Low-carbon high-manganese oriented electrical steel plate, and its manufacturing method

A technology of oriented electrical steel sheet and manufacturing method, applied in the direction of manufacturing tools, metal rolling, temperature control, etc., can solve the problems of many process links, high annealing temperature, high heating temperature, etc., and achieve simple cold rolling process, high yield, The effect of reducing the amount of decarburization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

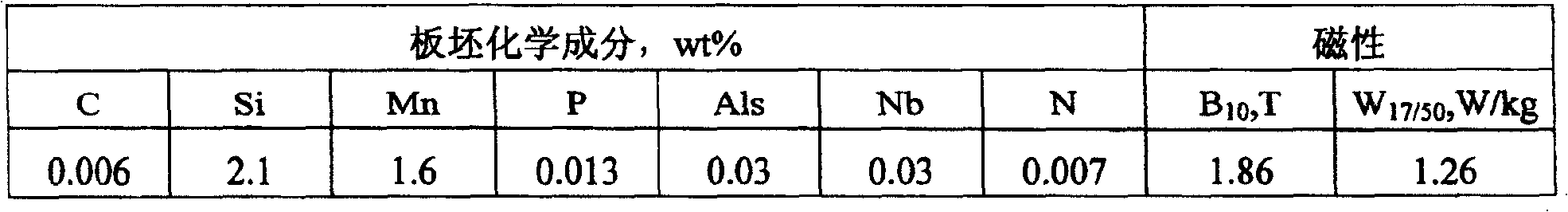

[0024] A kind of manufacture method of example 1 low-carbon high-manganese grain-oriented electrical steel sheet

[0025]A new type of steel slab, the slab thickness is 150-300mm, its chemical composition is, C is 0.006wt%, Si is 2.1wt%, Mn is 1.6wt%, Als is 0.03wt%, Nb is 0.03wt% , N is 0.0070wt%, P is 0.013wt%, the rest is Fe and unavoidable impurities, and the inhibitors are AlN and NbN.

[0026] Heat the slab to 1270°C and keep it warm for 3 hours; then carry out hot rolling, the reduction ratio of the last 3 passes of the hot rolling process is 15%, the final rolling temperature is 860°C, relax for 50 seconds after rolling, and then Carry out rapid cooling, and the cooling rate of rapid cooling is 30 ℃ / second, obtains the hot-rolled strip coil that precipitate and structure are fine and uniform, cancels the normalization annealing of hot-rolled strip coil. Rapid cooling and coiling after hot rolling, the cooling rate of rapid cooling is 10-200°C / s;

[0027] Carry out an...

example 2

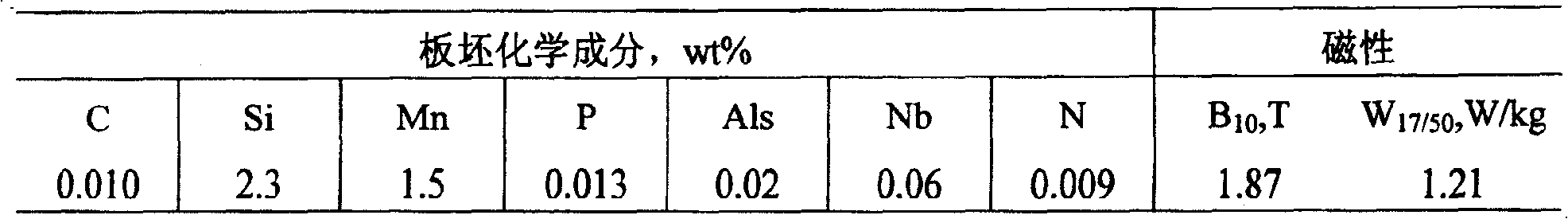

[0032] A kind of manufacture method of example 2 low carbon high manganese grain oriented electrical steel sheet

[0033] A new steel slab with a thickness of 150-300mm, and its chemical composition is: C is 0.010wt%, Si is 2.3wt%, Mn is 1.5wt%, Als is 0.02wt%, Nb is 0.06wt%, N is 0.009wt%, P is 0.013wt%, the rest is Fe and unavoidable impurities, and the inhibitors are AlN, NbC and NbN.

[0034] Heating the slab to 1300°C and keeping it warm for 3 hours; then performing hot rolling, the reduction rate of the last 3 passes of the hot rolling process is 20%, the final rolling temperature is 1000°C, and relaxing for 40 seconds after rolling; then Carry out quick cooling and coiling, the cooling rate of quick cooling is 40 ℃ / second, obtain the hot-rolled coil that precipitate and structure are fine and uniform, cancel the normalized annealing of hot-rolled coil.

[0035] Carry out another cold rolling, the total reduction rate is more than or equal to 82%, and directly roll to t...

example 3

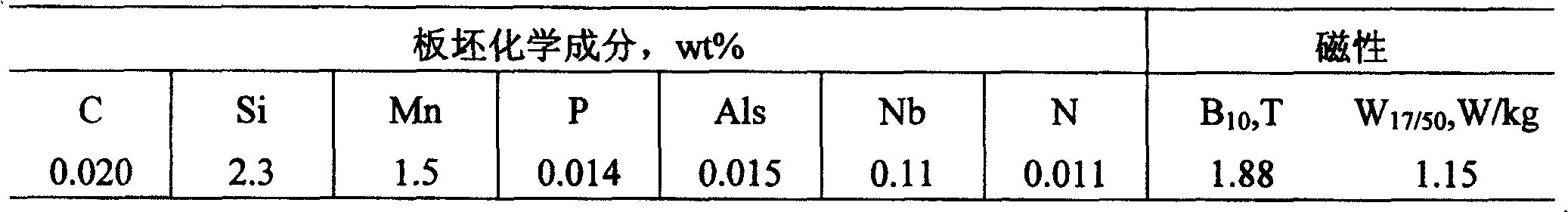

[0040] A kind of manufacture method of example 3 low-carbon high-manganese grain-oriented electrical steel sheets

[0041] A new steel slab with a thickness of 150-300mm, and its chemical composition is: C is 0.020wt%, Si is 2.3wt%, Mn is 1.5wt%, Als is 0.015wt%, Nb is 0.11wt%, N is 0.011wt%, P is 0.014wt%, the rest is Fe and unavoidable impurities, and the inhibitors are AlN and NbC.

[0042] Heat the slab to 1260°C and keep it warm for 3 hours; carry out hot rolling, the reduction rate of the last pass of the hot rolling process is 28%, the final rolling temperature is 980°C, and relax for 45 seconds after rolling; then carry out Rapid cooling and coiling, the cooling rate of rapid cooling is 50°C / s, and the hot-rolled coils with fine and uniform precipitates and structures are obtained, and the normalizing annealing of the hot-rolled coils is cancelled.

[0043] Carry out another cold rolling, the total reduction ratio is ≥ 88%, and directly roll to the final thickness. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com