Thin slab process high magnetic induction oriented electrical steel sheet and its manufacturing method

A high magnetic induction orientation, electrical steel sheet technology, applied in the improvement of process efficiency, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high annealing temperature, high heating temperature, and many process links, and achieve final high temperature annealing. The effect of low temperature, low heating temperature and reasonable chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

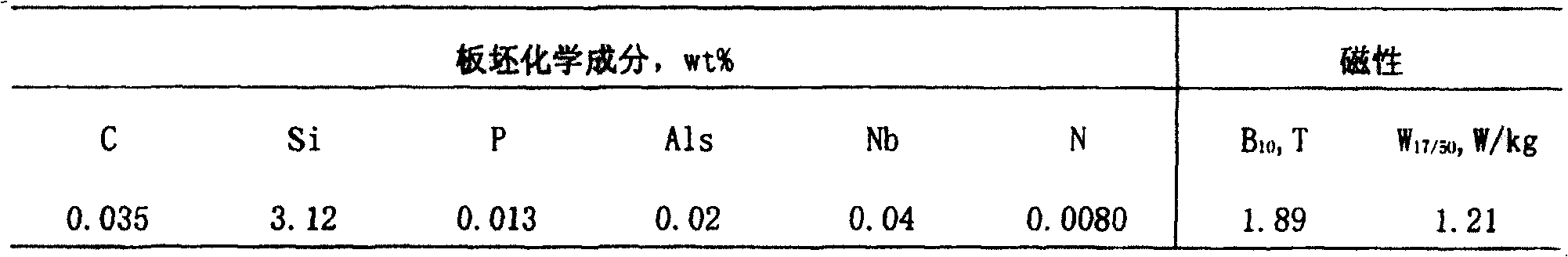

[0022] Example 1 A kind of manufacturing method of thin slab process high magnetic induction oriented electrical steel sheet

[0023] A new type of oriented electrical steel, the thickness of the slab is 60mm, its chemical composition is: C is 0.035wt%, Si is 3.12wt%, Als is 0.02wt%, Nb is 0.04wt%, N is 0.0080wt%, P is 0.013 wt%, and the balance is Fe and unavoidable impurities.

[0024] The casting speed of the slab is 4.5m / min, the superheating degree of the molten steel is 20-30°C, and an electrical steel casting slab with an equiaxed crystal ratio of 55% is obtained. The heat preservation temperature of the electrical steel thin slab is 1190°C, and the heat preservation is 2 hours. Carry out hot rolling again, and the hot rolling is rolled to 2.2mm; The reduction rate of the last 3 passes of the hot rolling process is 15%, the final rolling temperature is 900° C., and the relaxation time after rolling is 40 seconds. Rapid cooling and coiling are then performed at a cooli...

example 2

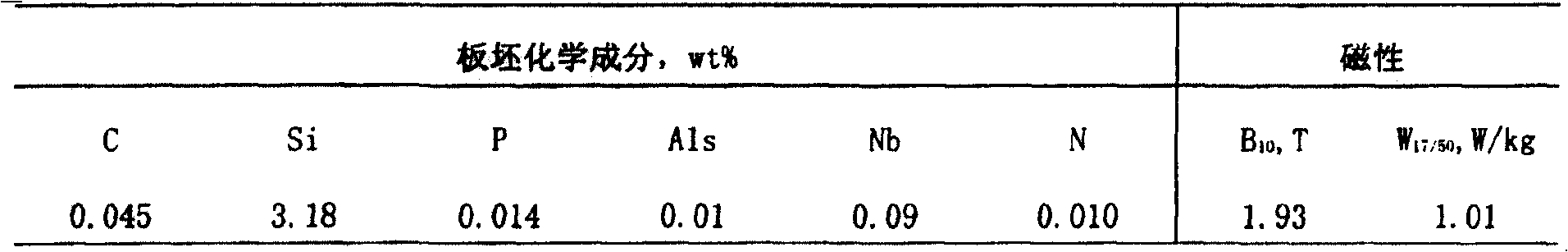

[0031] Example 2 A kind of manufacturing method of thin slab process high magnetic induction oriented electrical steel sheet

[0032] A new type of oriented electrical steel sheet, the slab thickness is 60mm, its chemical composition is: C is 0.045wt%, Si is 3.18wt%, Als is 0.01wt%, Nb is 0.09wt%, N is 0.010wt%, P is 0.014 wt%, and the balance is Fe and unavoidable impurities.

[0033] The slab casting speed is 4.3m / min, the superheated degree of molten steel is 20-30°C, and an electrical steel slab with an equiaxed crystal ratio of 60% is obtained. The heat preservation temperature of the electrical steel thin slab is 1200°C, and the heat preservation is 2 hours. Then hot rolling, rapid cooling and coiling. Hot-rolled to 2.2mm, the reduction ratio of the last two passes of the hot-rolled process is 25%, the final rolling temperature is 950°C, and the relaxation time after rolling is 60 seconds. Rapid cooling is then performed at a cooling rate of 40° C. / sec. To obtain pre...

example 3

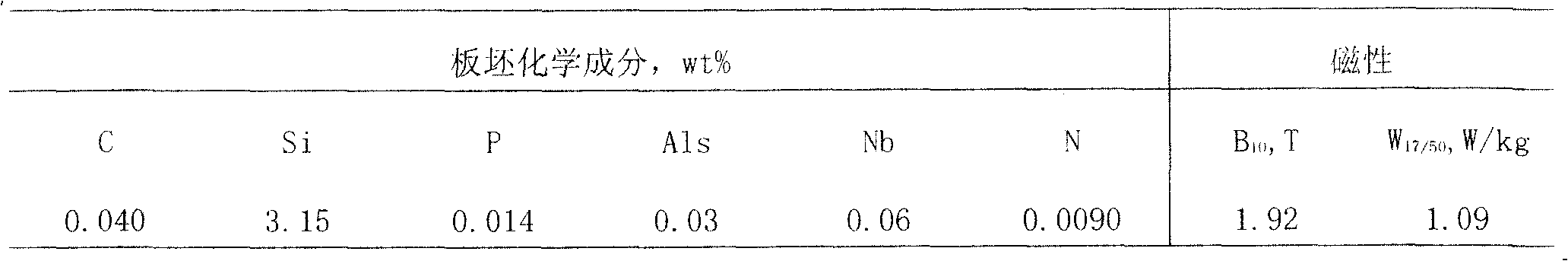

[0040] Example 3 A manufacturing method of thin slab technology high magnetic induction oriented electrical steel sheet

[0041] A new type of oriented electrical steel sheet, the slab thickness is 60mm, its chemical composition is: C is 0.040wt%, Si is 3.15wt%, Als is 0.03wt%, Nb is 0.06wt%, N is 0.0090wt%, P is 0.014 wt%, and the balance is Fe and unavoidable impurities.

[0042] The slab casting speed is 5.0m / min, the superheated degree of molten steel is 20-30°C, and an electrical steel slab with an equiaxed crystal ratio of 65% is obtained. The heat preservation temperature of the electrical steel thin slab is 1210°C, and the heat preservation is 2 hours. Then carry out hot rolling, rapid cooling and coiling; hot rolling to 2.2mm, the reduction rate of the last 3 passes of the hot rolling process is 20%, the final rolling temperature is 930 ° C, and the relaxation time after rolling is 50 seconds. Then perform rapid cooling at a cooling rate of 50° C. / second to obtain f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com