Patents

Literature

34results about How to "Lower friction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

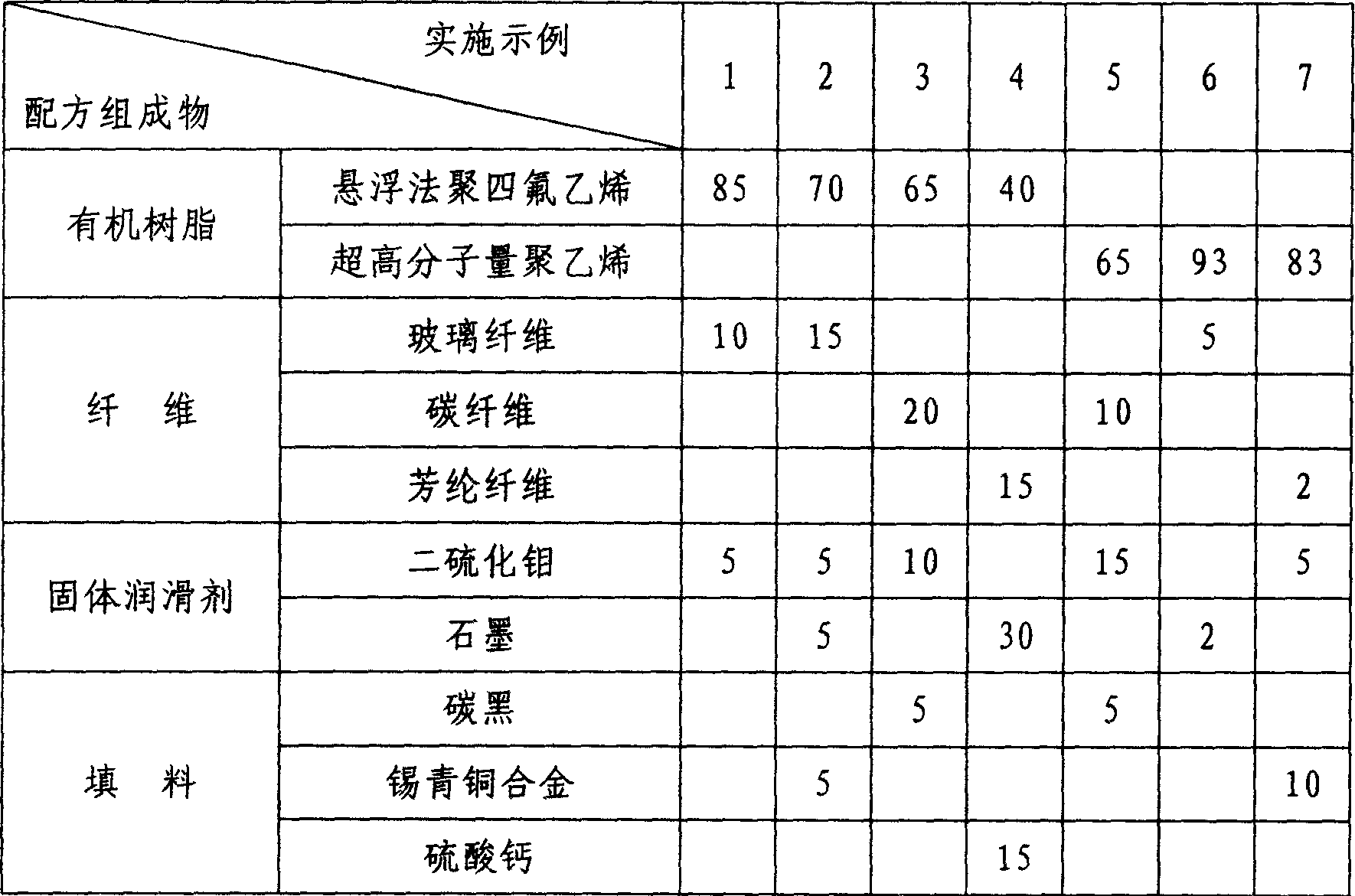

Bridge bearing gliding material and method for preparing the same

ActiveCN1884362AReduce coefficient of frictionImprove wear resistanceBridge structural detailsBridge materialsFiberPolyresin

The invention discloses a bridge support sliding material, which is prepared through following steps: mixing organic resin, fiber, solid lubricant and filler, stirring, pressing and sintering; the weight content of organic resin is 35-99.8%, solid lubricant is 0.1-30%, fiber is 0.1-20%, filler is 0-15%; the organic resin employs politef or super molecular weight polyethylene as resin basic material. The material is characterized by good self-lubricating property and abradability, large bearing capacity, which is two to three times of that of pure PTFE, good creep resistance, low production cost, and wide usage as support bearing for high speed Railway Bridge.

Owner:COB PRECISION PARTS

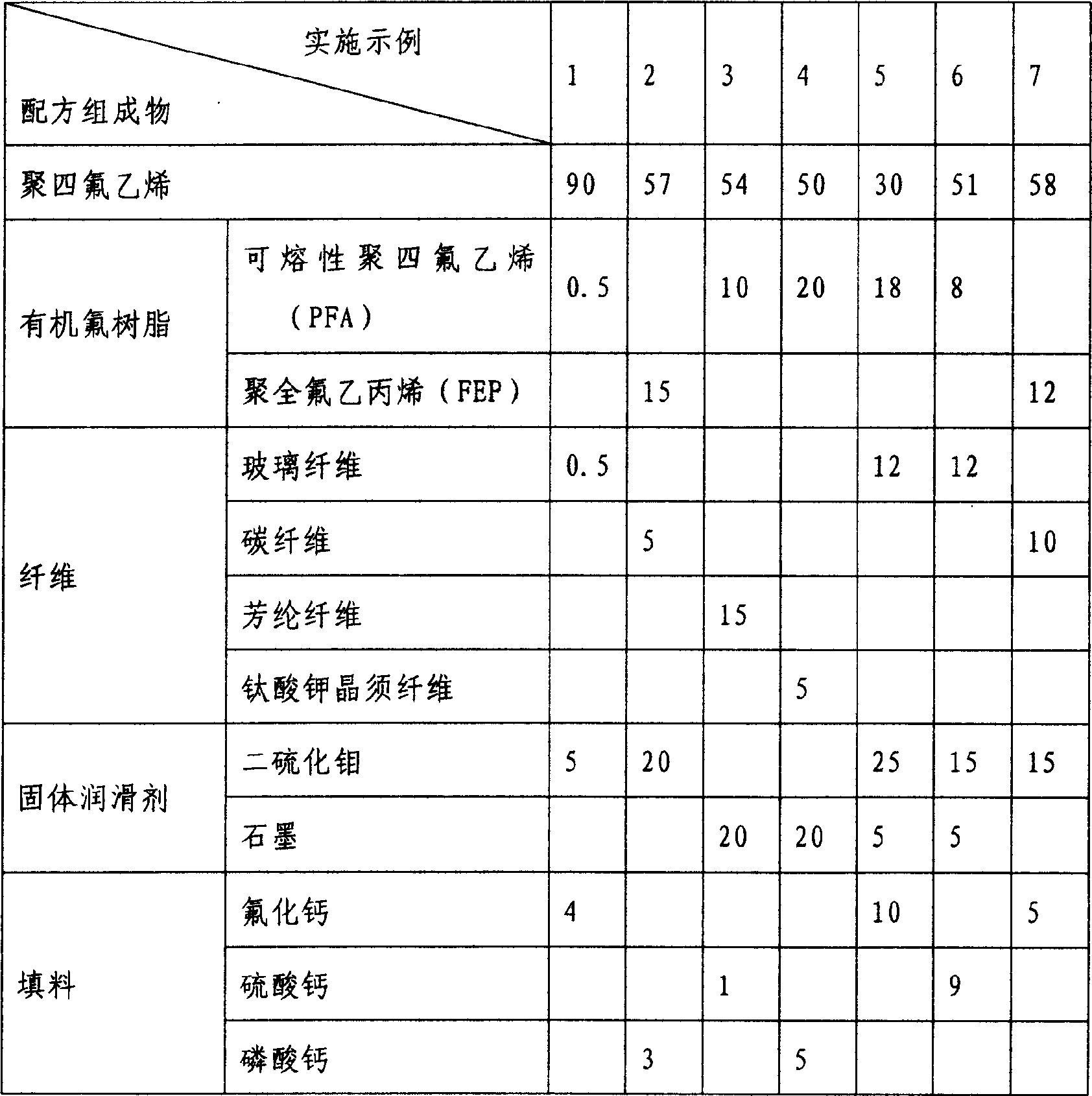

Multilayered self-lubricating material with high porosity and preparation method thereof

ActiveCN1884865AGood dimensional stabilityImprove wear resistanceBearing componentsSuperimposed coating processPorosityMechanical property

The invention relates to a multilayer composite self-lubricant material with high porous degree, wherein the invention uses low-carbon steel sheet as base material; plates copper on the surface; sinters copper alloy powder on the surface of liner layer; and coats sintered polymer on the surface to be rolled and adjusted with thickness. The tin content of copper alloy powder is 1-15%; the optimized valve is 8-12%; the zinc content is 0-6%; the lead content is 0-6%; the optimized valve is 3-5%. The invention has high mechanical property, which can keep the load ability and mechanical strength of liner metallic material, better self-lubricant and anti-abrasion property, with high producing efficiency and low cost.

Owner:COB PRECISION PARTS

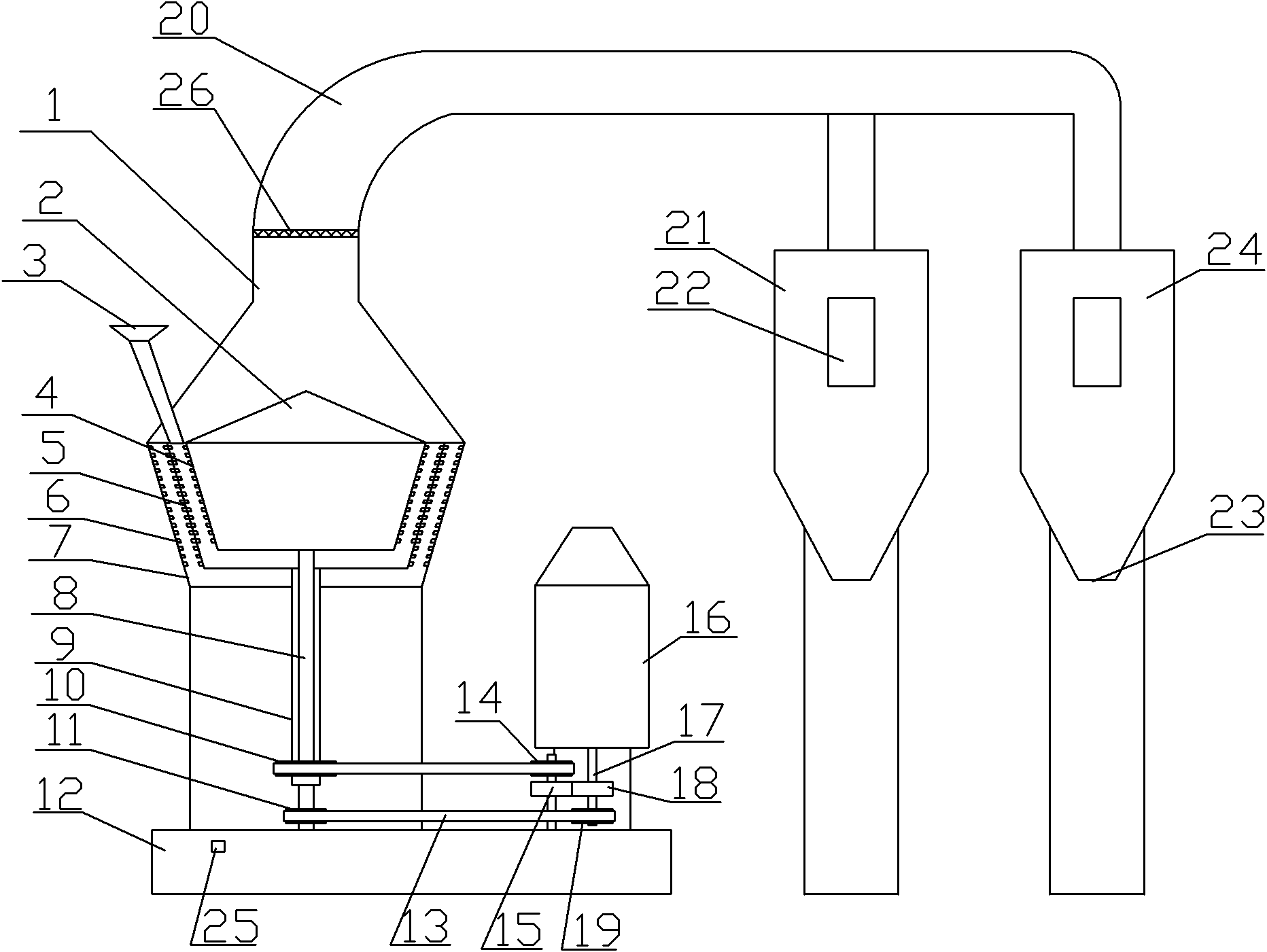

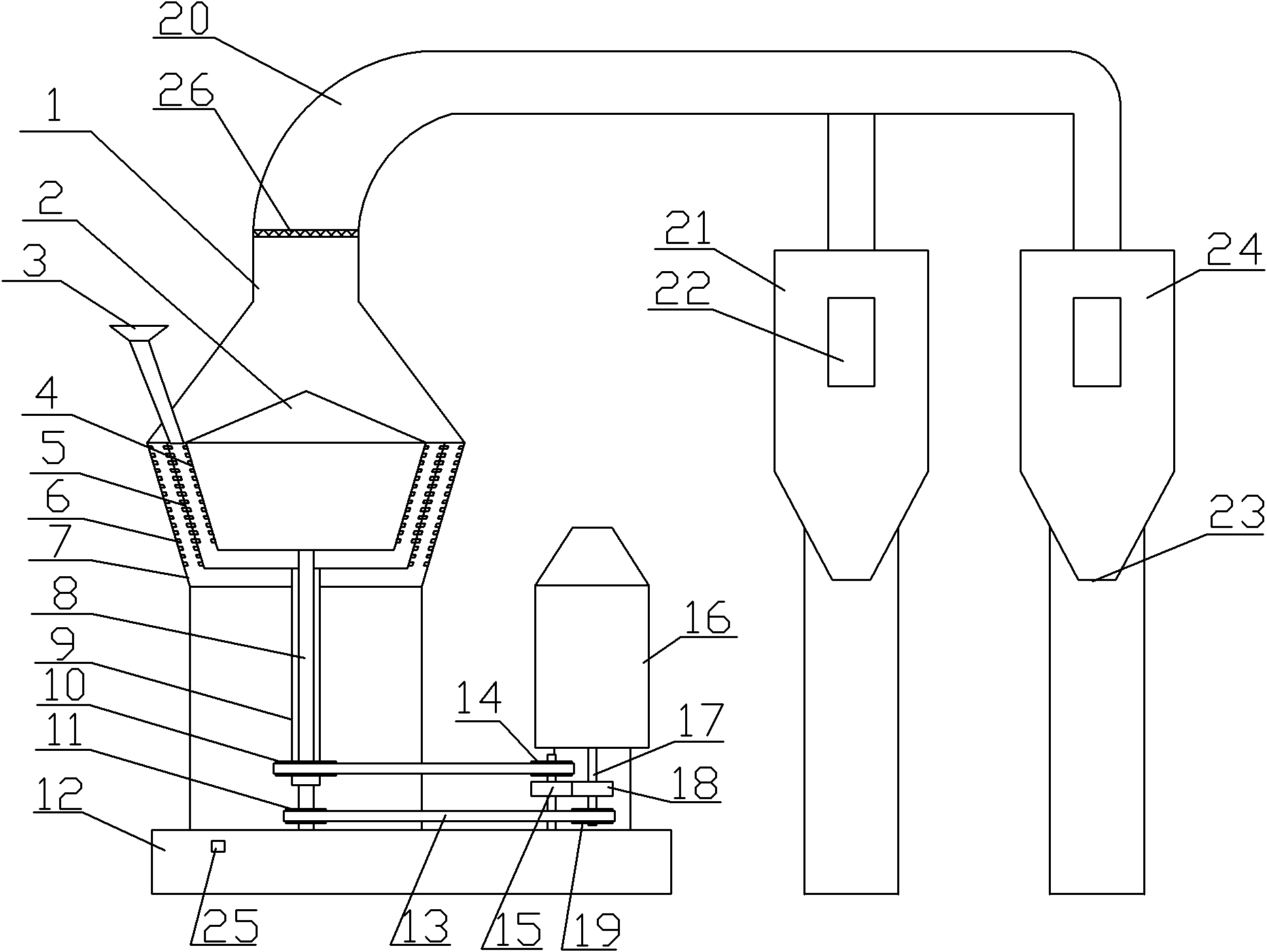

High-shear ultra-fine pulverizing machine

The invention discloses a high-shear ultra-fine pulverizing machine, belonging to pulverizing machines. The high-shear ultra-fine pulverizing machine comprises a material collecting barrel, a delivery pipe and a storage bin, wherein the material collecting barrel is arranged at the upper part of a stand, and the top of the material collecting barrel is provided with a mesh screen; the material collecting barrel comprises a first rotor, a second rotor and a fixed outer bin, the outer side wall of the first rotor, both sides of the second rotor and the inner side of the fixed outer bin are respectively provided with a stator, and the first rotor and the second rotor are connected with a motor arranged on the stand through a transmission mechanism; a power source is arranged on the stand; the material collecting barrel is provided with a material inlet, and the upper part of the material collecting barrel is communicated with the storage bin through the delivery pipe; the bottom of the storage bin is provided with a material outlet, and the side wall of the storage bin is provided with a decompression ventilation window. Compared with the prior art, the high-shear ultra-fine pulverizing machine has the characteristics of increasing working efficiency, quickly shearing a material, reducing friction times and friction time, reducing denaturation produced on the material, and the like, thereby having good popularization and application value.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

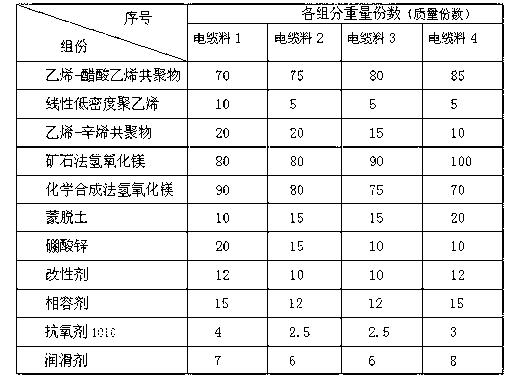

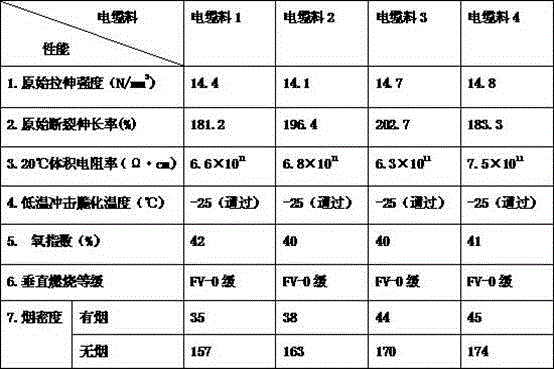

Production method of high-inflaming-retarding low-smoke halogen-free cable material

InactiveCN102993549AIncrease filling volumeImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesChemical synthesisLinear low-density polyethylene

The invention provides a production method of a high-inflaming-retarding low-smoke halogen-free cable material, belongs to the technical field of cable production, and particularly belongs to the technical field of low-smoke halogen-free cable material production. The production method comprises the steps of uniformly mixing linear low-density polyethylene powder with a silane coupling agent to form a modifying agent; agitating the modifying agent, ore-method magnesium hydroxide, chemical synthesis method magnesium hydroxide, montmorillonoid and zinc borate in a mixer for 10-25 minutes and activating the surfaces of the magnesium hydroxide, the montmorillonoid and the zinc borate; adding an ethylene-vinyl acetate copolymer, linear low density polyethylene, an ethylene-octylene copolymer, a compatilizer, an antioxidant and a lubricating agent into the obtained mixture; and granulating with a double-screw-rod extruder. The production method disclosed by the invention is simple in process and is convenient to produce; the oxygen index of the produced cable material is high and is more than 40; the fireproof property is excellent; and a vertical combustion grade experiment reaches the highest grade, FV-0 grade, and the smoke density is lower than that of the other like products.

