Bridge bearing gliding material and method for preparing the same

A technology of sliding materials and bridge bearings, applied in bridge materials, bridges, bridge construction, etc., can solve the problems of easy cold flow, deformation of sliding plate, large creep, etc., and achieve low friction temperature, not easy to wear, good The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

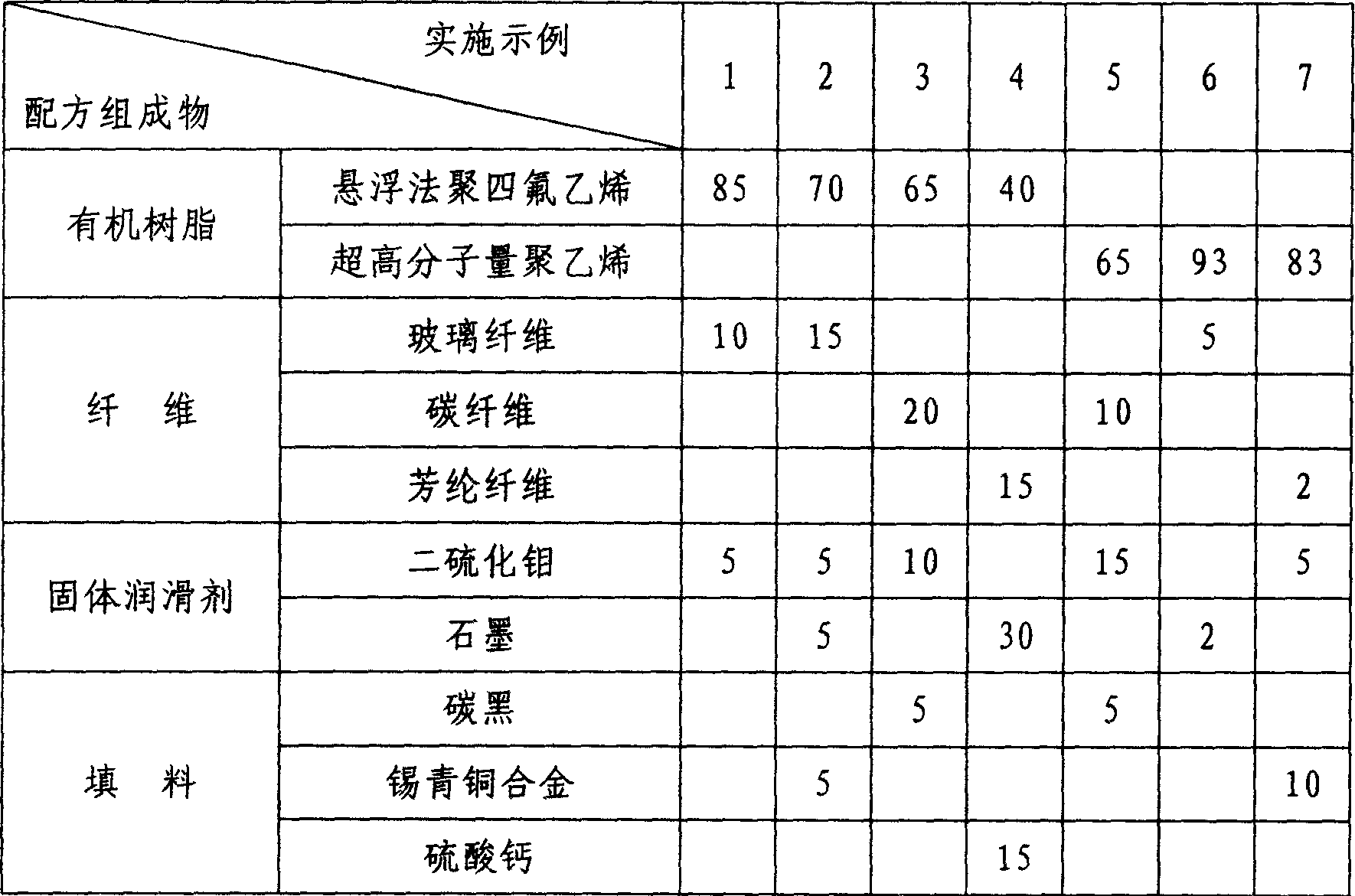

Examples

Embodiment 1

[0017] Example 1: The components in the first row in the formula table are fully mixed in a mechanical mixer as follows, and dried at a temperature of 120-130°C. Then quantitatively put it into the mold, evenly spread the powder, slowly pressurize, the molding pressure is 55MPa, hold the pressure for 2 minutes, and sinter and solidify at 405°C after the pressure is released and the film is released, and the sintering time is 3 hours.

Embodiment 2

[0018] Embodiment 2: each component of column 2 in the implementation formula table is fully mixed as follows, and the technique is the same as in Example 1.

Embodiment 3

[0019] Embodiment 3: each component of the 3rd row in the formula table is fully mixed as follows, and the technique is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com