Method using NGO monocrystal substrate to prepare a shaft REBCO high temperature superconductor thick film

A single crystal substrate, high temperature superconducting technology, applied in the usage of superconductor elements, single crystal growth, single crystal growth and other directions, can solve small supersaturation, it is difficult to obtain pure a-axis film growth window, difficult to achieve, etc question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

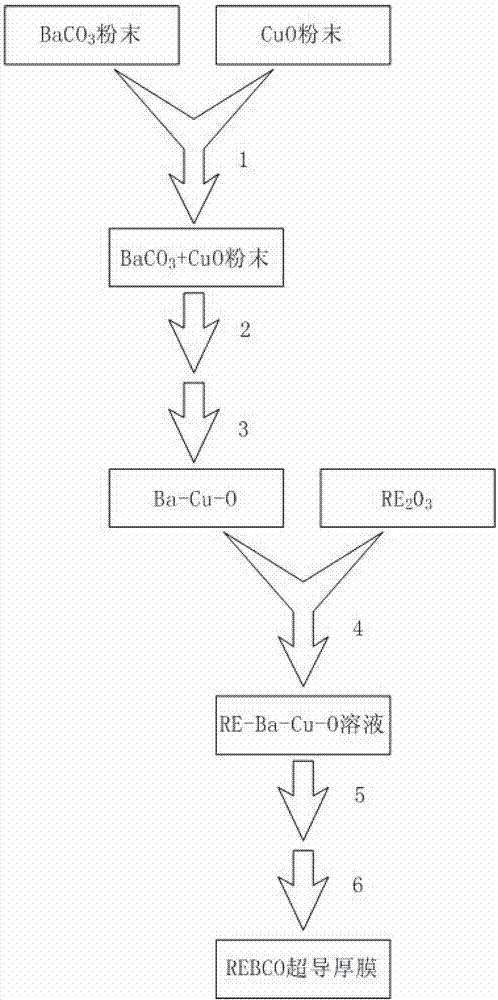

[0033] The method for growing REBCO superconducting thick film by liquid phase epitaxy of the present invention grows YBCO superconducting thick film, and concrete steps are:

[0034] 1. Take BaCO 3 powder and CuO powder for batching to obtain BaCO 3 +CuO powder, BaCO 3 The molar ratio of Ba and Cu in +CuO powder is 0.6.

[0035] Concrete BaCO 3 The amount of powder and CuO powder can be determined according to the YBCO superconducting thick film to be grown, and the BaCO obtained after the batching is completed 3 The molar ratio of Ba and Cu in +CuO powder is 0.6. Among them, BaCO 3 +CuO powder is made of BaCO 3 Powder obtained by mixing powder and CuO powder.

[0036] 2. For the BaCO obtained in step 1 3 +CuO powder for pretreatment, pretreatment includes:

[0037] a. In BaCO 3 + Add absolute ethanol to the CuO powder for wet grinding, and the wet grinding time is set to 3 hours to obtain BaCO 3 +CuO paste.

[0038] b. Dry BaCO 3 +CuO paste.

[0039] 3. Sintering...

Embodiment 2

[0045] The method for growing a REBCO superconducting thick film by liquid phase epitaxy of the present invention grows a SmBCO superconducting thick film, and the specific steps are:

[0046] 1. Take BaCO 3 powder and CuO powder for batching to obtain BaCO 3 +CuO powder, BaCO 3 The molar ratio of Ba and Cu in +CuO powder is 0.6.

[0047] Concrete BaCO 3 The amount of powder and CuO powder can be determined according to the SmBCO superconducting thick film to be grown, and the BaCO obtained after the batching is completed 3 The molar ratio of Ba and Cu in +CuO powder is 0.6. Among them, BaCO 3 +CuO powder is made of BaCO 3 Powder obtained by mixing powder and CuO powder.

[0048] 2. For the BaCO obtained in step 1 3 +CuO powder for pretreatment, pretreatment includes:

[0049] a. In BaCO 3 + Add absolute ethanol to the CuO powder for wet grinding, and the wet grinding time is set to 3 hours to obtain BaCO 3 +CuO paste.

[0050] b. Dry BaCO 3 +CuO paste.

[0051] ...

Embodiment 3

[0056] The method for growing REBCO superconducting thick film by liquid phase epitaxy of the present invention grows YBCO superconducting thick film, and concrete steps are:

[0057] 1. Take BaCO 3 powder and CuO powder for batching to obtain BaCO 3 +CuO powder, BaCO 3 The molar ratio of Ba and Cu in +CuO powder is 0.6.

[0058] Concrete BaCO 3 The amount of powder and CuO powder can be determined according to the YBCO superconducting thick film to be grown, and the BaCO obtained after the batching is completed 3 The molar ratio of Ba and Cu in +CuO powder is 0.6. Among them, BaCO 3 +CuO powder is made of BaCO 3 Powder obtained by mixing powder and CuO powder.

[0059] 2. For the BaCO obtained in step 1 3 +CuO powder for pretreatment, pretreatment includes:

[0060] a. In BaCO 3 +Water was added to CuO powder for wet milling, and the wet milling time was set to 3 hours to obtain BaCO 3 +CuO paste.

[0061] b. Dry BaCO 3 +CuO paste.

[0062] 3. Sintering of pretr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com