a metal repair agent

A metal repairing agent, defoaming agent technology, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of scrap parts, equipment shutdown, etc., to achieve long maintenance time, save maintenance costs, improve the effect of matching clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Preparation of Metal Restoration Agent

[0020] The metal restoration agent prepared by the present invention can be formulated according to the following raw material components:

[0021] 5 parts of zinc dialkyldithiophosphate, 20 parts of calcium stearate, 3 parts of nano-magnesium oxide, 3 parts of nano-silicon dioxide, 1 part of polycarbon elastic resin, 2 parts of accelerator, 1 part of defoamer, amide 6 parts of base amine curing agent, 1.2 parts of ammonium sulfate, 7 parts of gull gum, 1.5 parts of nano-silver, 3 parts of polyphenol, and 7 parts of low-density polyethylene.

[0022] During specific preparation, the raw material components can also be:

[0023] 9 parts of zinc dialkyl dithiophosphate, 30 parts of calcium stearate, 8 parts of nano magnesium oxide, 8 parts of nano silicon dioxide, 5 parts of polycarbon elastic resin, 5 parts of accelerator, 3 parts of defoamer, amide 8 parts of base amine curing agent, 4 parts of ammonium sulfate, 11 pa...

Embodiment 2

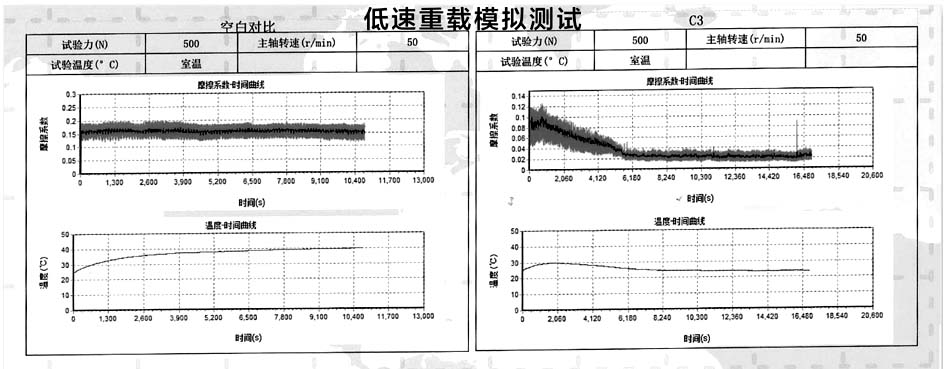

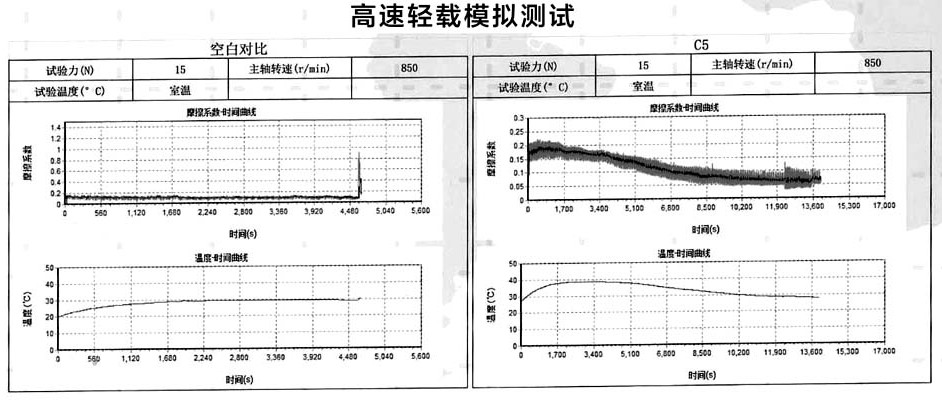

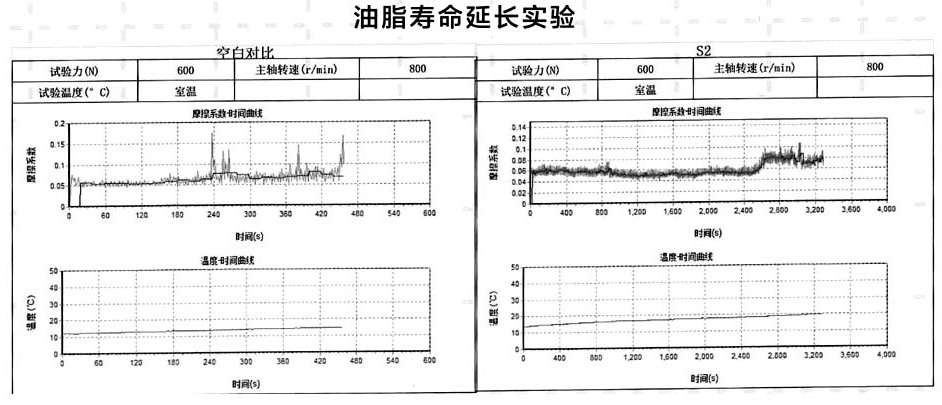

[0027] Embodiment 2 Effect test of the metal restoration agent of the present invention

[0028] 1. Equipment life test

[0029] Taking the rolling bearing as the base, group B added the metal repair agent of the present invention to the lubricating liquid (with 500SN base oil for reconciliation, the addition amount is 8% of the total amount of lubricating liquid), group A is the comparative example (no metal repair agent) . The test results are shown in Table 1 below.

[0030] Table 1

[0031]

[0032] It can be seen from the data in Table 1 that one set of bearings failed when Group A operated for 127 hours, 140 hours, 270 hours, 275 hours, 301 hours, 323 hours and 370 hours, and only one set of bearings remained in normal operation at 390 hours ; However, after 400 hours of accumulative operation in Group B, no failed bearings occurred, and all eight sets of test bearings operated well. It is proved that the metal restoration agent of the present invention can prolon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com