Owner:扬州丽薇化学科技有限公司

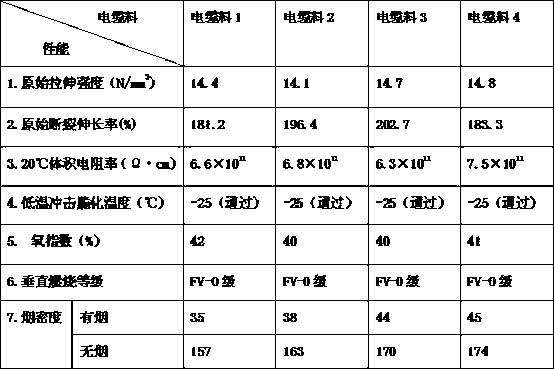

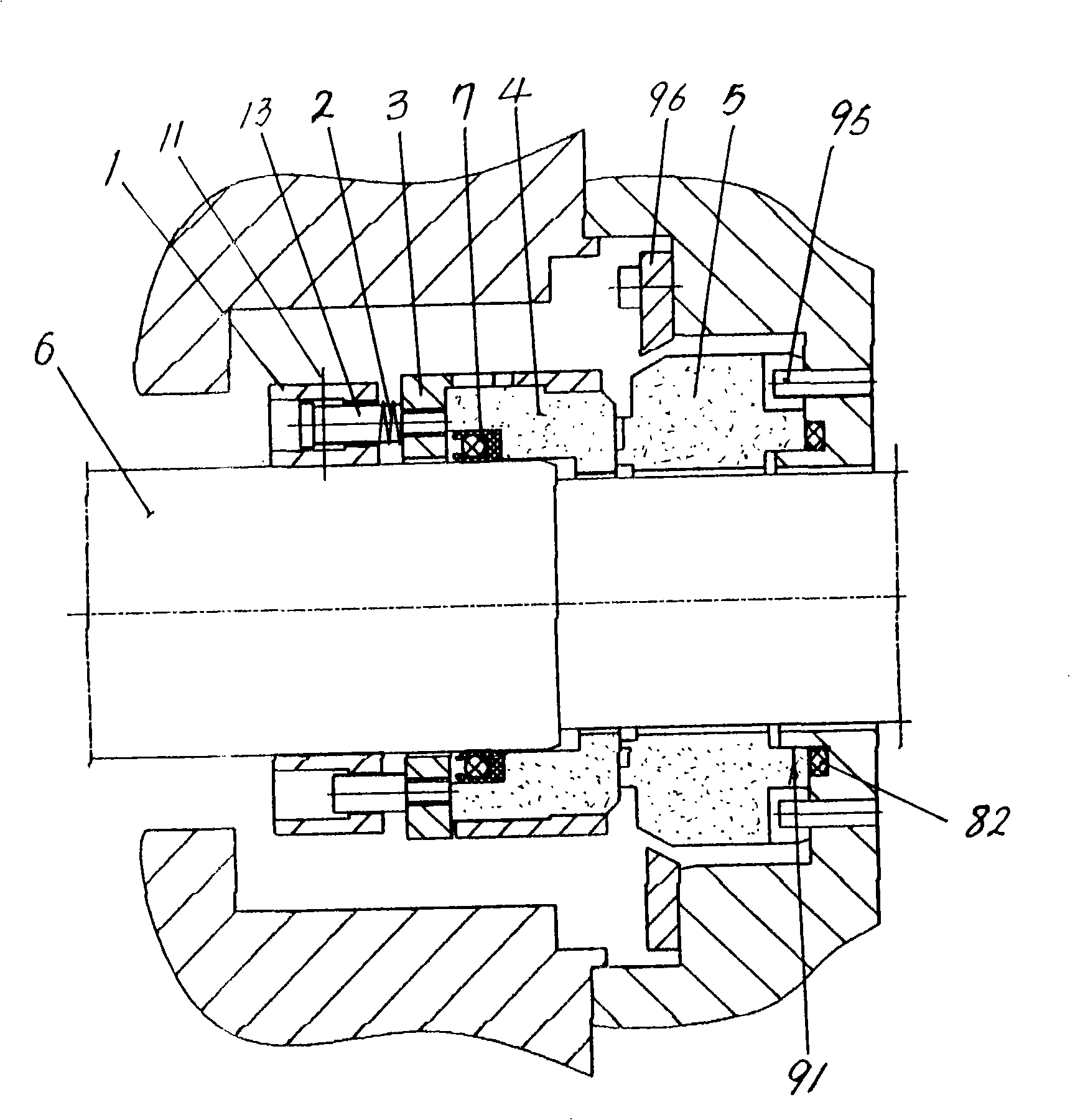

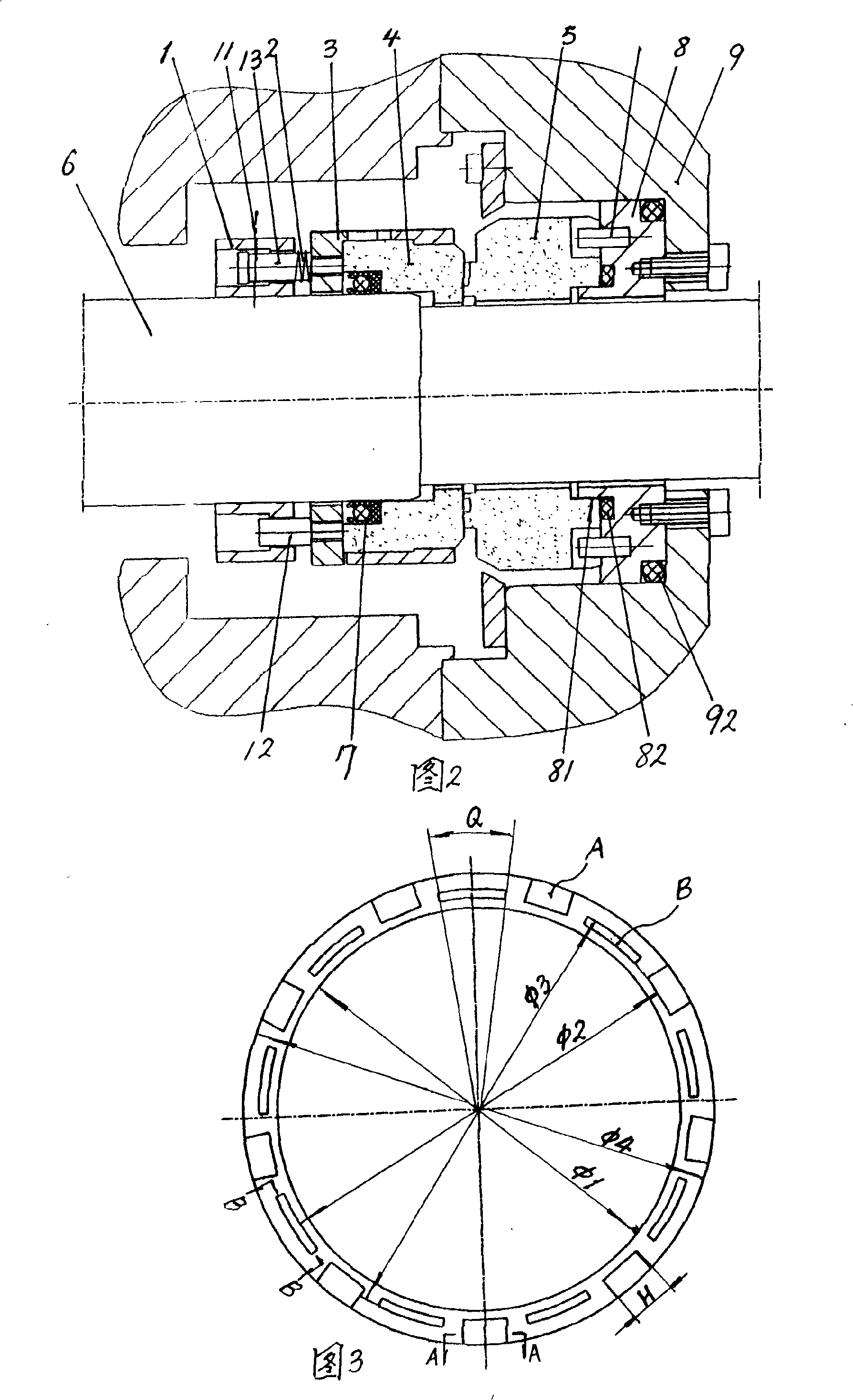

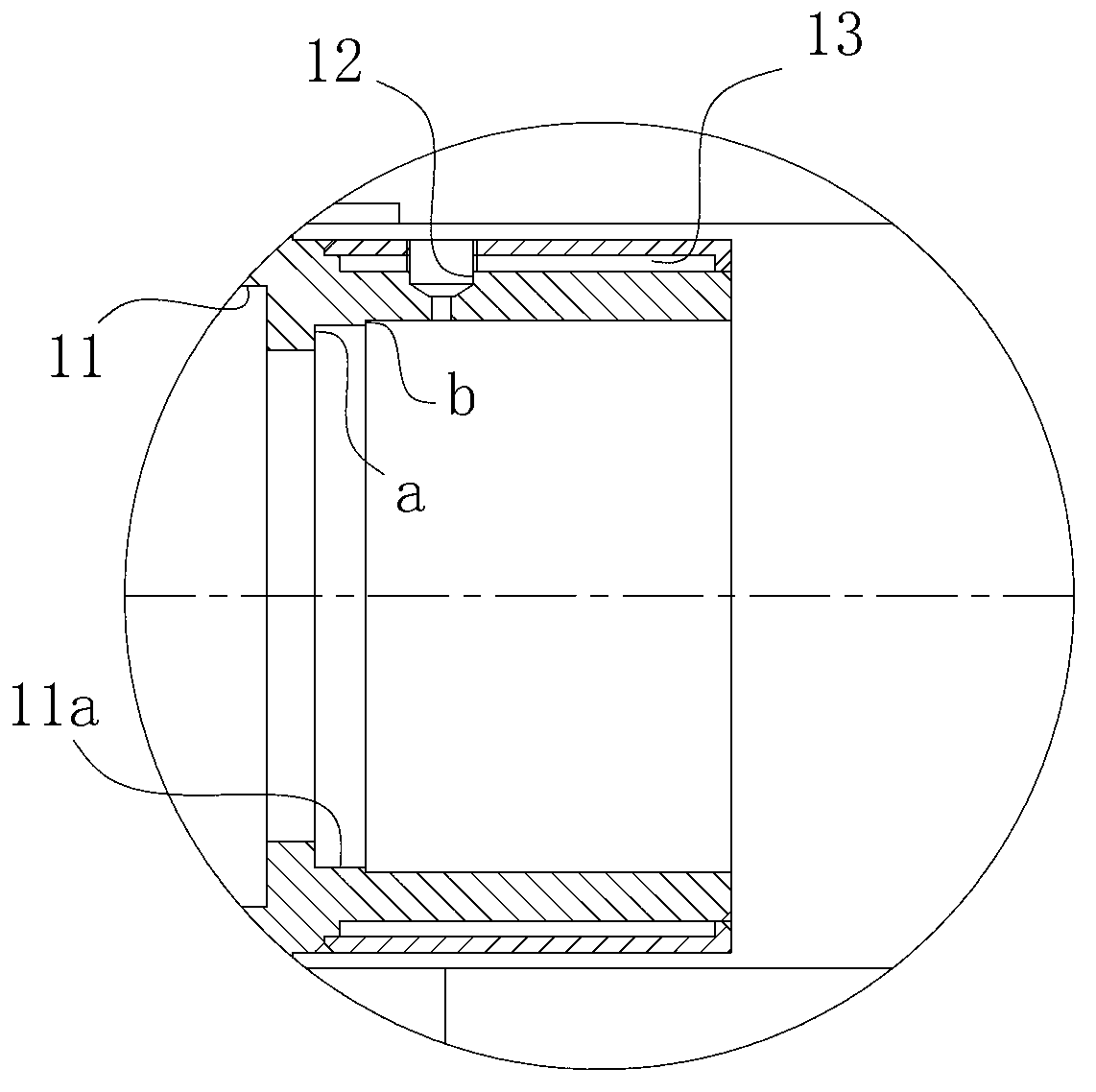

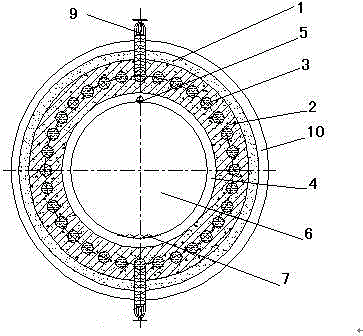

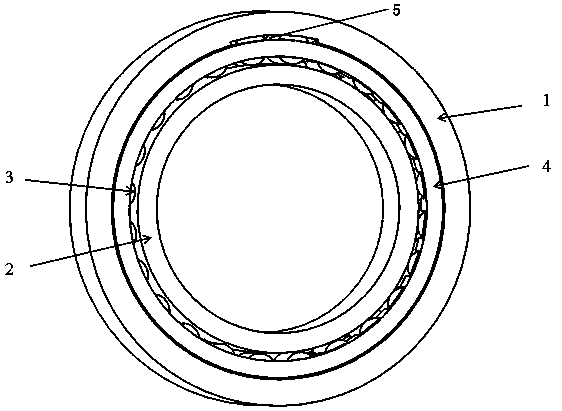

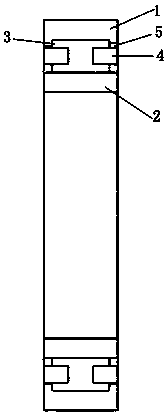

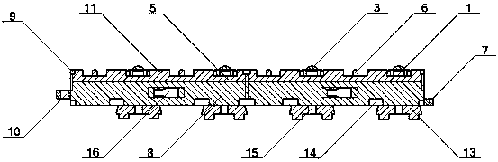

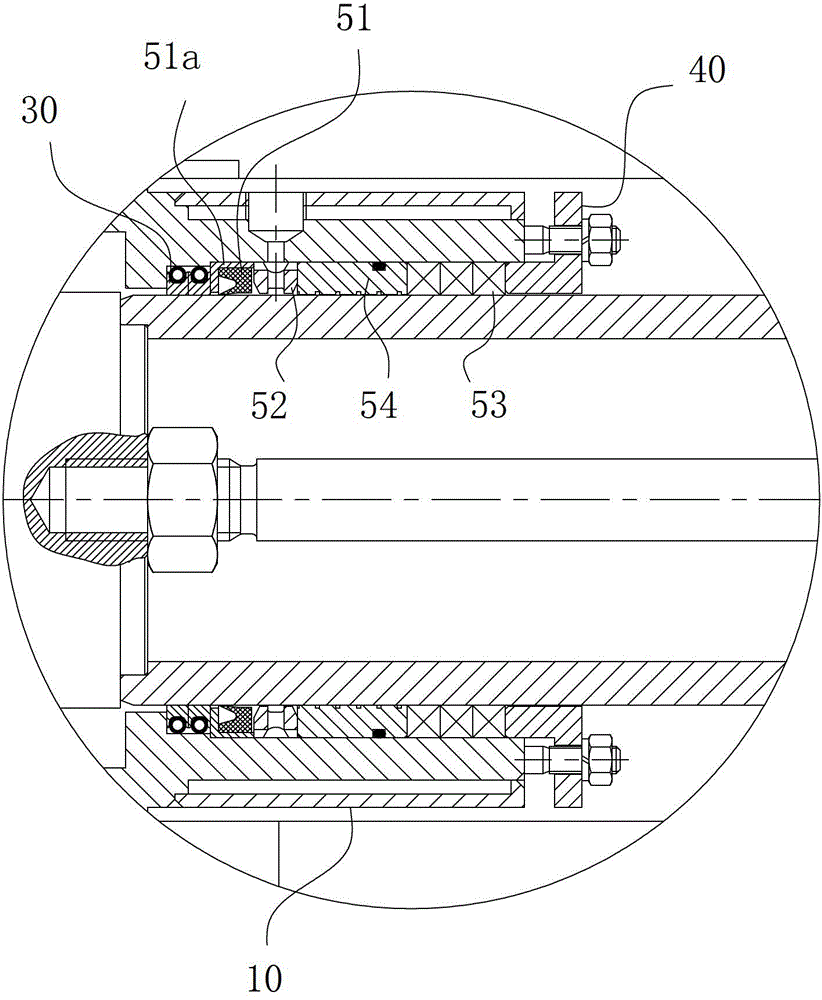

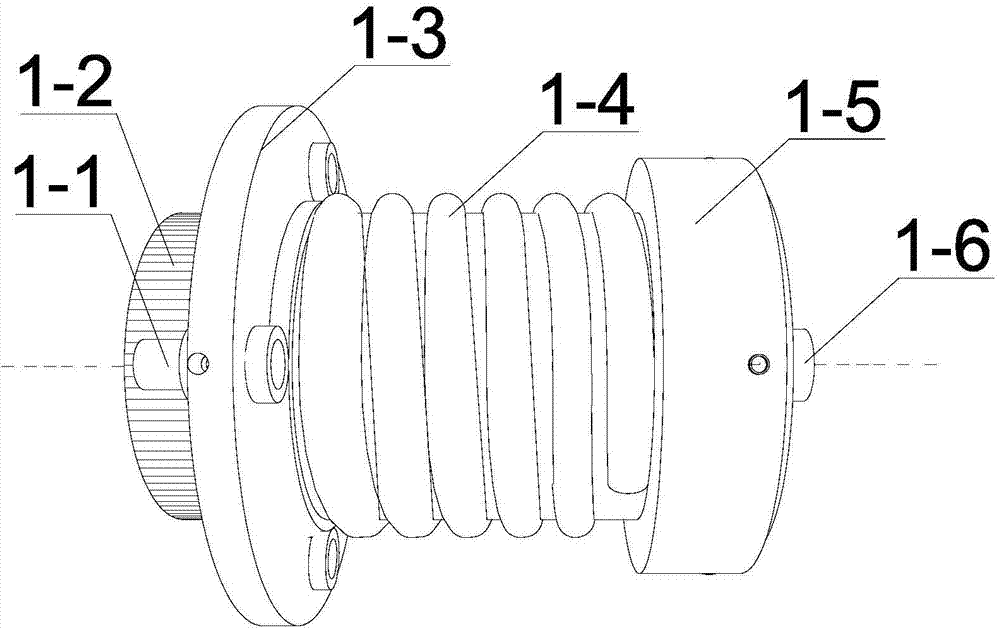

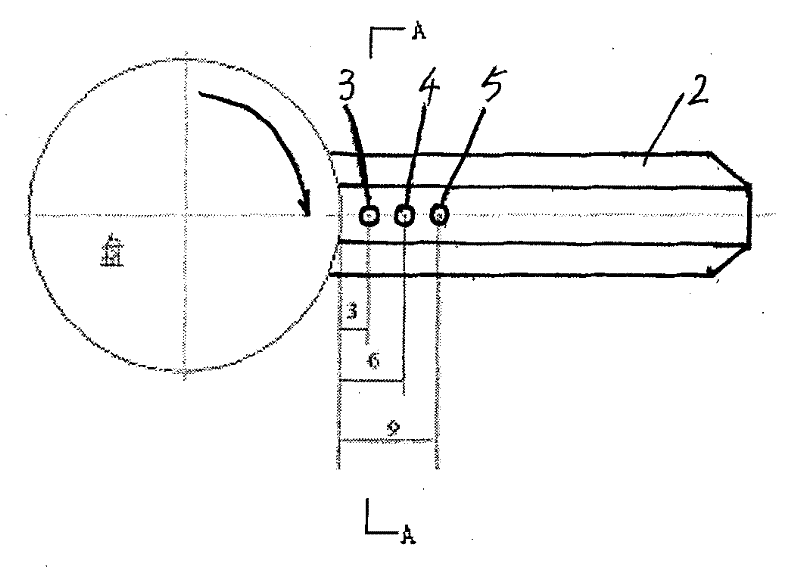

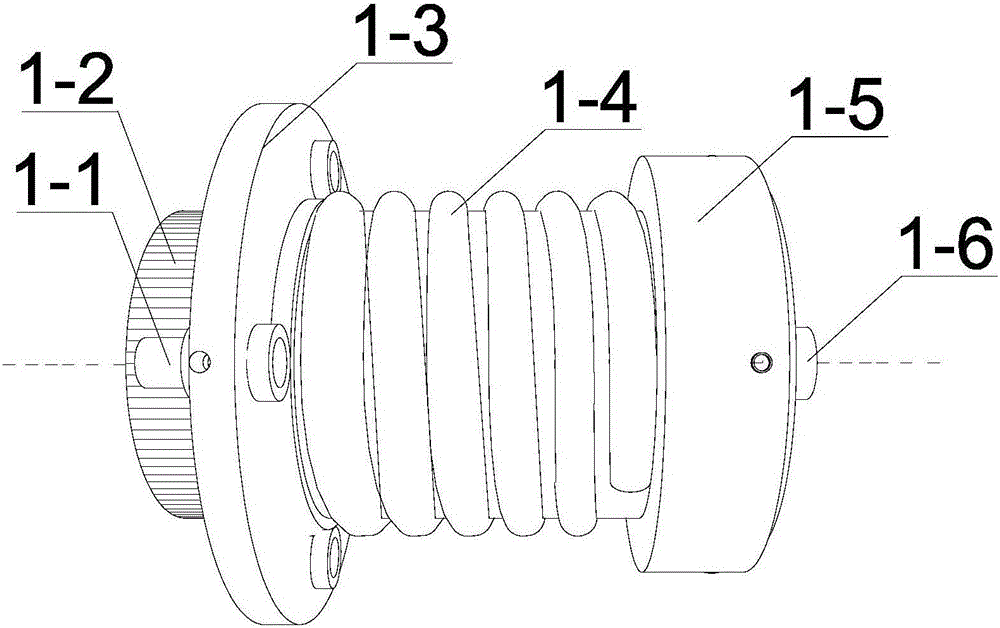

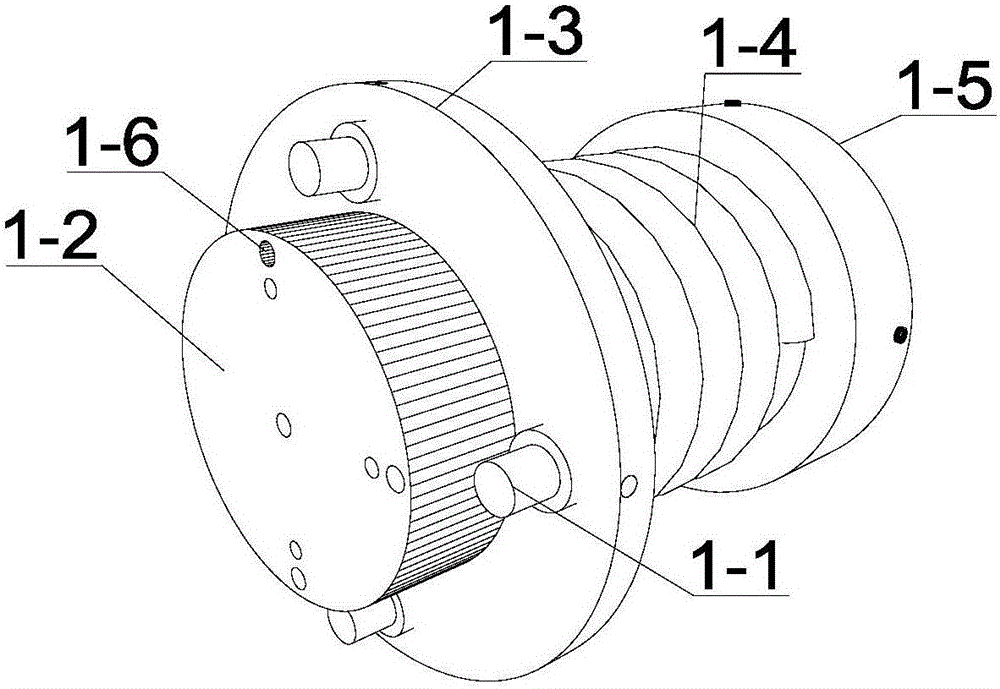

High pressure resistant spring type mechanical sealing device

ActiveCN101493145AEasy to processGood dynamic pressure effect and countercurrent pumping effectEngine sealsEngineeringRubber ring

The invention relates to a high pressure resistant spring type mechanical sealing device which comprises a spring case (1), a spring (2), a thrust ring (3), a kinetic friction ring (4) and a static friction ring (5), wherein, the kinetic friction ring (4) is a compensation ring. The device is characterized in that a slip sealing ring (7) is formed by a tetrafluoroethylene sleeve with a U-shaped cross section and an O-shaped rubber ring embedded inside the tetrafluoroethylene sleeve; the end surface of the kinetic friction ring is distributed with two arch kinetic pressure groove groups that are an open type groove (A) and a closed type groove (B), the static friction ring (5) is installed in a way of being matched with the inner circle of a limiting slot platform on a gland bush (9) or a stationary seat (8), and an O-shaped auxiliary sealing ring is arranged on the vertical end surface of the limiting slot platform. The device has simple structure, simple and convenient processing, good stability and reliability of end surface sealing and auxiliary sealing, and high pressure resistance, can adapt to higher working pressure, works normally under the working condition of 18MP, and ensures leak tightness, little abrasion of the friction end surface and long service life.

Owner:DANDONG COLOSSUS GROUP

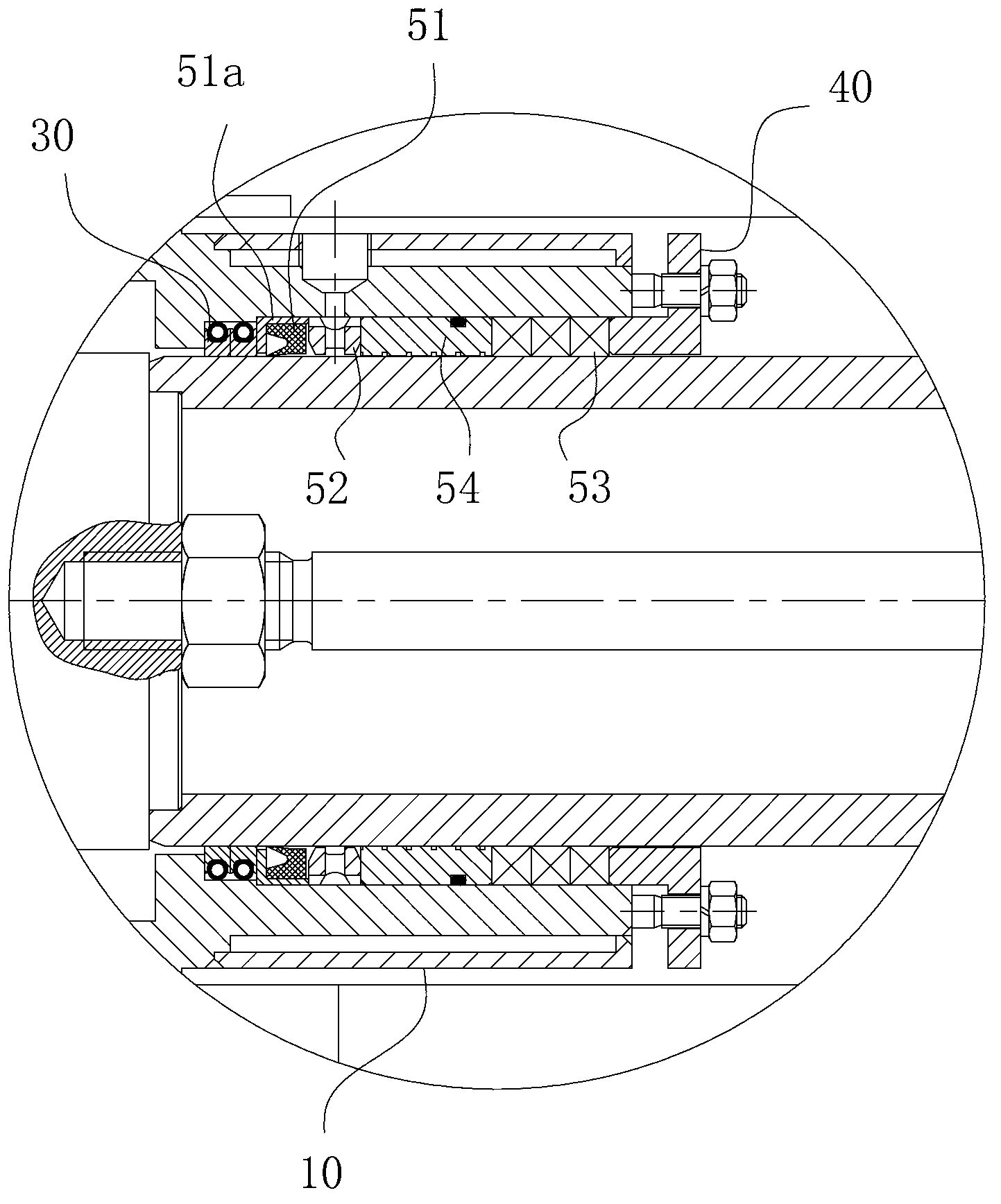

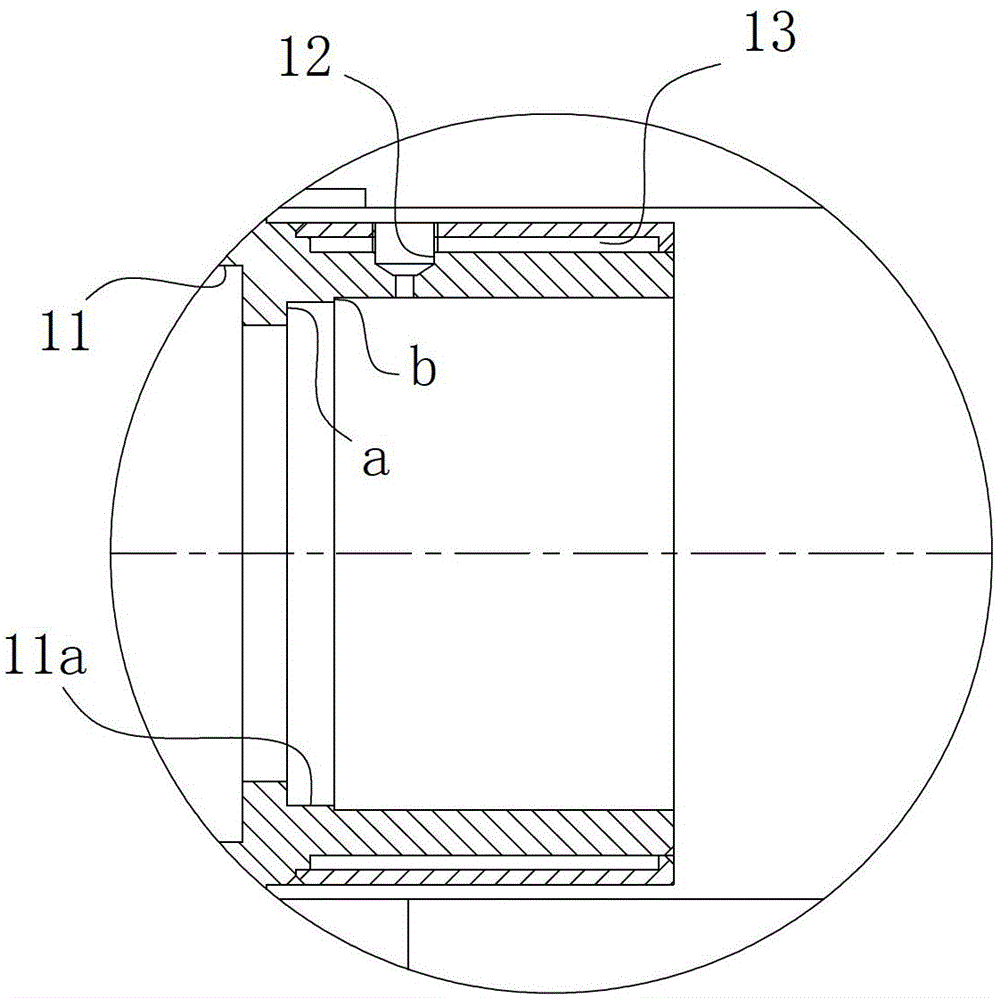

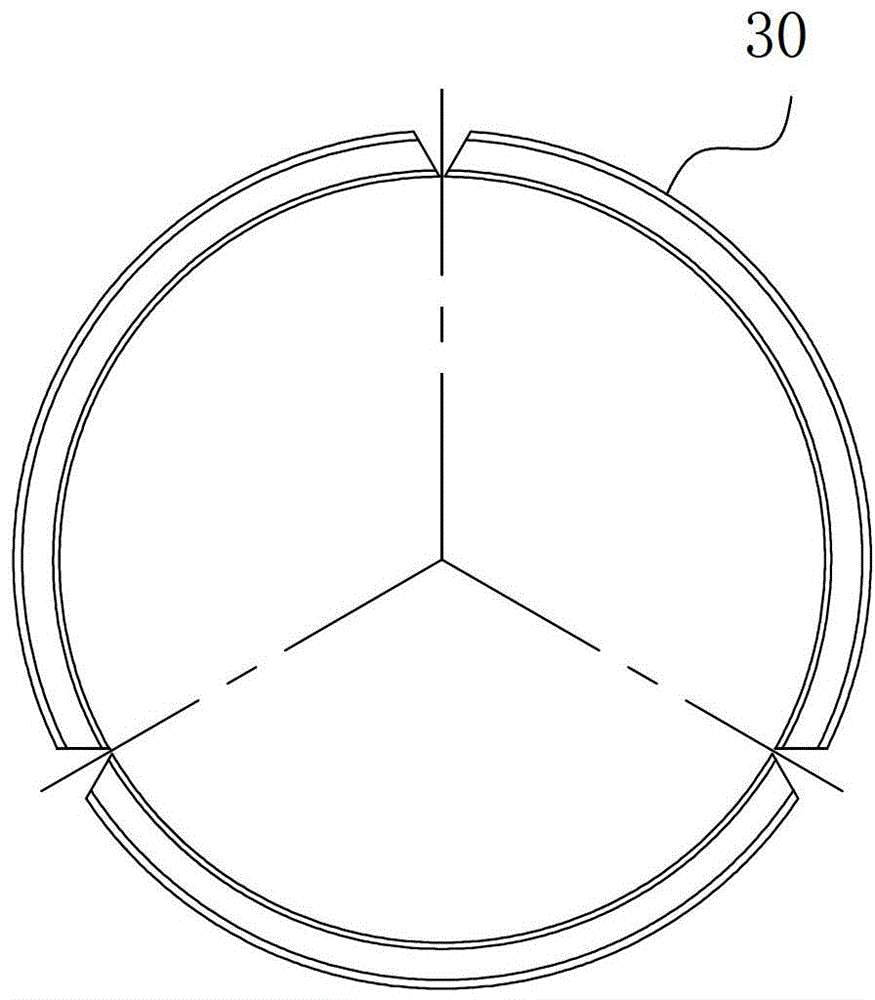

Combined sealing device for plunger pump

ActiveCN103306969ARealize the purpose of pre-protectionAvoid erosion and fragmentationPositive displacement pump componentsPumpsEngineeringCylinder block

