Temperature Controlled Rolling Process of Magnesium Alloy Coils

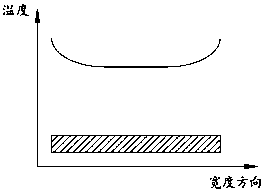

A temperature-controlled rolling, magnesium alloy technology, applied in metal rolling, temperature control and other directions, can solve the problems of non-temperature-controlled rolling, dangerous, difficult to uniformly control the temperature distribution of the roll surface, etc., to improve the plastic deformation ability, The effect of reducing the probability of rolling cracking and excellent secondary forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

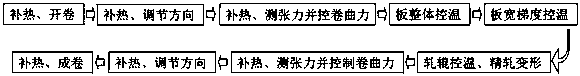

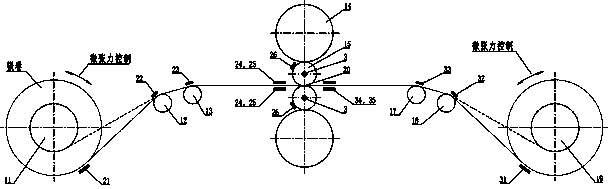

[0082] A single-stand four-high, temperature-controlled rolling process with entry-side and exit-side coilers prepares AZ31 magnesium alloy coils, such as Figure 1a with Figure 1b shown.

[0083] AZ31 magnesium alloy coils produced by conventional technology, with a thickness of 10mm and a width of 500mm;

[0084] 1) Magnesium coils are reheated and uncoiled: the reheating temperature is 250°C, and the uncoiling speed range is 10mm / s;

[0085] 2) Plate heating and direction adjustment: the heating temperature is 250°C, and the adjustable direction range is 0-90°;

[0086] 3) Replenish heat, measure the tension of the sheet and control the curling force: the heating temperature is 250°C, measure the tension of the sheet and feed it back to the uncoiling device to adjust the crimping force, and the tension is controlled within the range of 150±10kN;

[0087] 4) Overall temperature control of the part that is about to bite into the plate: the temperature range is 300°C;

[0...

Embodiment 2

[0096] The embodiment is as described in Example 1, and the difference from Scheme 1 is that the AZ31 magnesium alloy coil produced by the conventional process: the plate thickness is 2mm, and the plate width is 500mm; the process parameters in the experiment are as shown in Example 2 in Attached Table 1 ; After 40 times of rolling, the thickness of the magnesium plate reaches the target thickness of 1 mm, and a high-quality magnesium alloy coil meeting the thickness requirement is obtained.

Embodiment 3

[0098] Embodiment is as described in Example 1, and different from scheme 1, process parameter is as shown in Example 3 in attached table 1 in its experiment; After single-pass rolling, the thickness of magnesium plate reaches target magnesium plate thickness 1mm, Obtain high-quality magnesium alloy coils that meet thickness requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com