Method of rapid cooling to control magnetic properties of twin-roll strip continuous casting low-silicon non-oriented silicon steel

A twin-roll thin strip continuous casting, oriented silicon steel technology, applied in the field of metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

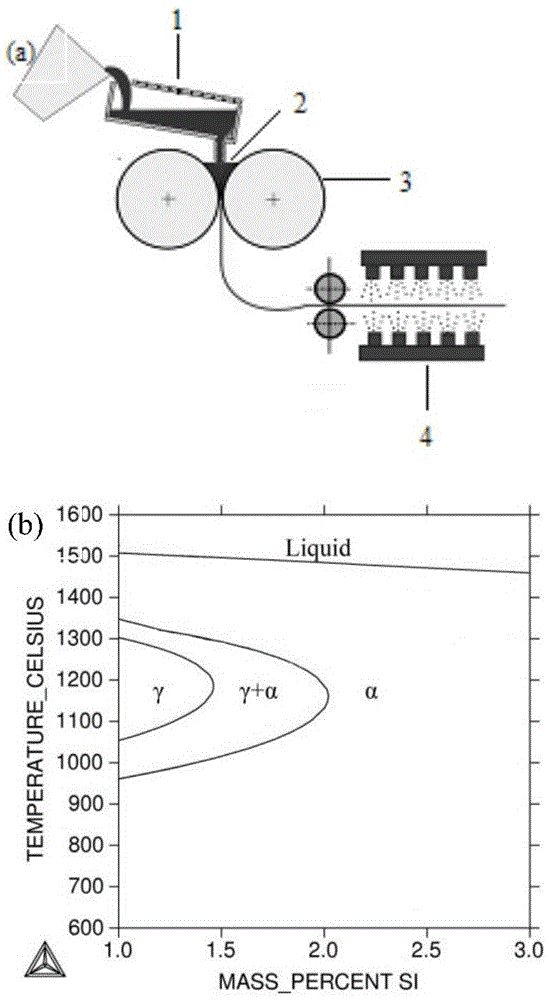

[0025] (1) The chemical composition of low-silicon non-oriented silicon steel is: C: 0.0032%, Si: 1.41%, Mn: 0.35%, Al: 0.21%, O: 0.0043%, S: 0.005%, N: 0.0045%, The rest is Fe and uncontrollable impurities; the non-oriented silicon steel is smelted into molten steel, and the pouring temperature of the molten steel is 1560-1563°C. Composed of steel rollers and side sealing plates, the molten steel solidifies and forms rapidly after contacting the crystallized roller surface of the steel rollers to obtain a cast strip with a thickness of 2.5±0.2mm;

[0026] (2) After the casting strip enters the cooling section, spray water to cool the casting strip, control the starting cooling temperature at 1240-1250°C, the final cooling temperature at 900-910°C, and the cooling rate at 50-60°C / s, and then at 500-510°C ℃ to coil the cast strip; to obtain a cast strip with a coarse and uniform structure;