The invention belongs to the field of solid pumps, and particularly relates to a combined sealing device for a plunger pump for pumping high-viscosity media such as tar residue. The combined sealing device at least comprises a pump cylinder block with a plunger hole, and a plunger part matched with the plunger hole in a splicing manner, wherein the plunger part can reciprocate linearly along the plunger hole; a cavity defined by the front end of the plunger part and a hole wall of the plunger hole forms a pumping cavity for accommodating and squeezing materials; a sealing unit for filling a fit clearance between the plunger part and the plunger hole is sandwiched between a peripheral wall of the plunger part and the hole wall of the plunger hole; the combined sealing device for the plunger pump further comprises a scrape ring for scraping off the viscous materials from the peripheral wall of the plunger part and / or the hole wall of the plunger hole; the scrape ring is embedded into the hole wall of the plunger hole and / or the peripheral wall of the plunger part is sleeved with the scrape ring in a surrounding manner; the scrape ring isolates the sealing unit from the pumping cavity; and the combined sealing device can realize an effect of high-seal conveying of the solid materials in the combined sealing device, and effectively ensure long service lives of sealing parts in the plunger pump simultaneously.

Owner:合肥华升泵阀股份有限公司

Tubular escaping chute structure

InactiveCN104548396AHeavy loadImprove fire resistanceBuilding rescuePhysical exhaustionFire detector

The invention discloses a tubular escaping chute structure, and belongs to the field of fire-fighting. The chute is arranged in a building, is of a spiral bend structure from top to bottom and is of a tubular cavity structure; the two ends of the chute are provided with an entrance and an exit; the chute comprises a multi-layer structure; the multi-layer structure comprises a refractory layer on the outer layer of the chute, a bearing layer on the middle layer and a water layer; the inner wall of the chute is provided with a fire detector; the periphery of the entrance is connected with a water supply device and an air supply device. By using the structure, the escaping speed can be quickened, the escaping time can be shortened, the physical exhaustion can be reduced and the death of people due to the smoke and the fire disaster can be reduced by using the chute under the conditions of fire disasters or other conditions, particularly under the condition that smoke enters the staircase.

