A Casting Roll Suitable for Reducing Edge Cracks of Magnesium Alloy Casting and Rolling Sheets

A magnesium alloy and casting roll technology, which is applied in the direction of rolling, metal rolling, metal rolling, etc., can solve problems such as uneven performance division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

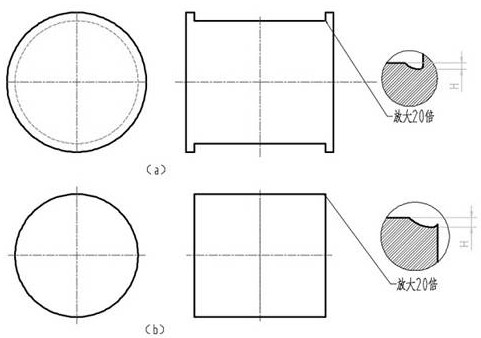

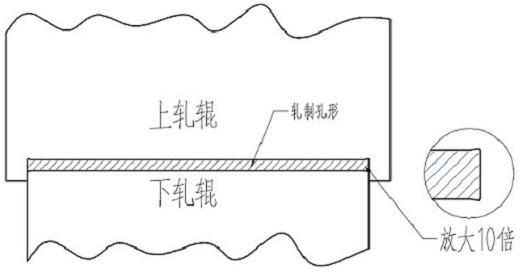

[0015] Take the rolling target size as H ╳ B ╳ L=6mm ╳ 800mm ╳ 500mm as an example: The middle length of the upper roll is L=800mm, the radius R=375mm, the cylinder length at both ends is L=60mm, and the radius is R=395mm; the size of the lower roll Equal to the size of the middle part of the upper roll: length L=800mm, radius R=375mm; According to the design of the present invention, the upper and lower rolls are arranged first, and the height of the middle rolling hole is 6mm, so the groove depth of the arc surface of the upper and lower rolls is 0.6 mm, when the initial molten magnesium alloy has just solidified, it starts to contact with the roll, firstly, it is pressed down in the thickness direction, and then due to the rolling deformation and widening tendency, the edge and the inner end surfaces of the upper roll are rubbed. Normal casting and rolling increases the effective contact area between the edge of the rolled piece and the roll, thus reducing the wear rate and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com