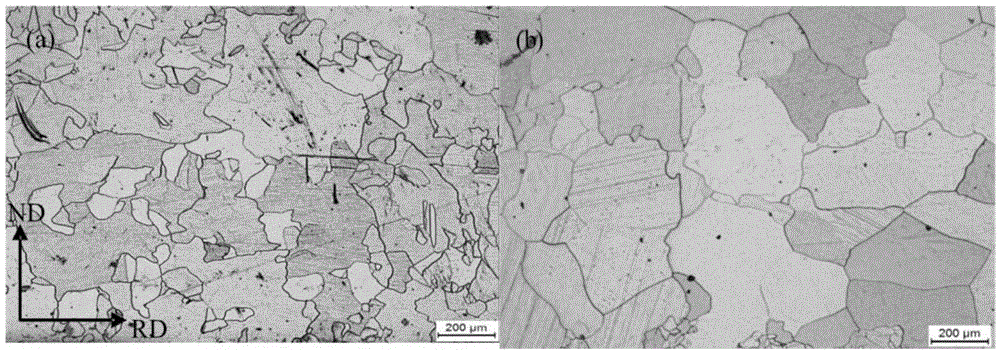

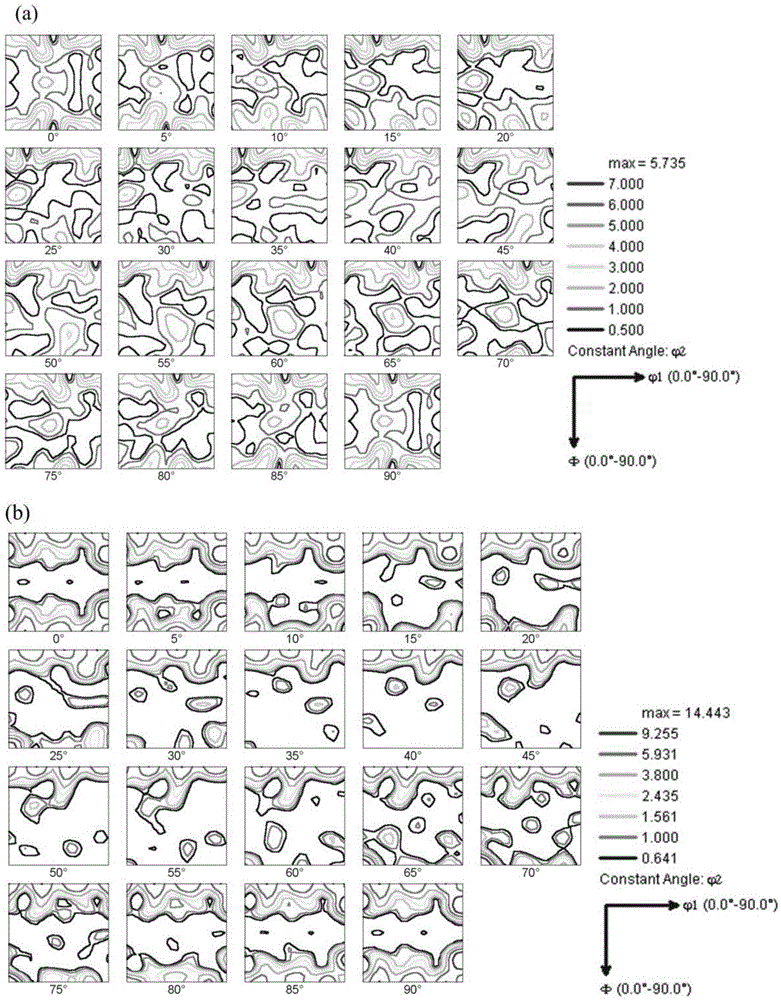

[0027] Depend on figure 2 (a) and image 3 (a) It can be seen that the grain size r...

Embodiment 2

[0034] (1) Low-silicon non-oriented silicon steel according to the mass percentage of chemical composition: C: 0.0034%, Si: 0.80%, Mn: 0.22%, Al: 0.40%, O: 0.0043%, S: 0.005%, N: 0.0045%, the rest It is Fe and uncontrollable impurities; the non-oriented silicon steel is smelted into molten steel, and the pouring temperature of the molten steel is 1578-1582°C. Composed of steel roll and side sealing plate, molten steel solidifies and forms rapidly after contacting the crystallized roll surface of the steel roll, and obtains a cast strip with a thickness of 2.5±0.3mm;

[0035] (2) After the casting strip enters the cooling section, spray water to cool the casting strip, control the starting cooling temperature at 1200-1205°C, the final cooling temperature at 915-920°C, and the cooling rate at 70-100°C / s, and then at 600-605°C ℃ simulated coiling;

[0036] Statistics of grain structure and orientation distribution are shown in Table 2:

[0037] Statistics of cast strip structur...

Embodiment 3

[0042] (1) Low-silicon non-oriented silicon steel according to the mass percentage of chemical composition: C: 0.0028%, Si: 0.42%, Mn: 0.39%, Al: 0.34%, O: 0.0043%, S: 0.005%, N: 0.0045%, the rest It is Fe and uncontrollable impurities; the non-oriented silicon steel is smelted into molten steel, and the pouring temperature is controlled to be about 1600°C. The molten steel is poured into the molten pool of the twin-roll thin strip continuous casting machine through the tundish, and the molten pool is formed by the rotating steel roll. Composed of side sealing plates, the molten steel solidifies and forms rapidly after contacting the crystalline roll surface of the steel roll, and a cast strip with a thickness of 2.5±0.3mm is obtained;

[0043] (2) After the casting strip enters the cooling section, spray water to cool the casting strip, control the starting cooling temperature at 1200-1205°C, the final cooling temperature at 940-945°C, and the water cooling rate at about 80-10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com