Owner:ANYANG NORMAL UNIV

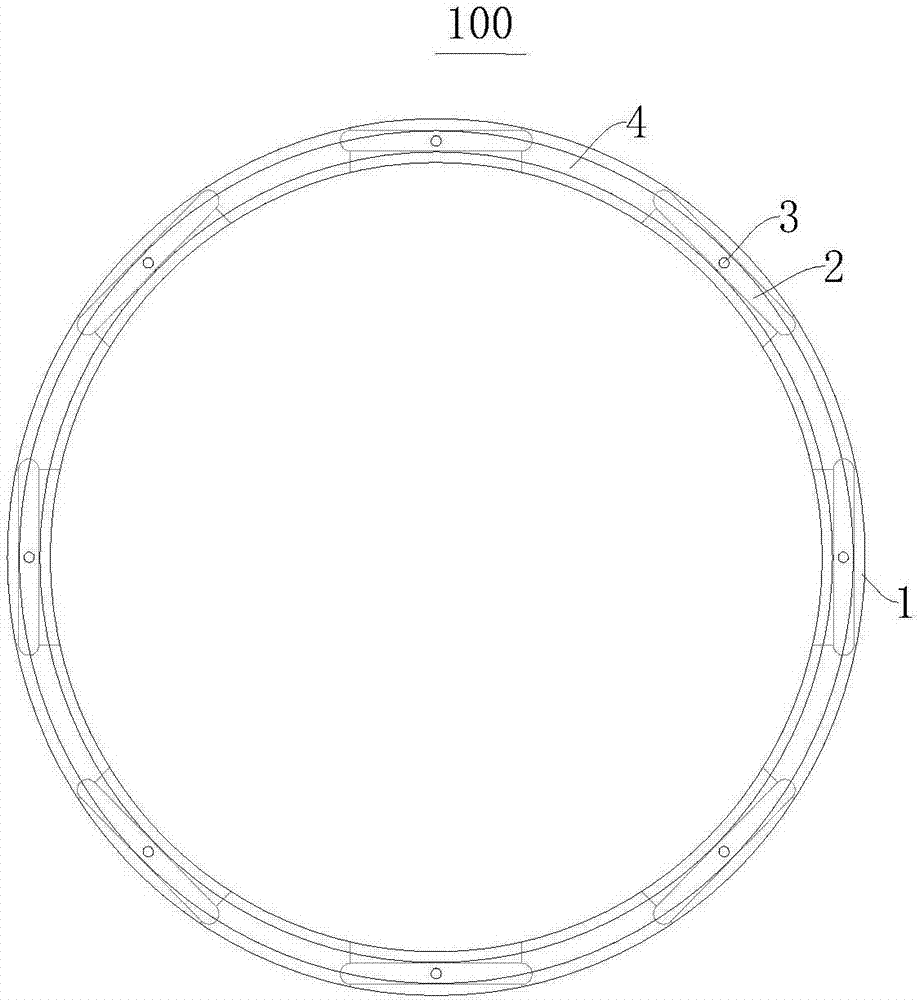

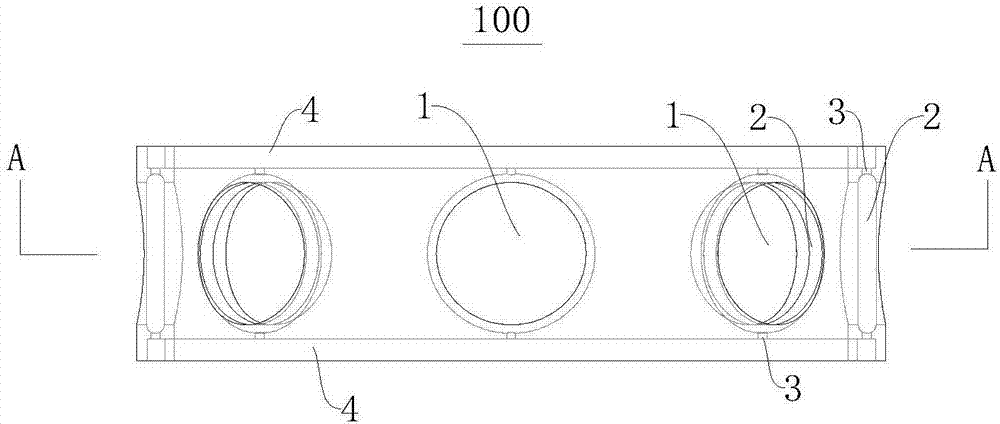

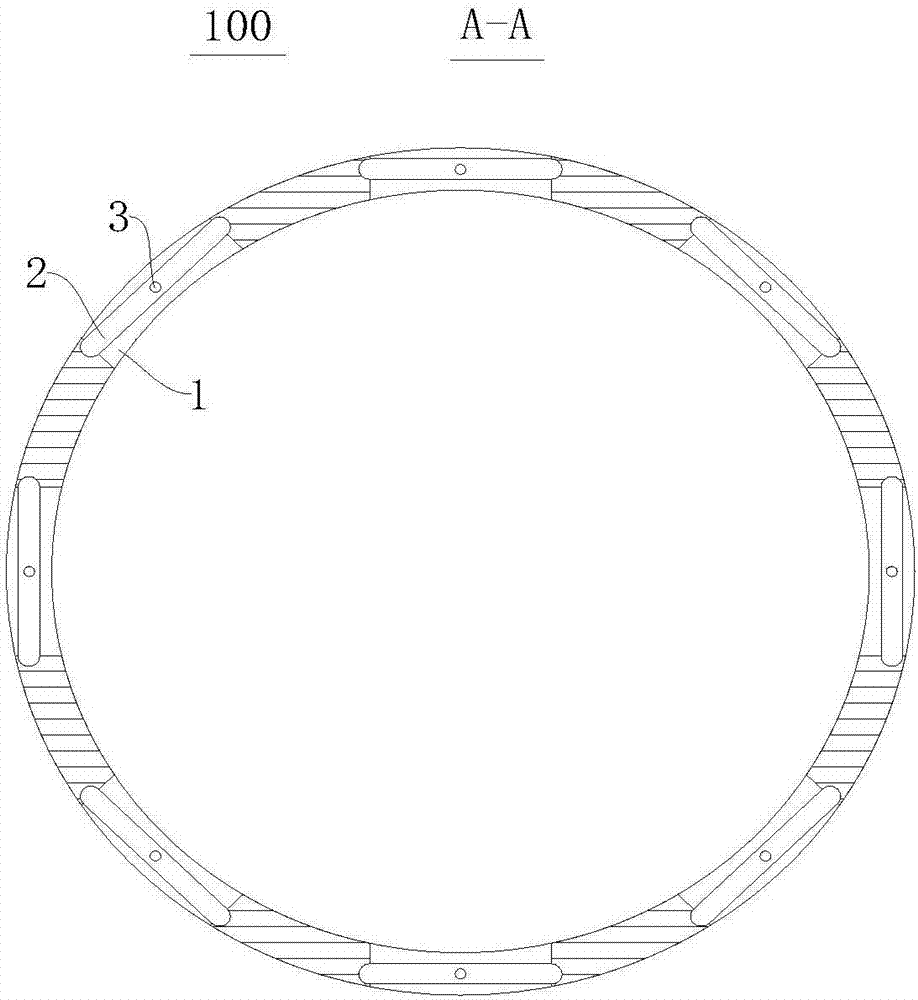

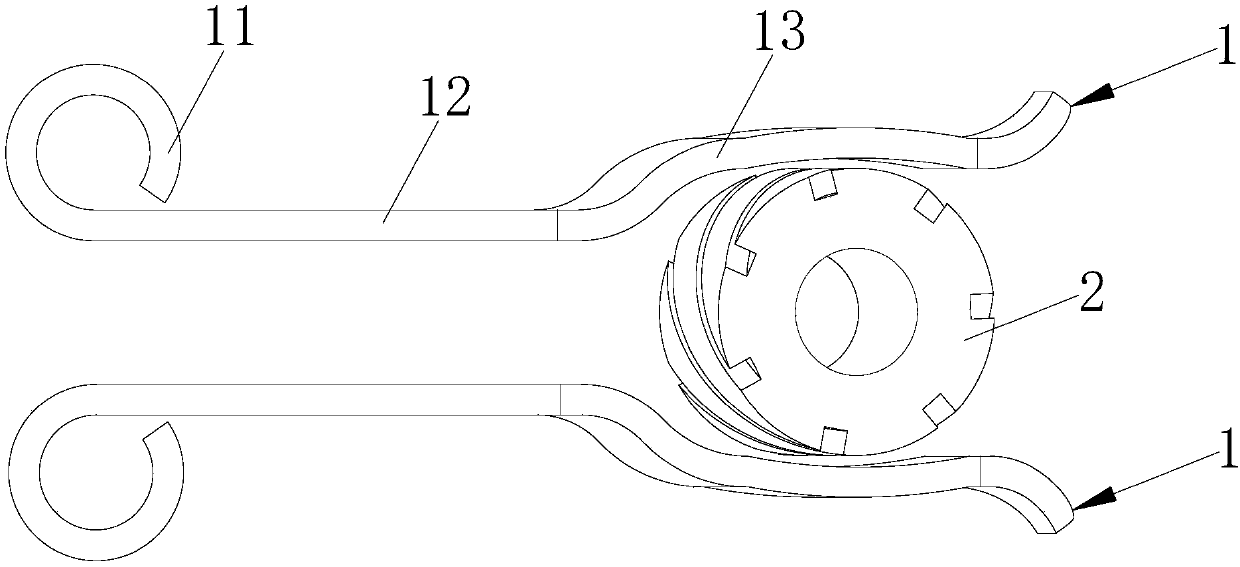

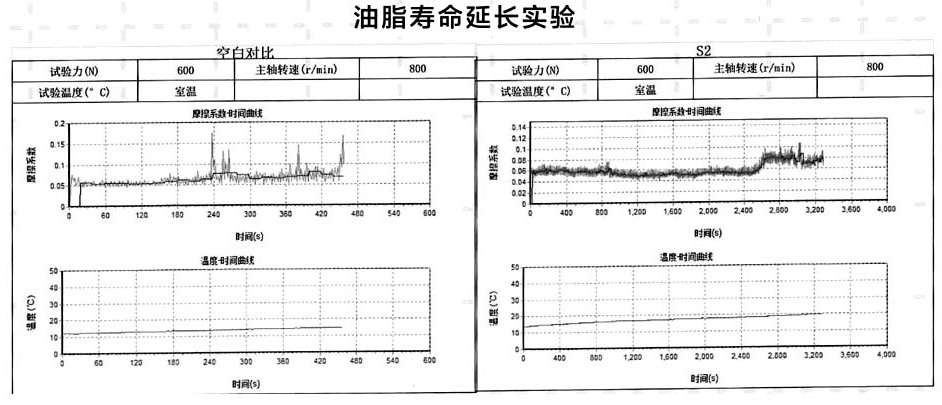

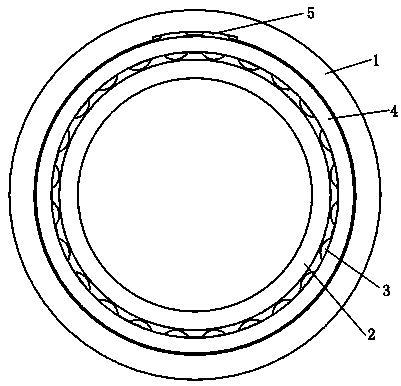

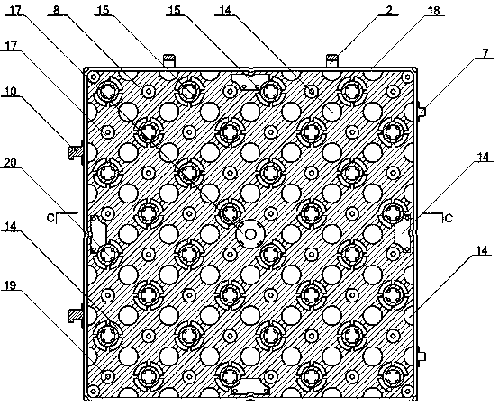

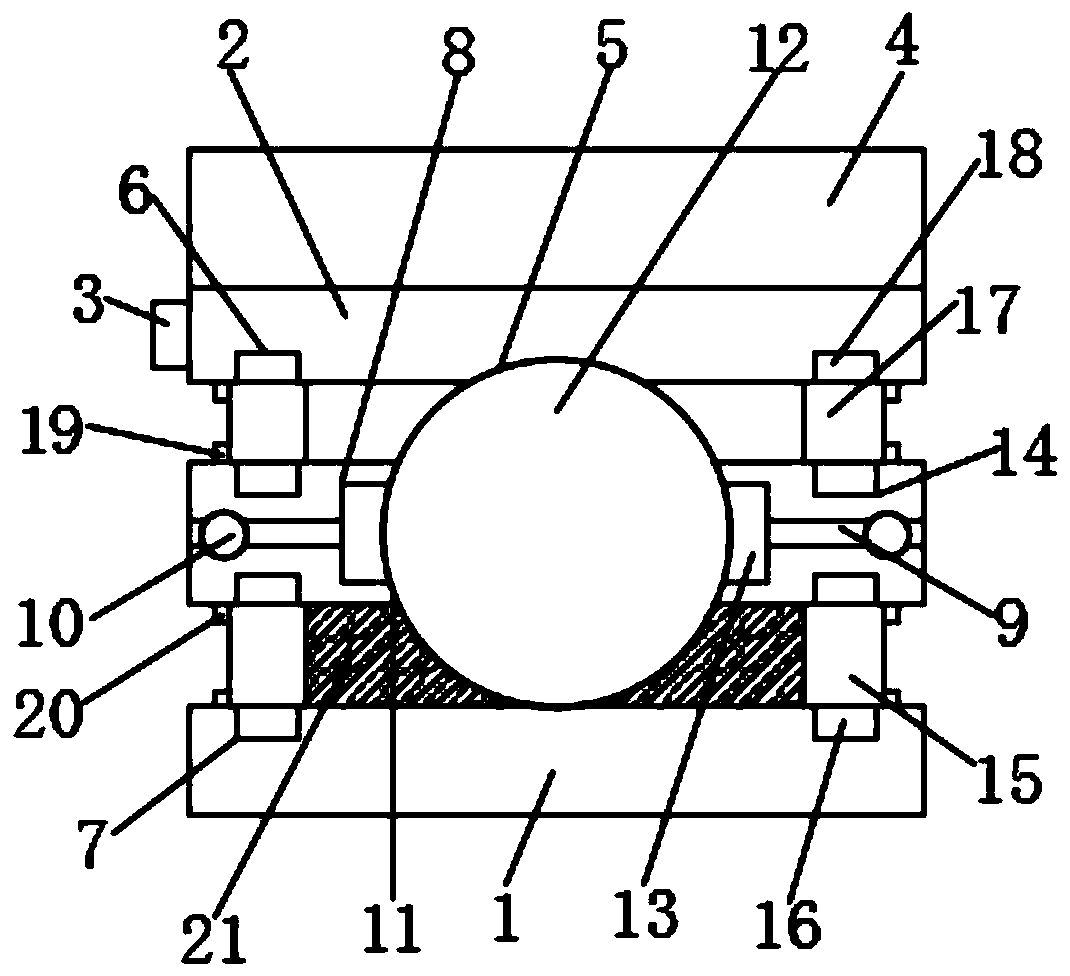

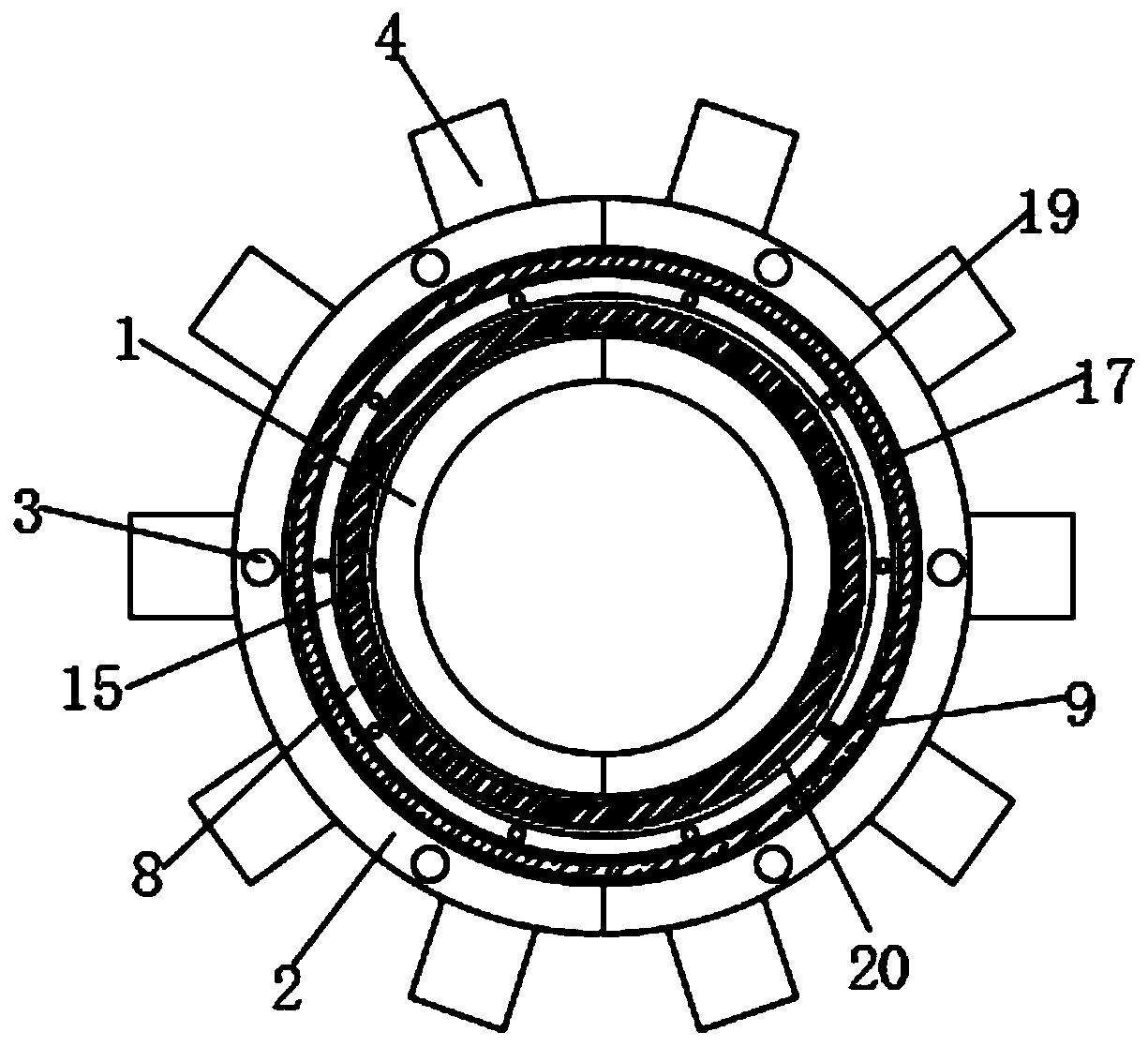

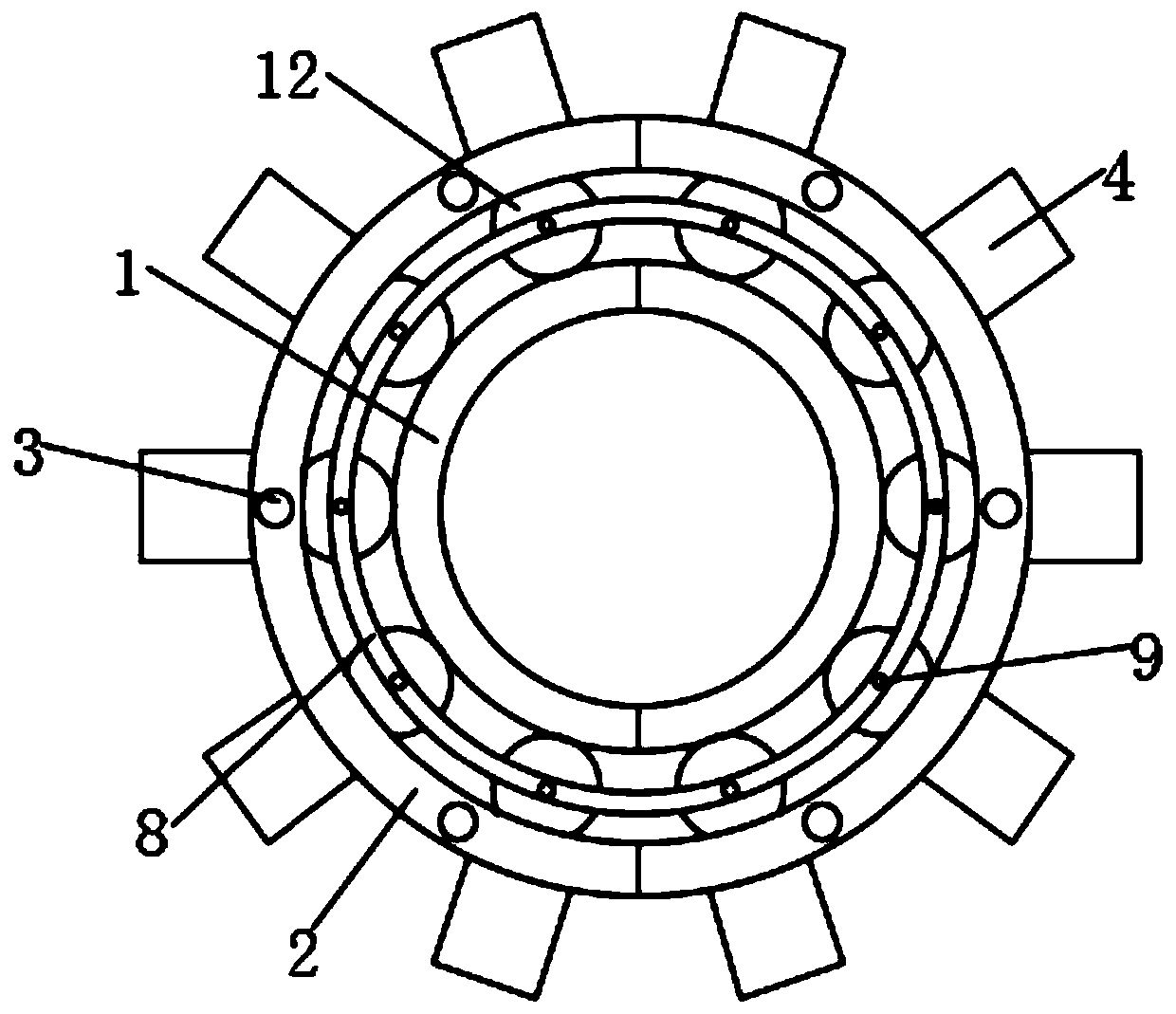

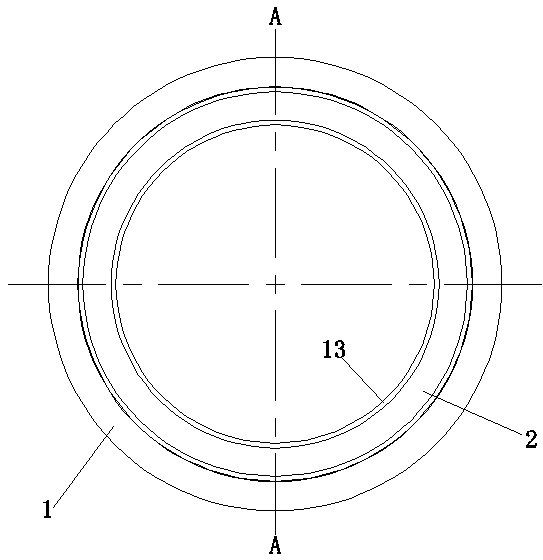

Deep groove ball bearing retainer and deep groove ball bearing

PendingCN107237824AExtended service lifeImprove wear resistanceShaftsBearing componentsBall bearingEngineering

The invention discloses a deep groove ball bearing retainer and a deep groove ball bearing. The deep groove ball bearing comprises a bearing inner ring, a bearing outer ring, rolling bodies and the retainer (100); the retainer (100) is located between the bearing inner ring and the bearing outer ring, and the rolling bodies are installed on the retainer (100); the retainer (100) comprises a retainer body, pockets (1) and ring slots (2); the pockets (1) are uniformly arranged on the retainer body, and rolling bodies are installed in the pockets (1); and the ring slots (2) are arranged in the pockets (1), and the ring slots are internally provided with lubricating oil. The retainer (100) is good in lubricating effect, the temperatures of the rolling bodies and wear to the retainer (100) can be lowered, the retainer is not liable to damage, and the service life of the retainer is prolonged.

