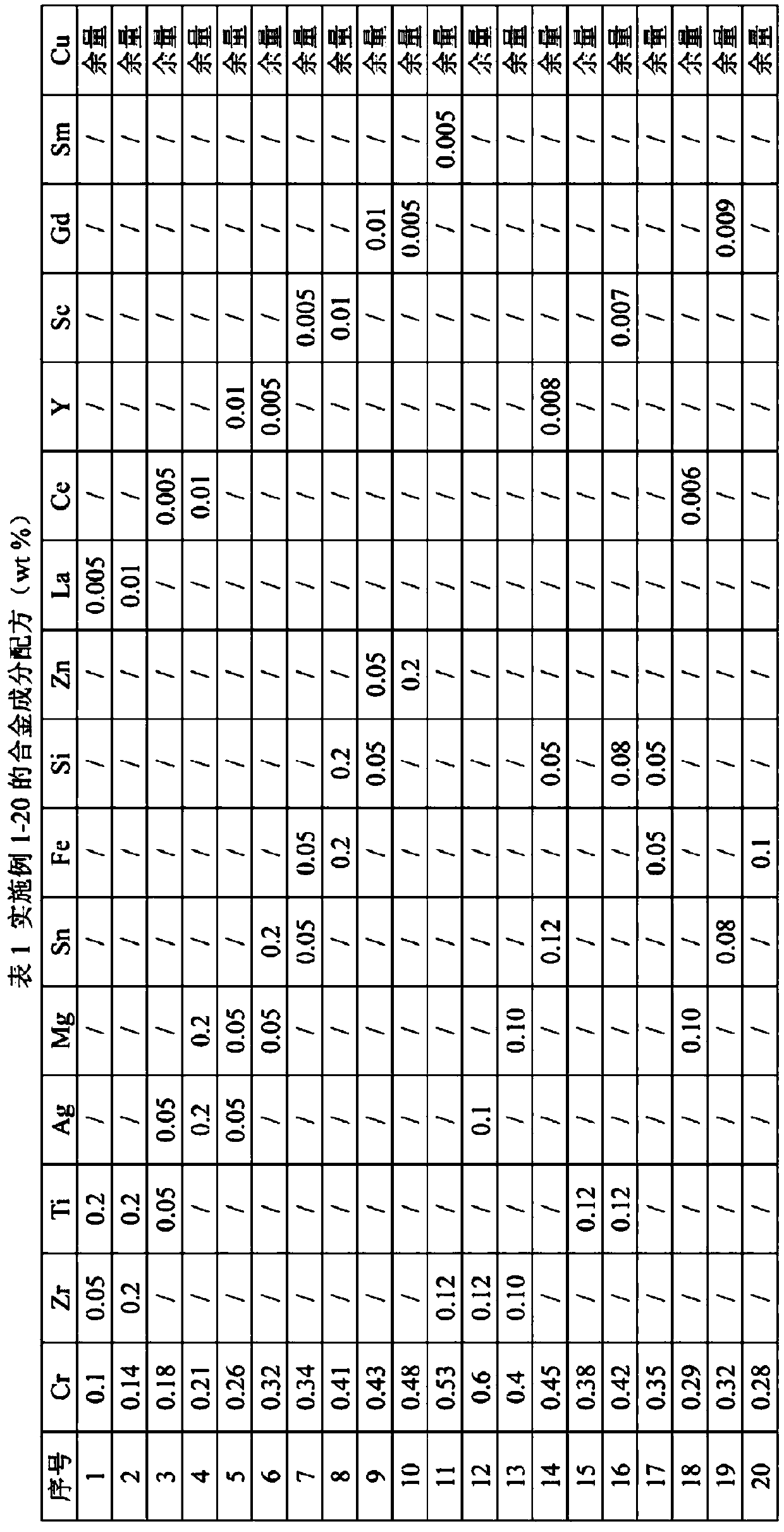

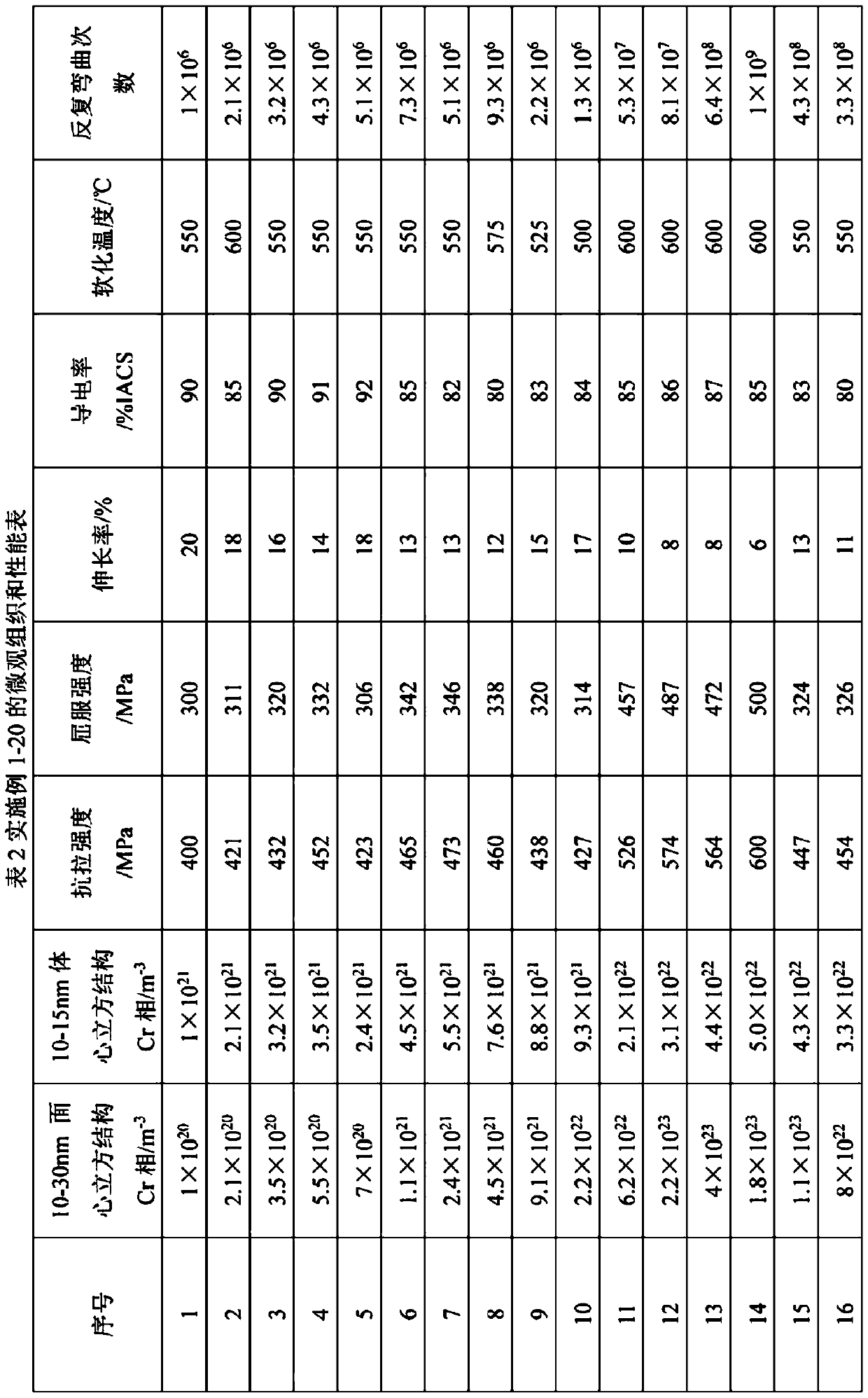

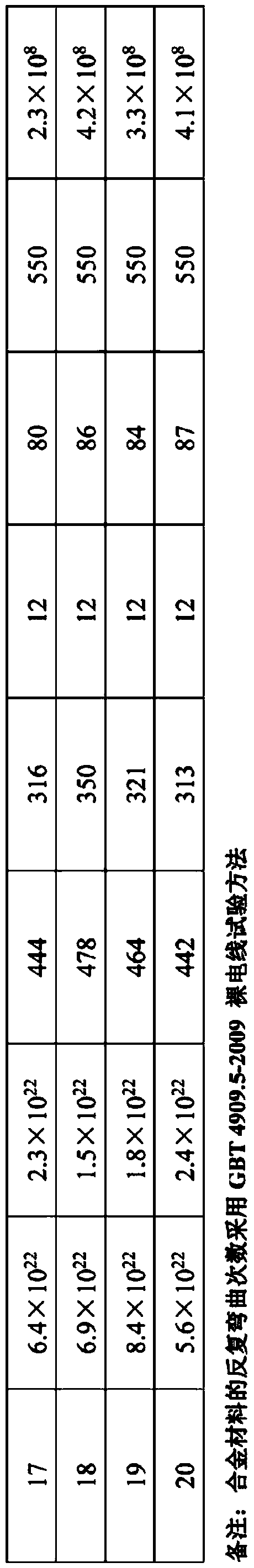

[0021] The alloy of the invention is smelted using the following raw materials: electrolytic copper, pure chromium, copper-zirconium master alloy, sponge titanium and copper-lanthanum master alloy. The composition of the alloy is shown in Example 1 of Table 1.

[0022] 1. Melting and casting: Add electrolytic copper and pure chromium into a non-vacuum power frequency induction furnace. After the above materials are melted, pass high-purity argon for protection, and then add copper-zirconium master alloy, sponge titanium and copper-lanthanum intermediate For the alloy, raise the temperature to 1300°C. After the melt is completely melted, stir evenly. The casting temperature is controlled at 1250°C. After holding for 20 minutes, continuous upward casting is carried out. The pitch is 1mm, the stop time is 0.30s, and the pulling time is is 0.20s, the stop-pull time ratio is 1.5, and the lifting speed is 300mm / min, cast into a copper rod with a diameter of 18mm.

