Ammonia stripping tail gas treatment method, ammonia-nitrogen wastewater treatment method and equipment

A technology for ammonia nitrogen wastewater and tail gas treatment, which is applied in degassed water/sewage treatment, water/sludge/sewage treatment, separation methods, etc., to achieve the effect of improving the absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

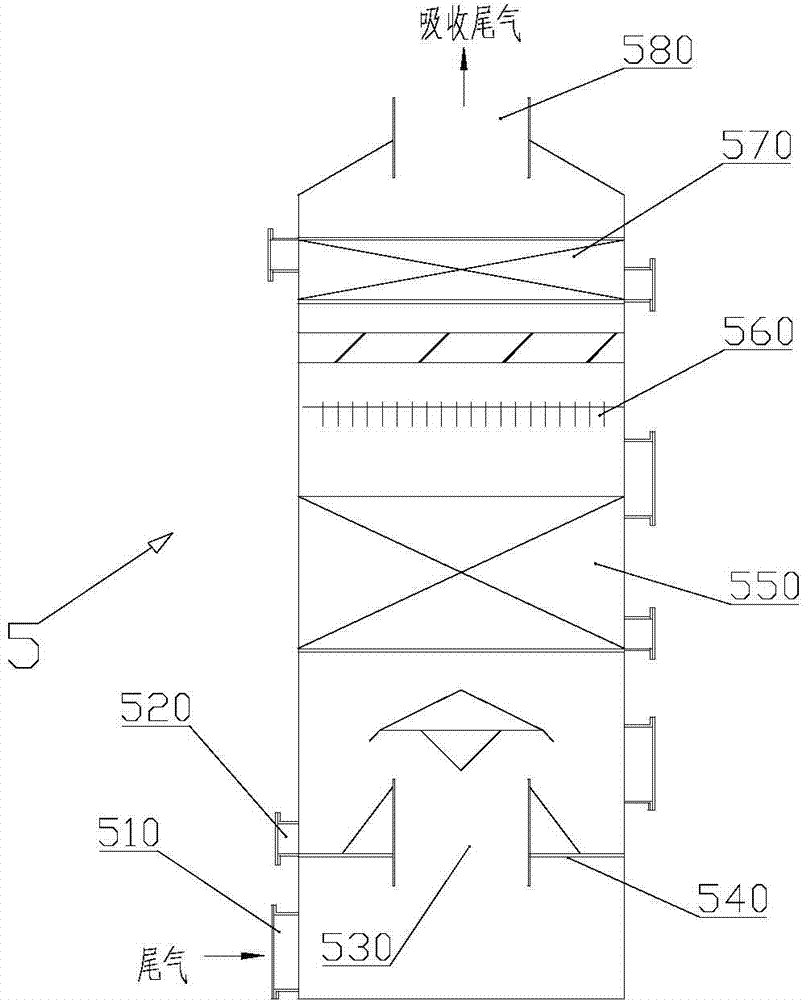

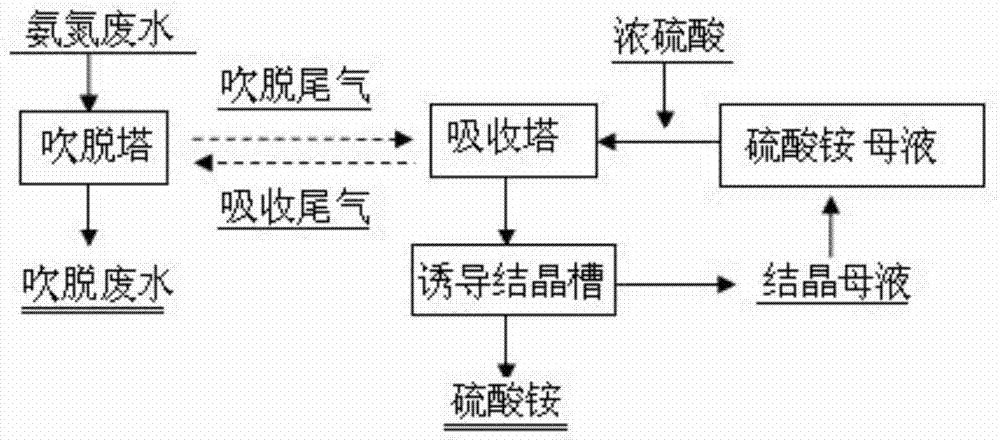

[0051] use as Figure 4 The device shown is processed. The wastewater comes from the ammonium tungstate crystallization mother liquor, and the wastewater flow rate is 8.0m 3 / hour, the concentration of ammonia nitrogen in wastewater is about 7000mg / L.

[0052] Adjust the pH value: adjust the pH value of the wastewater to 12.0 with lime.

[0053] Stripping: During the continuous stripping process of wastewater, the concentration of ammonia nitrogen in the effluent is stable at about 370mg / L, and there is no fouling phenomenon in the stripping tower 5. The absorption tail gas circulates into the stripping tower 5 and replaces air as the stripping gas flow.

[0054] Absorption: The exhaust gas is absorbed by the mixture of 98% concentrated sulfuric acid and ammonium sulfate solution (crystallization mother liquor). The absorption liquid is concentrated sulfuric acid and crystallization mother liquor with a mass volume ratio of 15kg: 1m 3 , the solid content of the crystalliz...

Embodiment 2

[0057] The difference with Example 1 is: when the pH value is adjusted, the pH value of the nitrogen wastewater is adjusted to 10.0; the absorption liquid is concentrated sulfuric acid and the crystallization mother liquor is 8kg by mass volume: 1m 3 The concentrated sulfuric acid concentration is 81%; the seed crystal solid content in the crystallization mother liquor is 60%; the acidity in the crystallization mother liquor is 2mmol / L; the stirring speed in the crystallization step is 30rpm.

Embodiment 3

[0059] The difference with Example 1 is: when the pH value is adjusted, the pH value of the nitrogen wastewater is adjusted to 13.0; the absorption liquid is concentrated sulfuric acid and crystallization mother liquor by mass volume ratio 20kg: 1m 3 The concentrated sulfuric acid concentration is 98%; the seed crystal solid content in the crystallization mother liquor is 20%; the acidity in the crystallization mother liquor is 10mmol / L; the stirring speed in the crystallization step is 60rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com