Owner:徐州博丰轴承有限公司

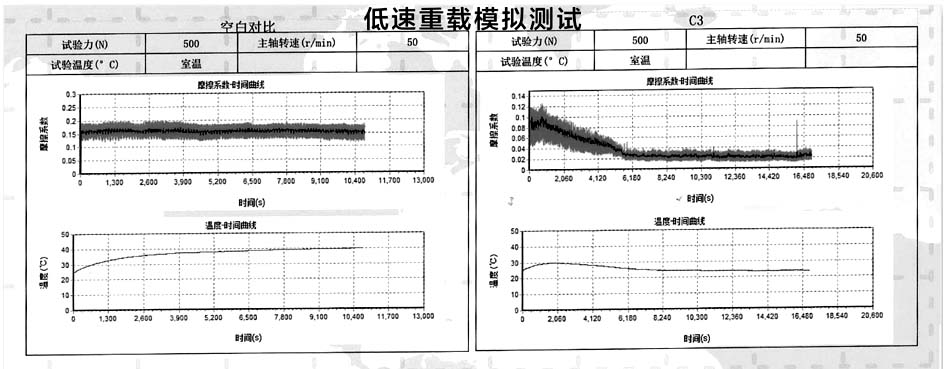

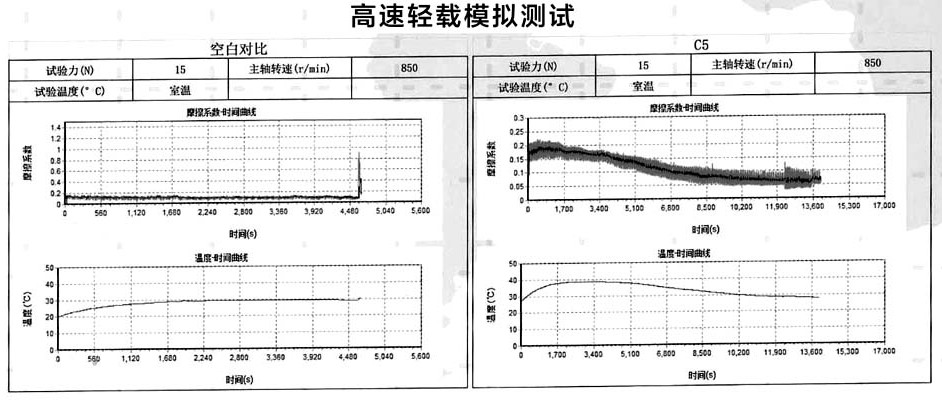

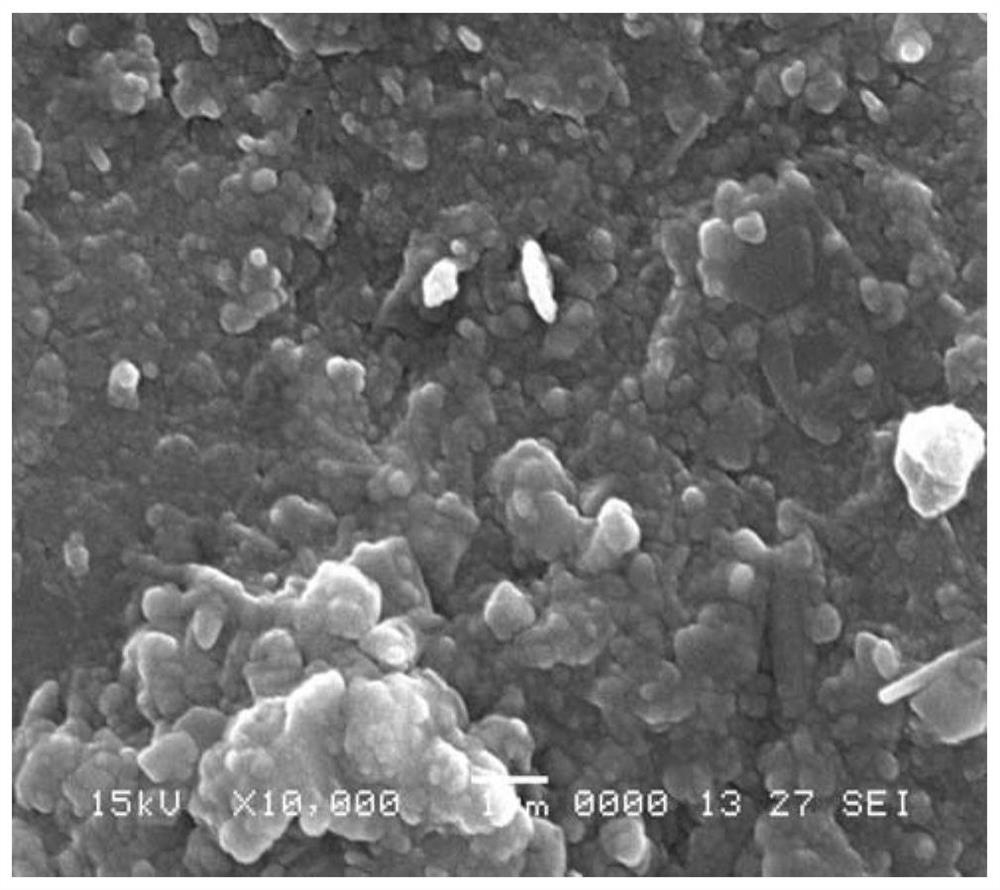

Composite lubricating grease for heavy load bearing and preparation method thereof

PendingCN107502405AUniform sizeImproves strength and hardnessCarbon preparation/purificationAdditivesLithiumEvaporation

The invention relates to the field of lubricating grease, in particular to composite lubricating grease for a heavy load bearing and a preparation method thereof. The composite lubricating grease is prepared from the following ingredients in percentage by weight: 99.2 to 99.8 percent of lithium-based lubricating grease and 0.2 to 0.8 percent of micro carbon spheres and nanometer particles. The micro carbon spheres and nanometer particles are uniformly distributed in the lithium-based lubricating grease by using ethanol as carriers. Compared with the existing ordinary lithium-based lubricating grease, the composite lubricating grease prepared after the ethanol evaporation has the advantage that the improvement is realized in aspects of friction heating, friction mark area and the like.

Owner:HENAN UNIV OF SCI & TECH

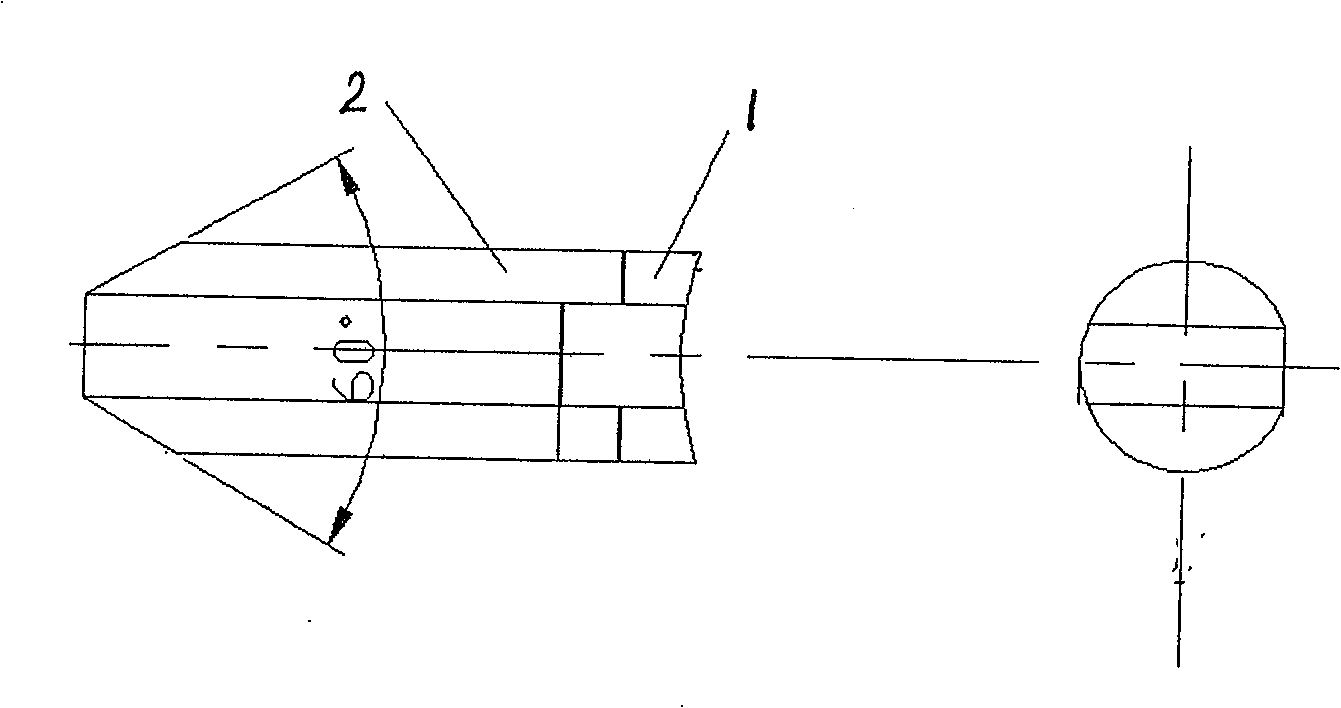

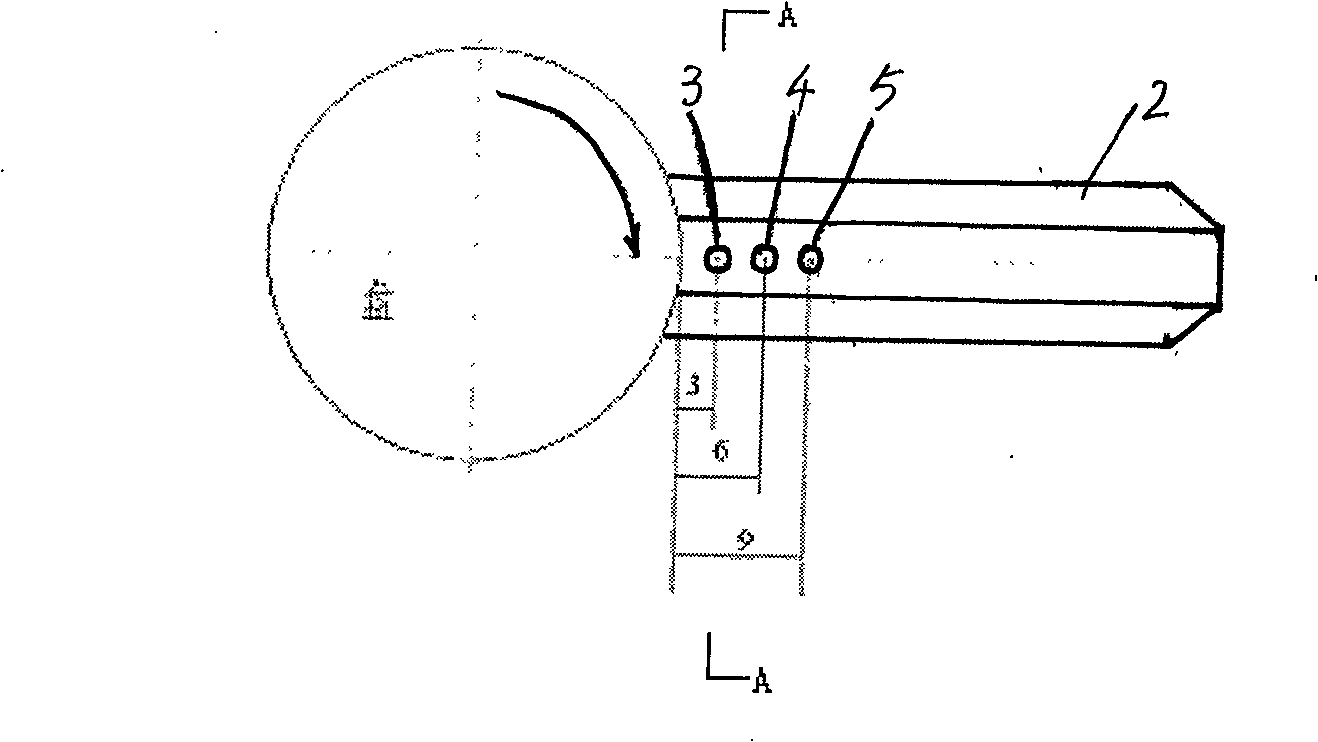

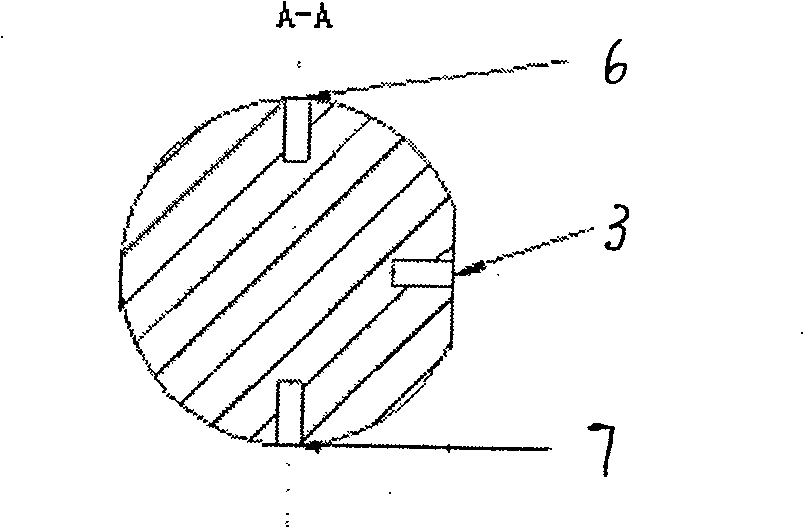

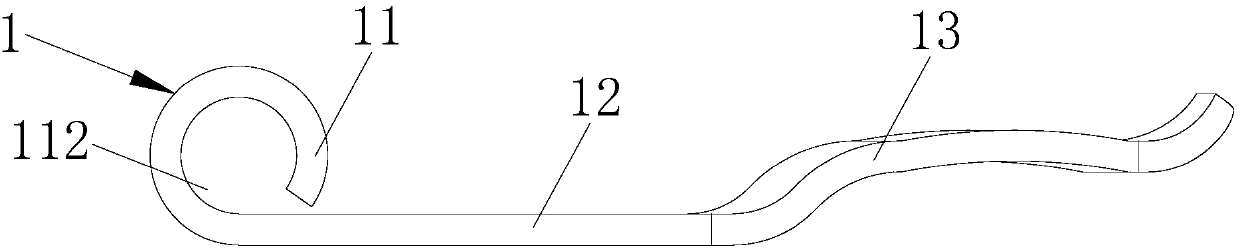

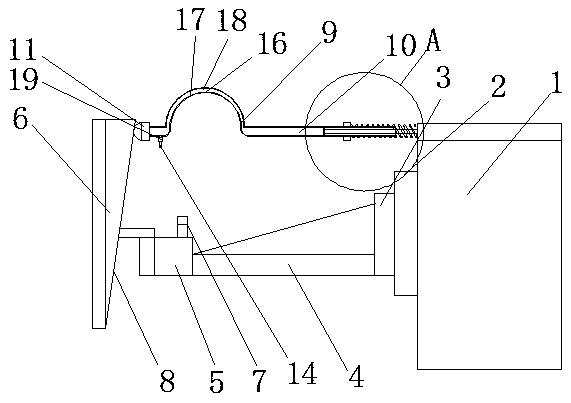

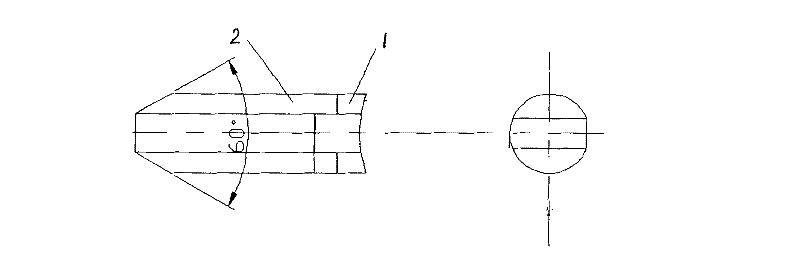

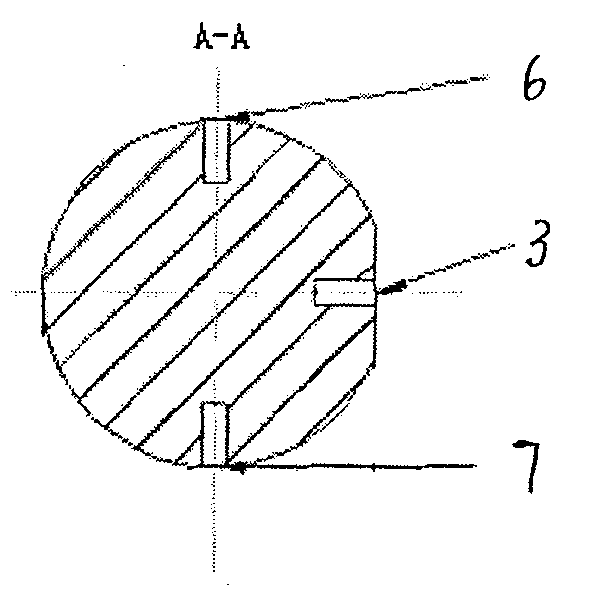

Regulation test method for friction temperature, and pin sample for the same

ActiveCN101319986AChange in heat transfer capacityImprove thermal conductivityTemperatue controlThermometers using electric/magnetic elementsMetallic materialsEngineering

The invention relates to the regulation test of friction temperature which belongs to a method and simultaneously relates to a regulation test and pin sample structure which belongs to the test technology field. The method of the invention comprises the following steps: (1) the pin sample structure is divided into a friction body and a pin body on the back section and the friction body and the pin body are fixed into one integrated structure; (2) the friction body and the pin body are respectively made of materials with different thermal conductivities; (3) temperature measuring holes for placing thermocouples are respectively arranged near to the friction surface of the pin sample in radial direction and axial direction. The combined pin with front and back metal mechanical embedded sections is adopted and the thermal conduction capacity of the front section metal is changed through changing the material of the back section metal to regulate the friction temperature. Temperature measuring points which are distributed in radial direction and axial direction are adopted for measuring temperature simultaneously to monitor the temperature measuring stability of the thermocouples. Realizing the stability for measuring temperature, the regulation test of the friction temperature can obtain reliable friction temperature data, satisfy the requirement for regulating the friction temperature, ensuring the reliability of the regulation test of the friction temperature and is provided with wide application prospect.

Owner:HENAN UNIV OF SCI & TECH

Novel arc surface contact left and right contact strips applicable to static contact group

InactiveCN107680837APromote sportsSolve the disadvantages of unsecured loopsContact electric connectionEngineeringWork status

The invention discloses novel arc surface contact left and right contact strips applicable to a static contact group. A movable contact current collecting ring is arranged on one side of a contact main body; the contact main body consists of a shaft end, a main board and a contact end; the shaft end, the main board and the contact end adopt an integrated structure; the main board is arranged between the shaft end and the contact end; a mounting groove is formed in the centre of the shaft end; a terminal mounting hole is formed in one end of the shaft end in a run-through manner; and contact convex points are arranged on the outer surface of the contact end at equal intervals. According to the novel arc surface contact left and right contact strips applicable to the static contact group, the contact end of the contact main body is in direct contact with the movable contact current collecting ring, so that the contact end can properly clamp the movable contact current collecting ring tightly to generate a high power-on effect; when the contact main body and the movable contact current collecting ring are in high-frequency contact, a high-abrasion-resistant and high-strength working state is achieved; and therefore, the service lives of the contact main body and the movable contact current collecting ring are prolonged jointly, and the safety performance is improved.