[0023] 2. Contin...

Embodiment 2

[0030] The alloy of the invention is smelted using the following raw materials: electrolytic copper, pure chromium, copper-zirconium master alloy, sponge titanium and copper-lanthanum master alloy. The composition of the alloy is shown in Example 2 of Table 1.

[0031] 1. Melting and casting: Add electrolytic copper and pure chromium into a non-vacuum power frequency induction furnace. After the above materials are melted, pass high-purity argon for protection, and then add copper-zirconium master alloy, sponge titanium and copper-lanthanum intermediate For the alloy, raise the temperature to 1350°C. After the melt is completely melted, stir evenly. The casting temperature is controlled at 1200°C. After 20 minutes of heat preservation, continuous casting is carried out. The pitch is 6mm, the stop time is 0.30s, and the pulling time is is 0.05s, the stop-pull time ratio is 6, and the lifting speed is 600mm / min, cast into a copper rod with a diameter of 20mm.

[0032] 2. Contin...

Embodiment 3

[0039] The alloy of the invention is smelted using the following raw materials: electrolytic copper, pure chromium, pure silver, sponge titanium and copper-cerium master alloy. The composition of the alloy is shown in Example 3 of Table 1.

[0040] 1. Melting and casting: Add electrolytic copper and pure chromium into a non-vacuum power frequency induction furnace. After the above materials are all melted, pass high-purity argon for protection, and then add pure silver, sponge titanium and copper-cerium intermediate alloy. Raise the temperature to 1320°C. After the melt is completely melted, stir evenly. The casting temperature is controlled at 1220°C. After holding for 20 minutes, continuous casting is carried out. The pitch is 3mm, the stop time is 0.15s, and the pulling time is 0.05 s, the stop-pull time ratio is 3, and the upward speed is 400mm / min, cast into a copper rod with a diameter of 18mm.

[0041] 2. Continuous extrusion: The above-mentioned alloy copper rod is su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com