Owner:西安晶海中德铁路电气有限公司

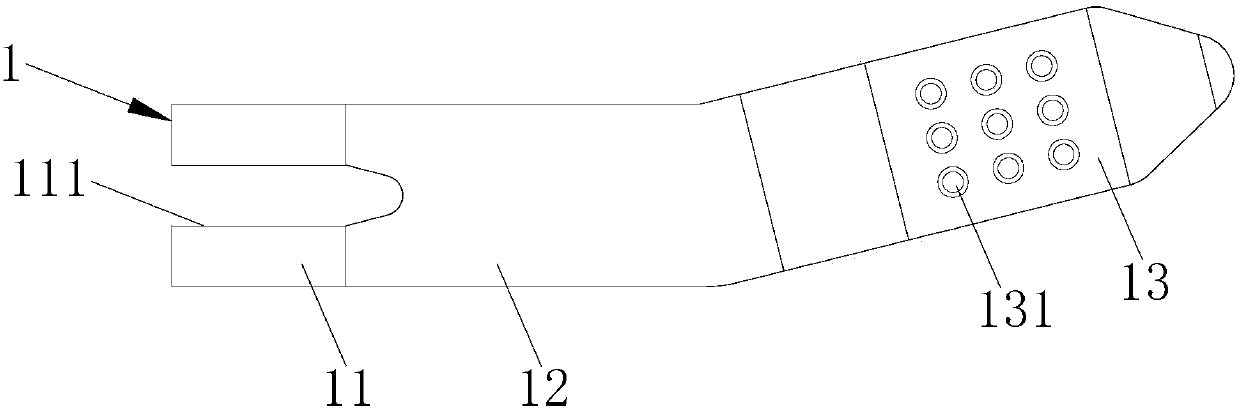

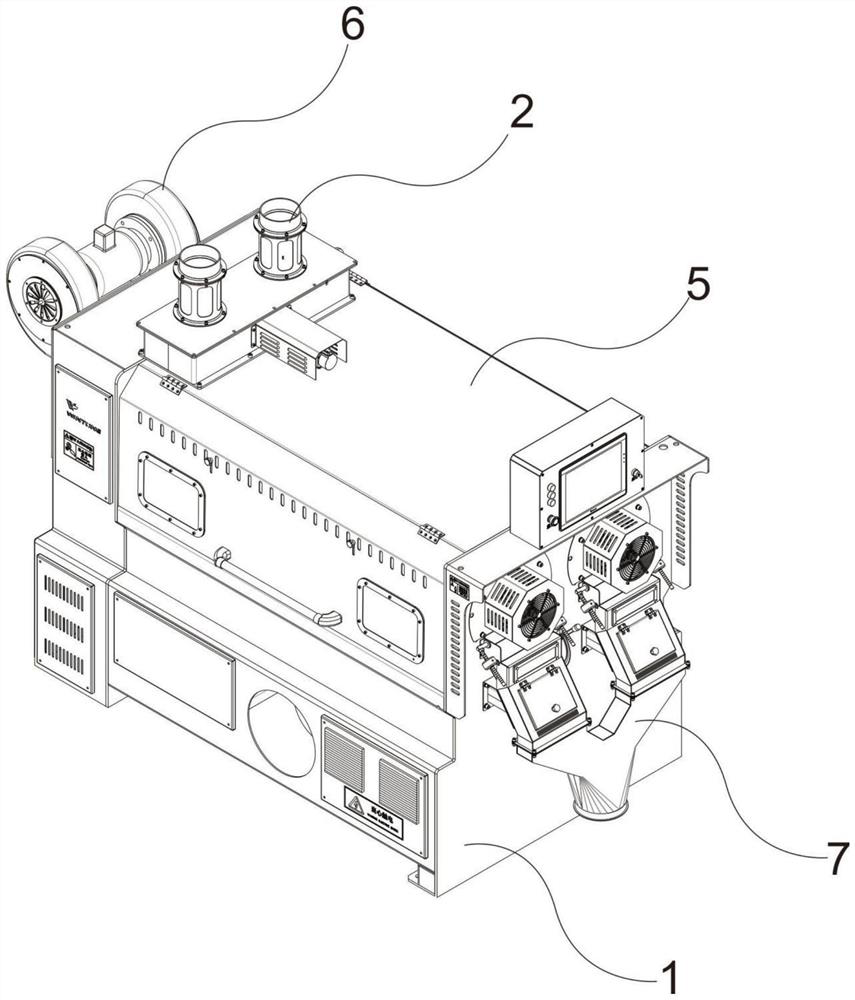

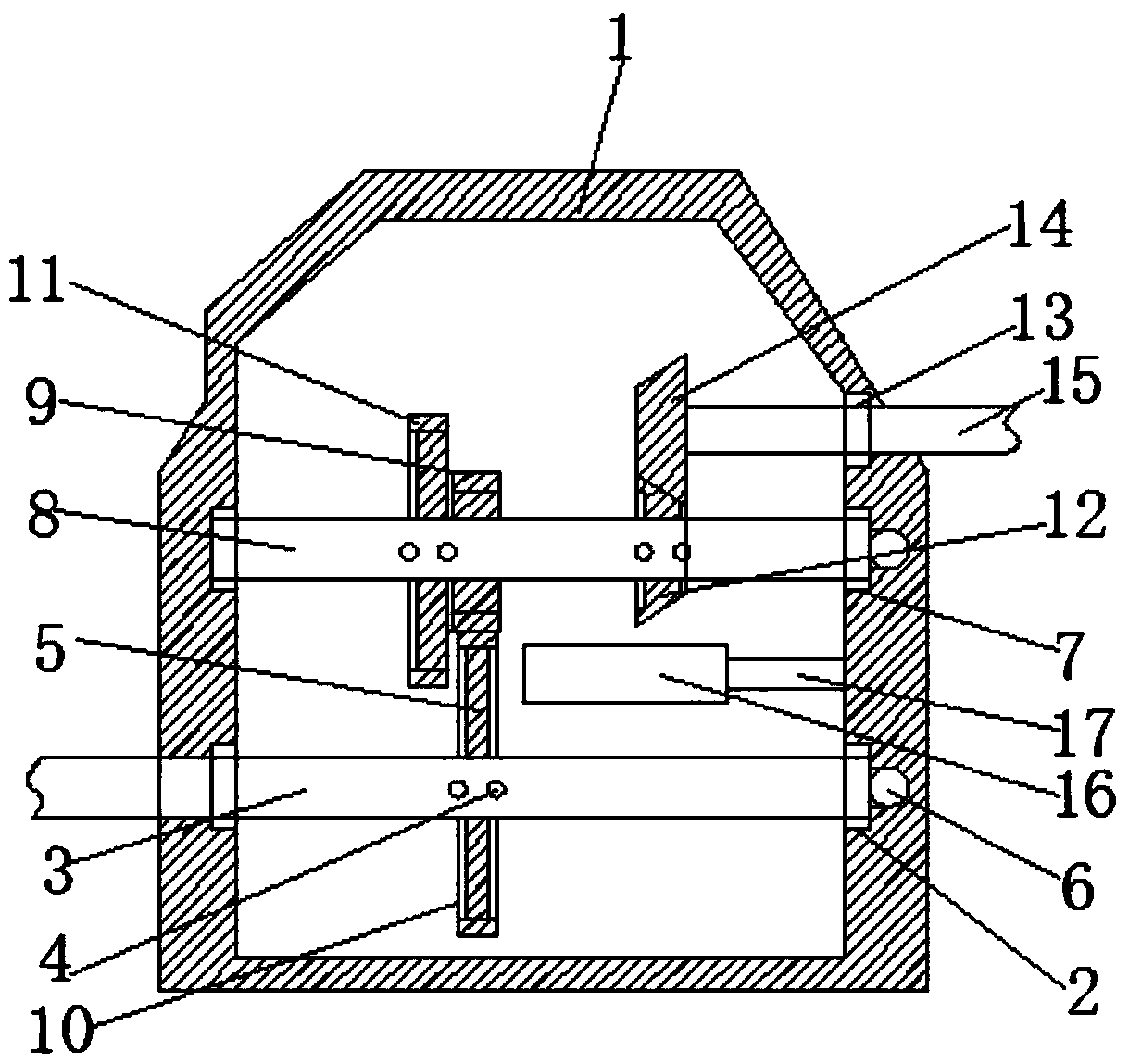

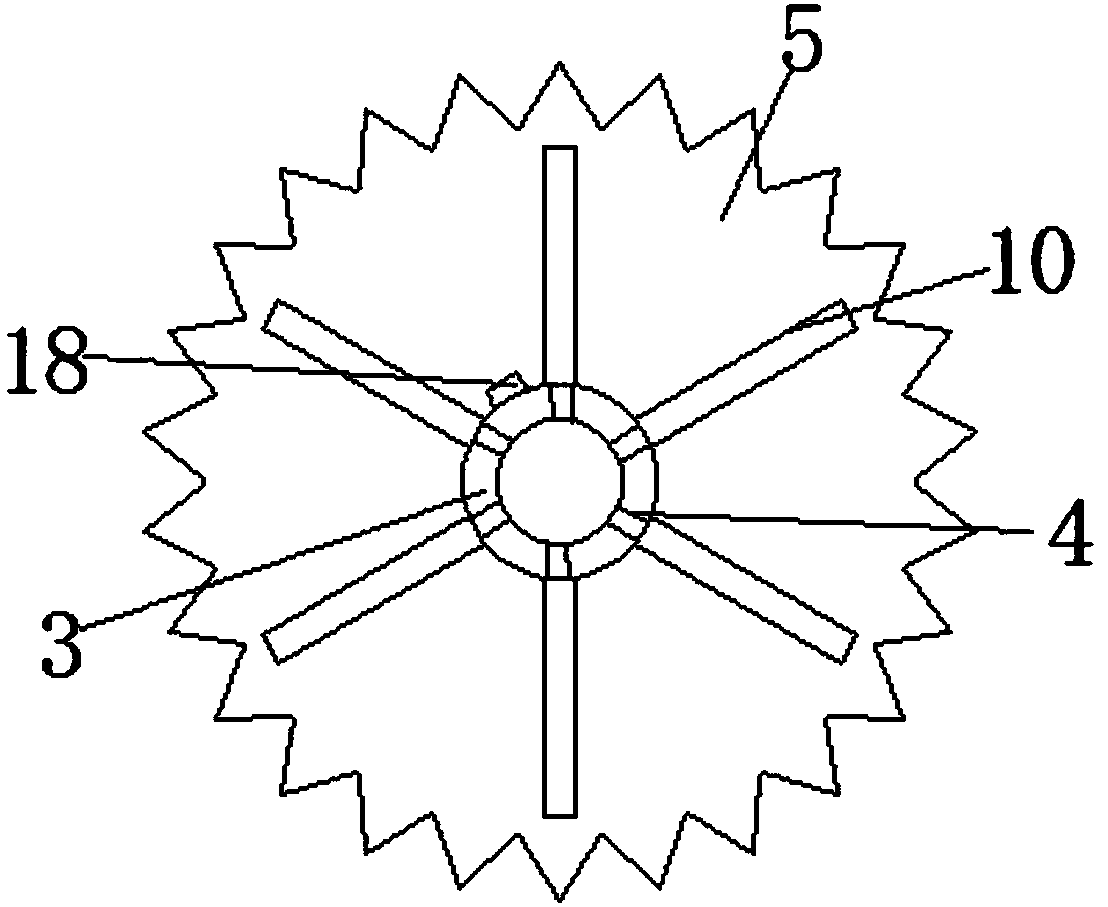

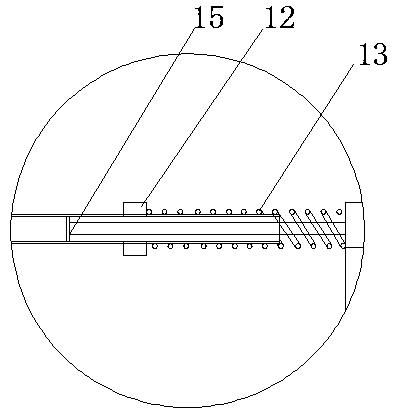

Intelligent flexible bran and fine broken rice separator

PendingCN113262837AEasy to separateMildew removalGrain huskingGrain polishingRotational axisElectric machine

The invention discloses an intelligent flexible bran and fine broken rice separator. The separator comprises a rack as well as a rubbing and polishing system, an air inlet system, a feed port, a discharge system, a motor, a bran discharge channel and a shell which are arranged on the rack, wherein the rubbing and polishing system comprises a rotor, a rotary sifting system and a driven belt pulley, the rotor is a rotating shaft, the driven belt pulley is fixedly mounted at the tail part of the rotating shaft, the driven belt pulley is connected with the motor through a belt, the motor drives the rotor to rotate, the rotary sifting system is of a cylindrical barrel-shaped structure, is arranged outside the rotor in a sleeving mode, is fixedly mounted on a rotary support of the rack and is driven by a special gear motor to be combined with a main shaft assembly to conduct same-direction differential rotation to perform circular motion, the feed port is formed in the upper portion of the rubbing and polishing system, a net is arranged outside the rotary sifting system, the size of net holes is set to enable rice bran to pass through and enable fine broken rice not to pass through, the bran discharge channel is mounted on the lower portion of the rotary sifting system, an external air net connector is arranged at a port of the bran discharge channel, the rotor and the rotary sifting system are provided with the rubbing and polishing rods, so that the rubbing and polishing efficiency is greatly improved during working, air is supplied to the space between the rotor and the rotary sifting system during rubbing and polishing, the friction temperature during separation of bran and fine broken rice is reduced, the quality of the separated fine broken rice is guaranteed, and rice bran can be discharged quickly.

Owner:鲁山县华豫万通工程技术有限公司

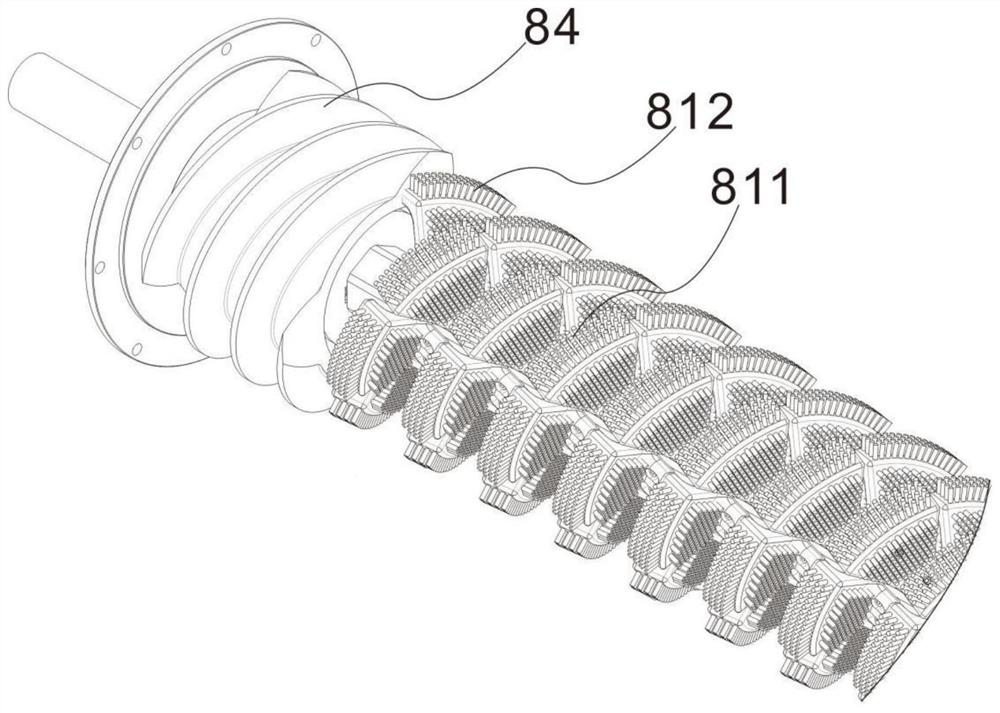

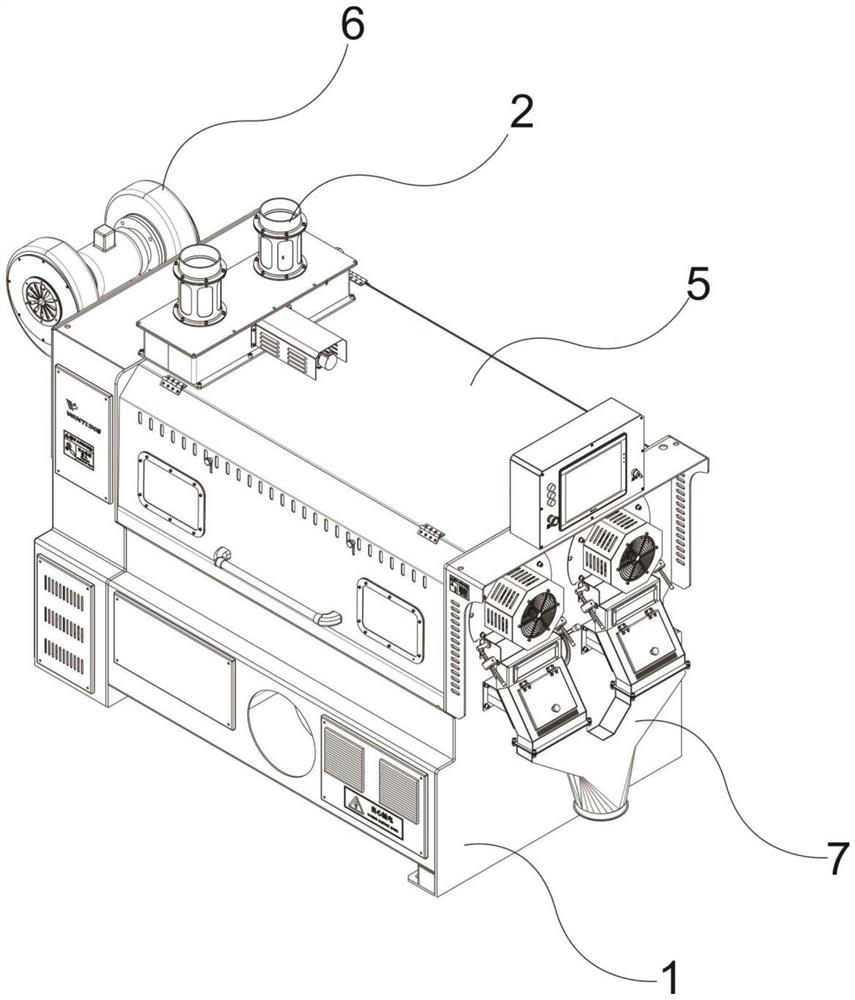

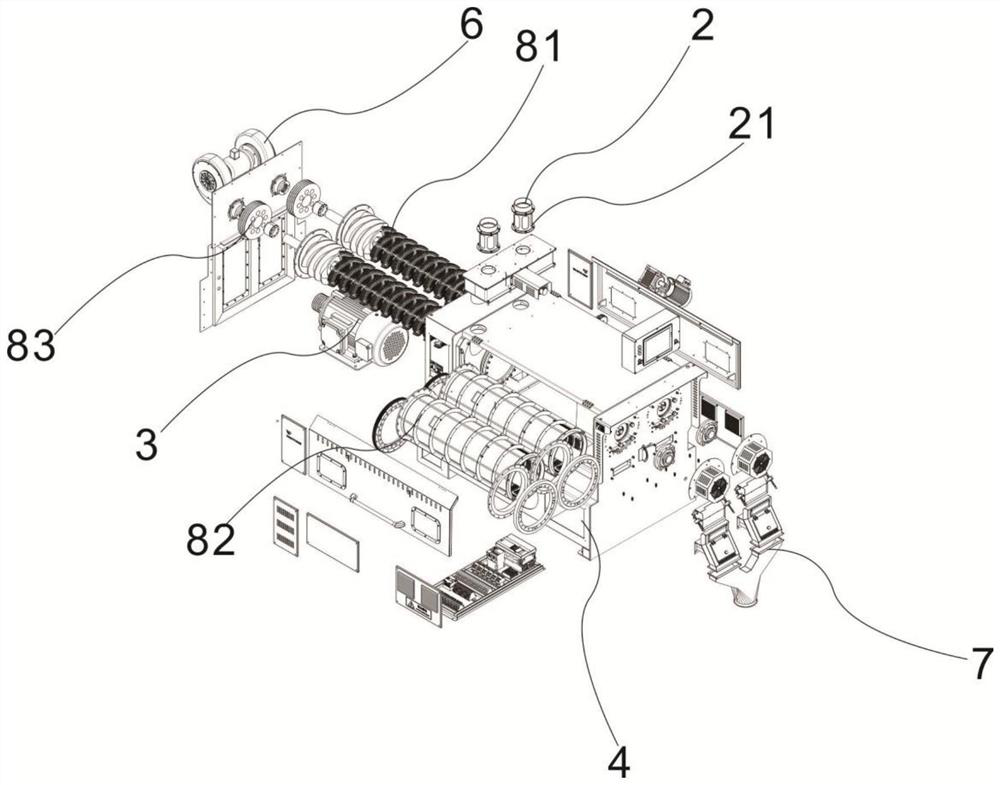

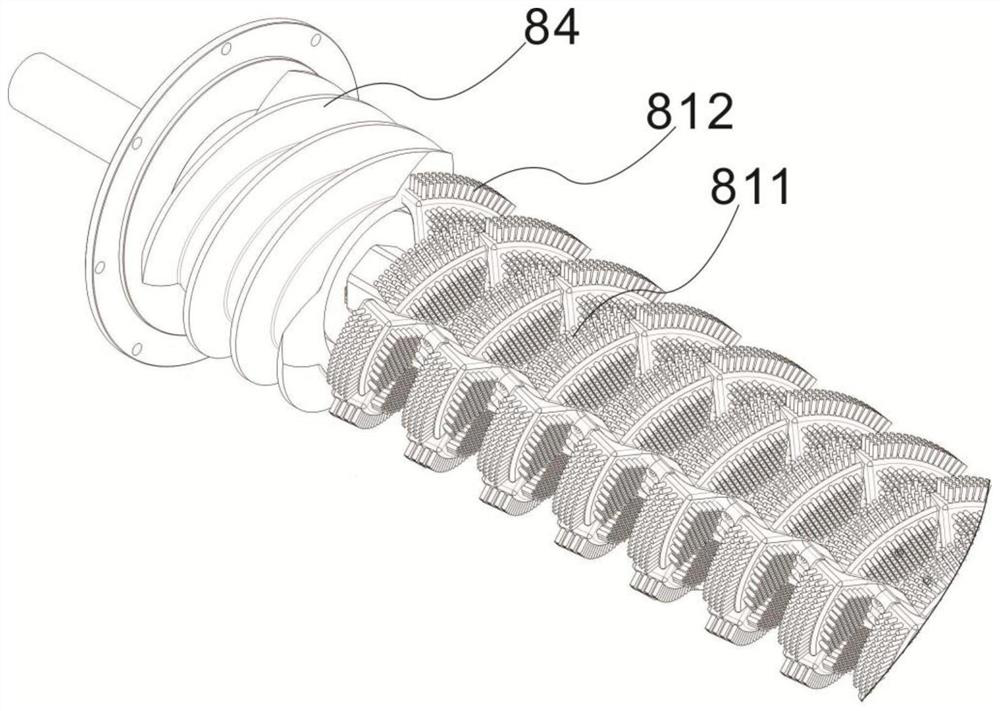

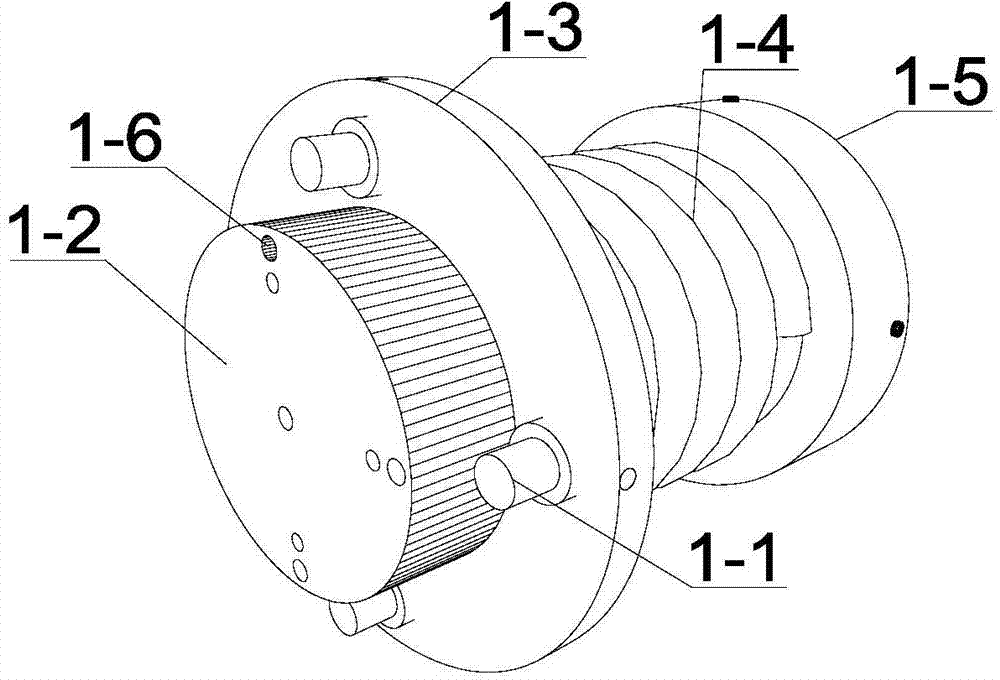

Intelligent flexible rice rubbing and polishing machine

PendingCN113368925AImprove the efficiency of rubbingLower friction temperatureGrain huskingGrain polishingRotational axisElectric machine

The invention discloses an intelligent flexible rice rubbing and polishing machine. The intelligent flexible rice rubbing and polishing machine comprises a rack, and a rubbing and polishing system, an air inlet system, a feed port, a discharge system, a motor, a bran outlet channel and a casing which are arranged on the rack, the rubbing and polishing system comprises a rotor, a rotary screening system and a driven belt pulley, the rotor is a rotating shaft, the driven belt pulley is fixedly mounted at the tail part of the rotating shaft, the driven belt pulley is connected with the motor through a belt, the rotor is driven by the motor to rotate, the rotary screening system is of a cylindrical barrel-shaped structure, is arranged outside the rotor in a sleeving mode and is fixedly installed on the rack, the feeding port is formed in the upper portion of the rubbing and polishing system, the discharge system comprises a discharging port and is installed at the tail of the rotor, a net is arranged outside the rotary screening system, the size of meshes is set to enable rice bran to pass through and enable rice not to pass through, the bran outlet channel is installed on the lower portion of the rotary screening system, an external air net connector is arranged at a port of the bran outlet channel, an air supply system is an air blower, and an air outlet of the air blower communicates with the rotor. Therefore, during working, the rubbing and polishing efficiency is greatly improved, air is supplied to the space between the rotor and the rotary screening system during rubbing and polishing, the friction temperature of rice during rubbing and polishing is reduced, and the quality of the rice is guaranteed.

Owner:鲁山县华豫万通工程技术有限公司

a metal repair agent

ActiveCN111363603BReduce manufacturing costExcellent self-healing performanceAdditivesFirming agentMechanical equipment

Owner:郑州泷劲耐磨材料有限公司

Novel high-speed and high-precision all-ceramic roller bearing

InactiveCN110145539ASimple structureOptimize the installation processRoller bearingsShaftsNon destructiveEngineering

The present invention provides a novel high-speed and high-precision all-ceramic roller bearing, comprising an outer ring, an inner ring, rollers and a cage; a retaining shoulder at one side of the outer ring is slotted to form a groove with the radian being 30 degrees, and the height of the groove is half of the retaining shoulder of the outer ring; the inner diameter of the inner ring is 70% ofthe outer diameter of the outer ring; channels of both the outer ring and the inner ring are coated with a layer of graphene. The novel high-speed and high-precision all-ceramic roller bearing has theadvantages and effects of optimized outer ring structure with the retaining shoulder of the roller bearing, improved installation process, reduced production costs and improved performance of the roller bearing, and the non-destructive installation of the silicon nitride all-ceramic roller bearing is achieved.

Owner:SHENYANG JIANZHU UNIVERSITY

Gear speed change mechanism with efficient lubricating effect

InactiveCN109931368AEfficient lubrication effectThe lubrication effect is achievedToothed gearingsGear lubrication/coolingMechanical engineering

The invention provides a gear speed change mechanism with the efficient lubricating effect, and relates to the field of cars. The gear speed change mechanism with the efficient lubricating effect comprises a gearbox body, two first bearings are fixedly connected to the inner wall of the gearbox body, the inner rings of the two first bearings are fixedly sleeved with input shafts, the input shaftsare hollow, the ends, away from the right side of the inner wall of the gearbox body, of the input shafts penetrate through the gearbox body and extend to the outer portion of the gearbox body, a driving gear is fixedly inserted to the position, located on the outer surfaces of the input shafts, in the gearbox body, and a first transmission gear is engaged to the tooth grain position of the driving gear. According to the gear speed change mechanism with the efficient lubricating effect, through a lubricating oil pump, lubricating oil in the gearbox body can be conveyed into the input shafts and a rotating shaft through lubricating oil pipes and branch pipes, through lubricating holes and lubricating grooves, lubricating oil flows to positions between gears, and the gears can be lubricated.

Owner:XIAN DONGJIA TRADE CO LTD

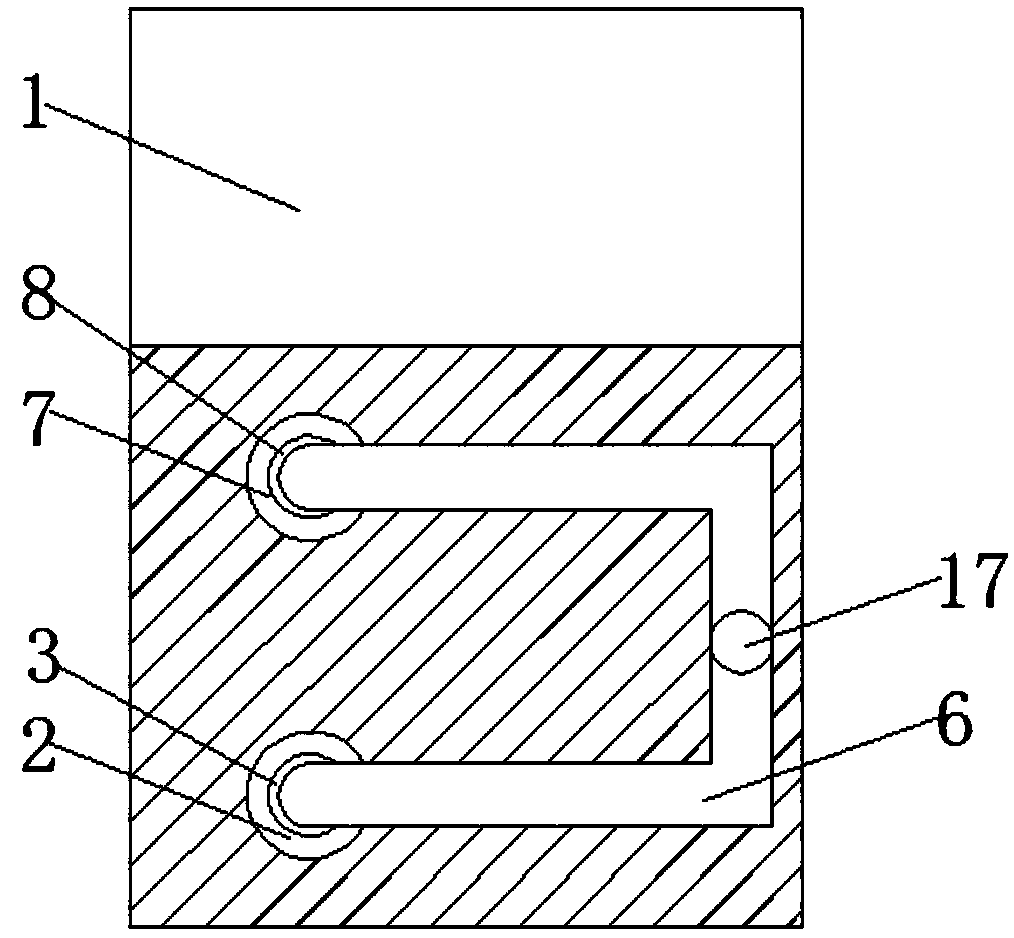

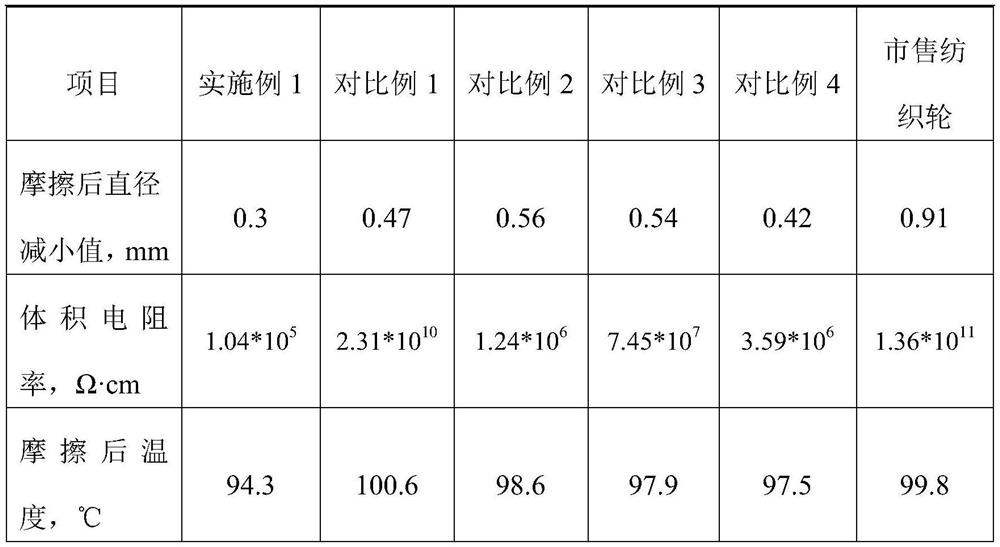

Rubber textile wheel sizing material as well as preparation method and application thereof

PendingCN113308030AImprove mechanical propertiesImprove electrical performanceCarbon nanotubePlasticizer

The invention discloses a rubber textile wheel sizing material as well as a preparation method and application thereof. The rubber textile wheel sizing material is prepared from the following raw materials in parts by weight: 50-100 parts of natural rubber; 0-50 parts of nitrile rubber; 1-20 parts of nano zinc oxide; 0.5 to 3 parts of stearic acid; 1 to 30 parts of graphene and carbon nanotubes; 20 to 120 parts of a filler; 1-8 parts of a coupling agent; 0-30 parts of a plasticizer; and 0.5 to 15 parts of a vulcanization accelerator. The textile wheel prepared from the rubber material has antistatic, low-heat-generation and wear-resistant properties, and overcomes the defects of relatively large wear, relatively large heat generation, no static electricity conduction and the like when the textile wheel is used. Compared with a rubber spinning wheel on the market, the abrasion loss is reduced by about 0.6 mm or above, the volume resistivity is reduced to be within the order of magnitude of 106 omega.cm, and the friction temperature is reduced by 5 DEG C or above.

Owner:CHEMCHINA ZHUZHOU RUBBER RES & DESIGN INST

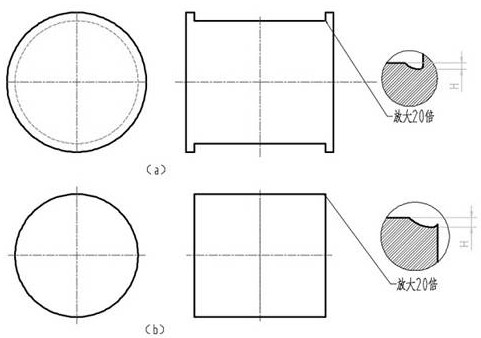

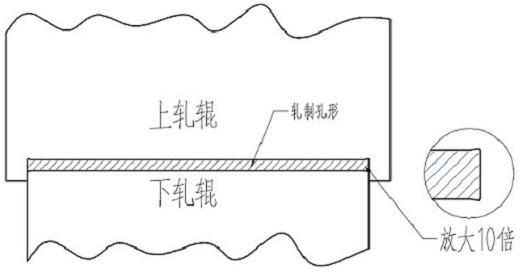

A Casting Roll Suitable for Reducing Edge Cracks of Magnesium Alloy Casting and Rolling Sheets

ActiveCN110340153BIncrease contact areaReduce wearRollsMetal rolling arrangementsEngineeringStructural engineering

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

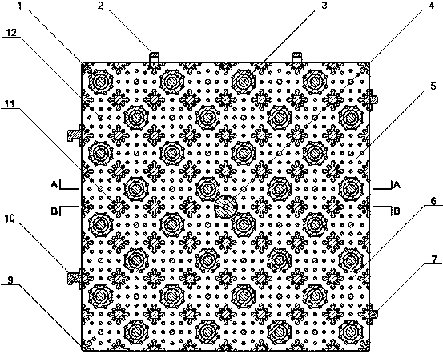

Four-season skiing pad with rolling balls

InactiveCN108499089AStable supportImprove wear resistanceSki bindingsWater-skiingEngineeringWear resistance

The invention discloses a four-season skiing pad with rolling balls. The skiing pad comprises a sliding pad module composed of the driven rolling balls, the driving rolling balls, an upper cover and asupporting base, and the driven rolling balls and the driving rolling balls are assembled in a rolling ball storage chamber in vertical columns of a base; the driving rolling balls in the base drivethe driven rolling balls to achieve mutual assistance, the friction force between the sliding pad and a sliding apparatus is small, and the skiing pad is not limited by the gradient, so that the skiing pad is high in sliding speed, high in wear resistance, stable, large in bending degree and low in noise, can continuously slide without spraying water, and is low in friction temperature, long in service life and convenient to pave and clean.

Owner:王运韬

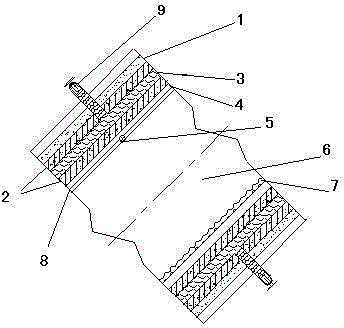

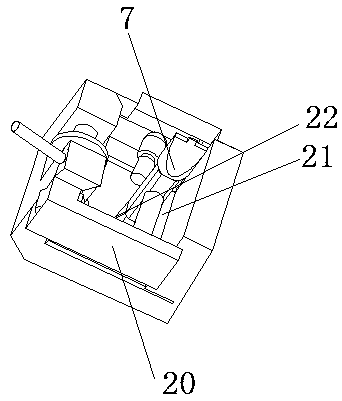

Swing Diamond Pen Dressing Grinding Wheel Device

ActiveCN109926922BLower friction temperatureReduce deformationAbrasive surface conditioning devicesGrinding/polishing safety devicesElectric machineryDrive motor

The invention provides an oscillating diamond pen dressing grinding wheel device which comprises a driving motor, a transition disc, a support, a diamond pen and a cooling liquid device. The driving motor is provided with a rotary table, the transition disc is installed on the rotary table, the support is installed at the front end of the transition disc, the tail end of the support is also provided with a fixing mechanism, the fixing mechanism is provided with a convex bedplate, the diamond pen is installed on the fixing mechanism, the convex platen is provided with an inclined plane inclinedfrom one end to the other end, the high point of the inclined plane is opposite to the diamond pen, the cooling liquid device comprises a telescopic liquid spraying device, one end of the telescopicliquid spraying device is fixed to the driving motor, the other end of the telescopic liquid spraying device abuts against the inclined plane, and the telescopic liquid spraying device is used for stretching and retracting along with the rotation of the inclined plane so as to spray cooling liquid. The support rotated along with the rotary table and the convex bedplate arranged on the support arerotated to enable the telescopic liquid spraying device to periodically spray cooling liquid, so that the friction temperature between the diamond pen and a grinding wheel in the machining process isreduced, and the deformation degree of the diamond pen is reduced.

Owner:浙江杭机股份有限公司

A 160km/h express truck brake pad for preventing thermal cracking of brake disc and manufacturing method thereof

ActiveCN109667865BImprove defects such as thermal crackingReduce wearOther chemical processesFriction liningButyl rubberTruck

The invention relates to a 160km / h express freight car brake pad for preventing thermal cracking of the brake disc and a manufacturing method thereof. The 160km / h express truck brake pads for preventing heat cracking of the brake discs include the following components and weight percentages: boron modified phenolic resin 20%-40%, butyl rubber 10%-18%, reinforcing fiber 6% ‑10%, carbon fiber 10%‑18%, sepiolite fiber 1%‑5%, vermiculite 1%‑8%, fluorite 2%‑8%, magnesium oxide 2%‑9%, clay 2%‑8 %, dispersant 0.2%‑3%. Compared with the prior art, the brake disc of the invention has a lower density, is more convenient to use, and can reduce vehicle quality. The brake pad of the present invention has a microporous structure, and the micropores play the role of heat dissipation, which can effectively reduce the friction temperature, the friction coefficient does not decline at a high temperature of 600°C, and the brake disc has no hot spots and cracks, effectively protecting the couple. The wear of the brake pads is low and the service life is longer than that of similar products.

Owner:SHANGHAI REINPHEN NEW MATERIAL TECH CO LTD

Combined sealing device for plunger pump

ActiveCN103306969BRealize the purpose of pre-protectionAvoid erosion and fragmentationPositive displacement pump componentsPumpsCylinder blockViscosity

Owner:合肥华升泵阀股份有限公司

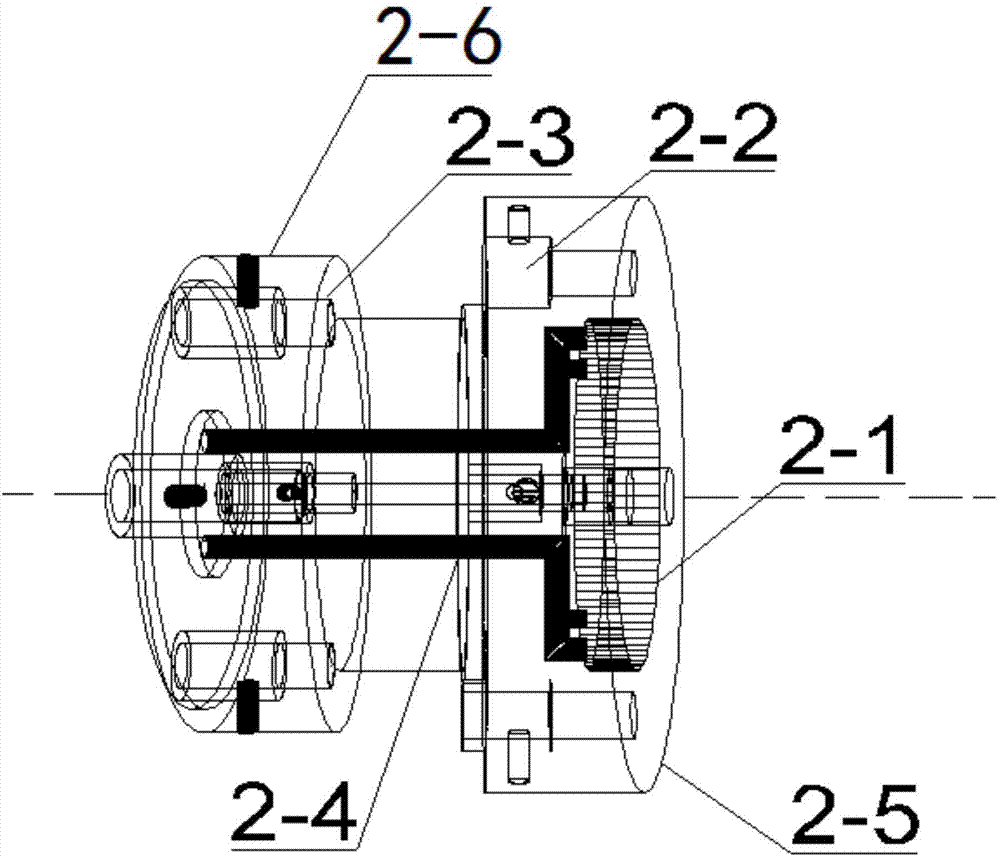

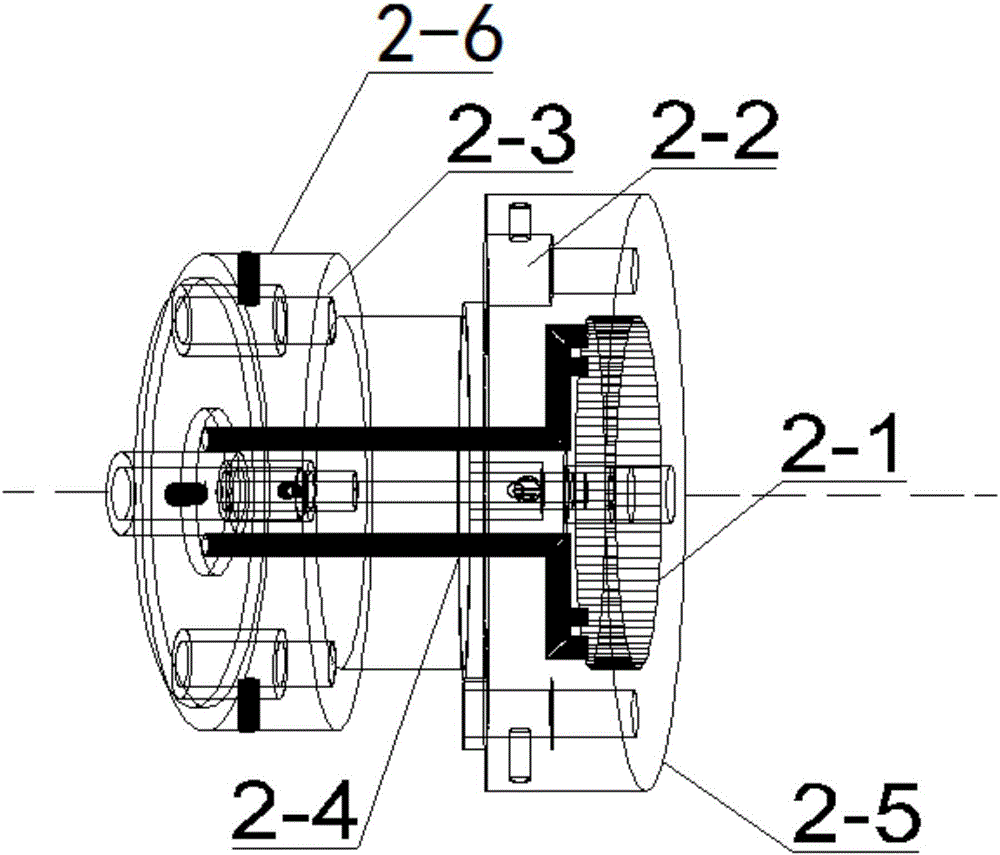

Bearing bush type conductive clutch

InactiveCN104767086ALower working temperatureImprove conductivityCoupling contact membersTwo-part coupling devicesAgricultural engineeringElectric wire

The invention discloses a bearing bush type conductive clutch. The bearing bush type conductive clutch is composed of a sub conductive clutch body and a main conductive clutch body, wherein the sub conductive clutch body comprises fixing bolts, a push-type conductive clutch disc convex column, a sub conductive clutch body flange plate, a reset spring, a spring base and cables; the main conductive clutch body comprises a sucked type conductive contact surface groove, fixing bolt grooves, a base push-type conductive clutch disc convex column mounting hole, electrical wires, a main conductive clutch body flange plate and a base. By means of the effective connection arrangement of all the parts of the sub conductive clutch body and the main conductive clutch body, the problems that the manufacturing cost of the conductive clutch is high, a conductive clutch disc is very hot and is severely burnt in the production process, the service life is short, the later period conductivity declines rapidly, and the smooth running of equipment is affected are solved, the usage range is further widened, and the service life is prolonged.

Owner:XUZHOU UNIV OF TECH +1

Regulation test method for friction temperature, and pin sample for the same

ActiveCN101319986BChange in heat transfer capacityImprove thermal conductivityTemperatue controlThermometers using electric/magnetic elementsMetallic materialsEngineering

Owner:HENAN UNIV OF SCI & TECH

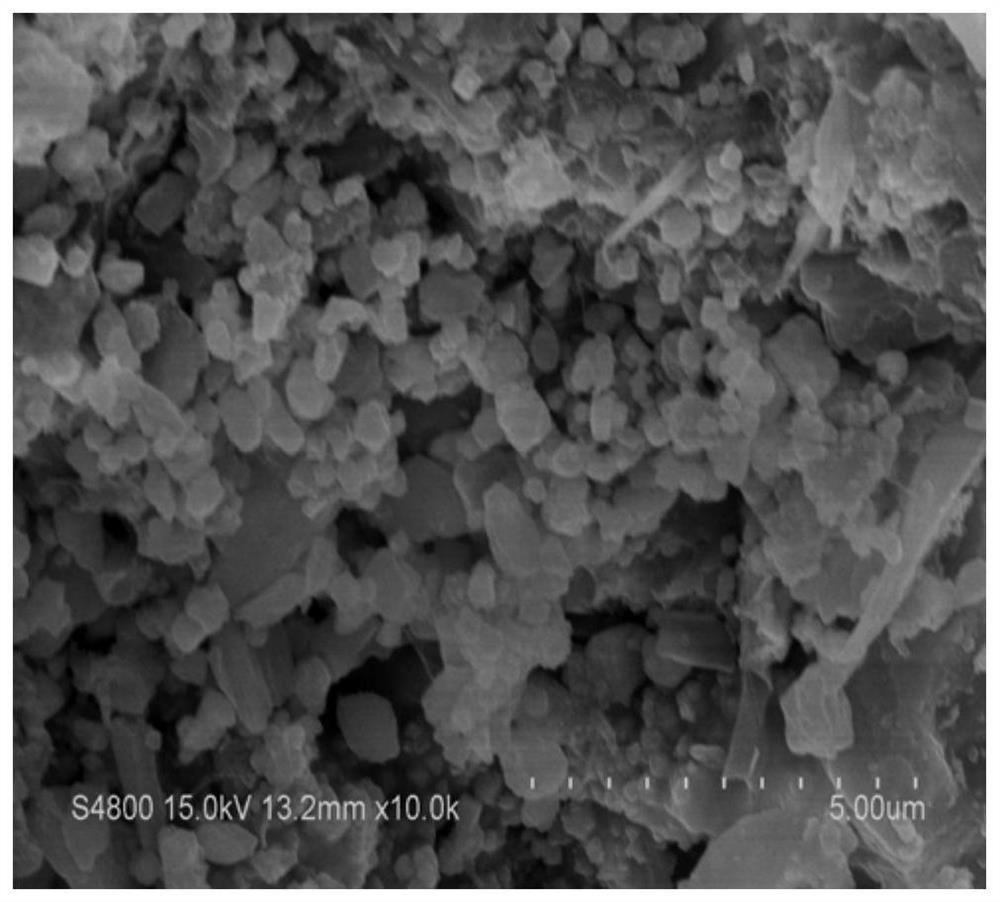

A kind of aluminum-tin-copper alloy-based bearing material and its preparation method

InactiveCN105734354BEasy to useImprove mechanical propertiesShaftsBearing componentsEnvironmental resistanceManganese

The invention belongs to the technical field of bearing pad materials, and discloses a preparation method of an aluminum-tin-copper alloy-based bearing pad material. The material uses endogenous TiB2 particles as a reinforcement, and an aluminum-tin-copper alloy as a matrix alloy; the main element of the matrix alloy is aluminum, and contains tin, copper, zinc, and manganese; the preparation method includes the following steps: (1) melting aluminum ingots, Get aluminum melt, add reactant K TiF6-KBF4 mixed salt, reaction aid Na3AlF6-MgCl Mixed salt, obtain the aluminum melt that contains endogenous TiB2 particle; (2) add aluminum in the aluminum melt that contains endogenous TiB2 particle Copper-zinc-manganese master alloy and tin block to obtain an alloy melt; (3) using NaCl-KCl-CaF2 mixed salt as a refining agent, refining the alloy melt, and pouring it into a mold to obtain the product. The aluminum-tin-copper alloy-based bearing material of the invention has excellent comprehensive performance, low production cost, and is environmentally friendly and pollution-free.

Owner:HENAN MECHANICAL & ELECTRICAL ENG COLLEGE

A bearing pad type conductive clutch

InactiveCN104767086BLower friction temperatureImprove conductivityCoupling contact membersTwo-part coupling devicesAgricultural engineeringElectric wire

The invention discloses a bearing bush type conductive clutch. The bearing bush type conductive clutch is composed of a sub conductive clutch body and a main conductive clutch body, wherein the sub conductive clutch body comprises fixing bolts, a push-type conductive clutch disc convex column, a sub conductive clutch body flange plate, a reset spring, a spring base and cables; the main conductive clutch body comprises a sucked type conductive contact surface groove, fixing bolt grooves, a base push-type conductive clutch disc convex column mounting hole, electrical wires, a main conductive clutch body flange plate and a base. By means of the effective connection arrangement of all the parts of the sub conductive clutch body and the main conductive clutch body, the problems that the manufacturing cost of the conductive clutch is high, a conductive clutch disc is very hot and is severely burnt in the production process, the service life is short, the later period conductivity declines rapidly, and the smooth running of equipment is affected are solved, the usage range is further widened, and the service life is prolonged.

Owner:XUZHOU UNIV OF TECH +1

Production method of high-inflaming-retarding low-smoke halogen-free cable material

InactiveCN102993549BIncrease filling volumeImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesChemical synthesisLinear low-density polyethylene

The invention provides a production method of a high-inflaming-retarding low-smoke halogen-free cable material, belongs to the technical field of cable production, and particularly belongs to the technical field of low-smoke halogen-free cable material production. The production method comprises the steps of uniformly mixing linear low-density polyethylene powder with a silane coupling agent to form a modifying agent; agitating the modifying agent, ore-method magnesium hydroxide, chemical synthesis method magnesium hydroxide, montmorillonoid and zinc borate in a mixer for 10-25 minutes and activating the surfaces of the magnesium hydroxide, the montmorillonoid and the zinc borate; adding an ethylene-vinyl acetate copolymer, linear low density polyethylene, an ethylene-octylene copolymer, a compatilizer, an antioxidant and a lubricating agent into the obtained mixture; and granulating with a double-screw-rod extruder. The production method disclosed by the invention is simple in process and is convenient to produce; the oxygen index of the produced cable material is high and is more than 40; the fireproof property is excellent; and a vertical combustion grade experiment reaches the highest grade, FV-0 grade, and the smoke density is lower than that of the other like products.

Owner:扬州丽薇化学科技有限公司

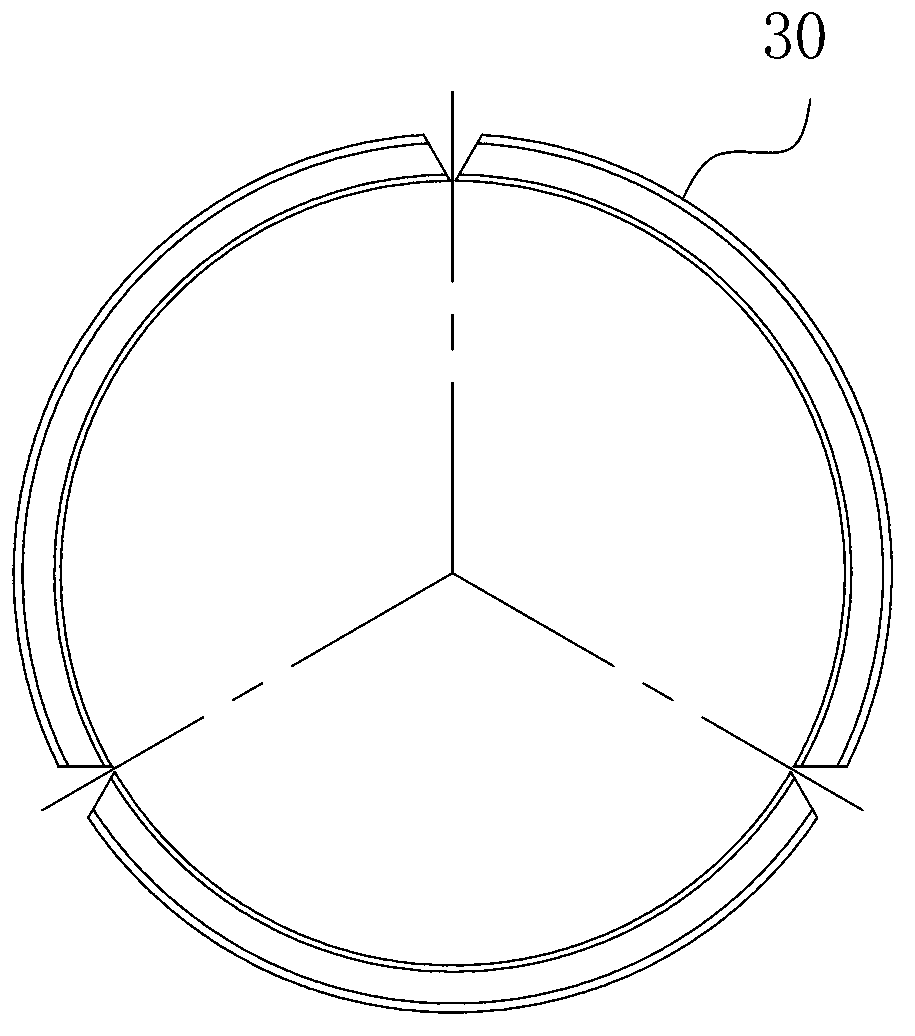

Powder metallurgy bearing for supporting motor rotor in a motor

ActiveCN109099057BEasy to disassembleSolve the problem of troublesome disassemblyRolling contact bearingsShaftsMetallurgyElectric machine

The invention discloses a powder metallurgical bearing for supporting a motor rotor in a motor, and relates to the technical field of motors. An inner ring is composed of two inner arc-shaped rings, the top ends of the two inner arc-shaped rings are connected and fixed in a clamping mode, the bottom ends of the two inner arc-shaped rings are movably hinged, an outer ring is composed of two outer arc-shaped rings, the top ends of the two outer arc-shaped rings are connected and fixed in a clamping mode, the bottom ends of the two outer arc-shaped rings are movably hinged, and the front face ofthe outer ring is provided with convex ends. According to the powder metallurgical bearing for supporting the motor rotor in the motor, the mode of two-part movable installation is adopted, the bearing is conveniently disassembled, the problem of trouble bearing disassembly is solved, replacement is convenient, later maintenance and preservation are facilitated, the labor intensity is reduced, theaxial preload of the rotor bearing is adjusted by elasticity of the convex ends, the drawback of overweight axial overload is avoided, the badness of axial movement is eliminated, meanwhile the noiseproduced by vibration is reduced, and self-lubrication is realized.

Owner:滁州市雪山粮油机械制造有限公司

Aluminum-tin-copper alloy based bearing bush material and preparation method thereof

InactiveCN105734354AEasy to useImprove mechanical propertiesShaftsBearing componentsEnvironmental resistanceManganese

The invention belongs to the technical field of bearing brush materials, and discloses an aluminum-tin-copper alloy based bearing brush material and a preparation method thereof. The material takes in-situ TiB2 particles as an enhanced body, and takes an aluminum-tin-copper alloy as a matrix alloy, wherein volume percentage of the in-situ TiB2 particles is 4.0-12.0%. The preparation method comprises the following steps: (1) melting an aluminum ingot to obtain aluminum melt, and adding a reactant K2TiF6-KBF4 salt mixture and a reactive assistant Na3AlF6-MgCl2 salt mixture into the aluminum melt to obtain the aluminum melt containing in-situ TiB2 particles; (2) adding an aluminum-copper-zinc-manganese intermediate alloy and a tin block into the aluminum melt containing in-situ TiB2 particles to obtain an alloy melt; and (3) taking a NaCl-KCl-CaF2 gas mixture as a refining agent to refine the alloy melt, and casting the alloy melt into a casting mould, thereby obtaining the aluminum-tin-copper alloy based bearing brush material. The aluminum-tin-copper alloy based bearing brush material is excellent in comprehensive functional performance, is low in production cost, is environmentally-friendly, and is pollution-free.

Owner:HENAN MECHANICAL & ELECTRICAL ENG COLLEGE

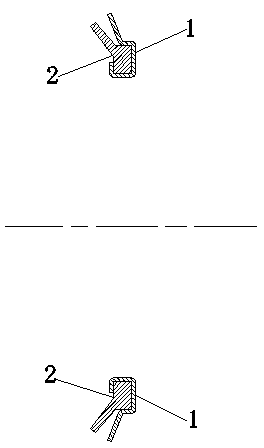

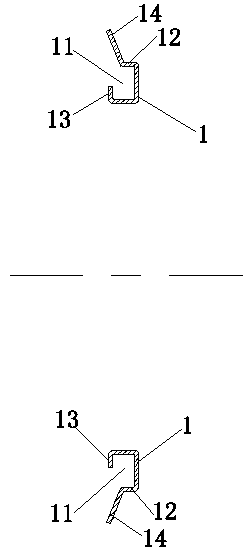

Axial surface oil seal used for high-speed motor

The invention discloses an axial surface oil seal used for a high-speed motor. The axial surface oil seal used for the high-speed motor comprises a circular ring-shaped metal casing and a rubber ring, wherein a circle of groove is formed in the periphery of the inner diameter of the circular ring-shaped metal casing; the one section of the outer edge of the groove bottom upwards extends in a vertical direction to form a circumference of vertical groove wall; the outer edge of the top of the vertical groove wall extends in outward oblique direction to form a sealing protective structure of the rubber ring; a positioning part of the rubber ring is circular ring-shaped, the height of the positioning part is matched with the vertical groove wall of the groove, and the width of the bottom of the positioning part is matched with the width of the groove; the top of the positioning part extends in the outward oblique direction to form a sealing part; and the part between the inner diameter of the bottom of the sealing part and the inner diameter of the top of the positioning part forms a buckling surface of the rubber ring, and the buckling surface is matched with a buckling structure. The axial surface oil seal is applicable to the high-speed motor, and is simple in structure, low in manufacturing cost, long in service life and obvious in effect.

Owner:WUJIANG TIANLONG ELECTRONICS MACHINERY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com