High-shear ultra-fine pulverizing machine

An ultra-fine pulverizer and high shear technology, applied in grain processing and other directions, can solve the problems of long friction times and friction time, slow work efficiency, etc., and achieve the effect of reducing friction temperature, reducing denaturation and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

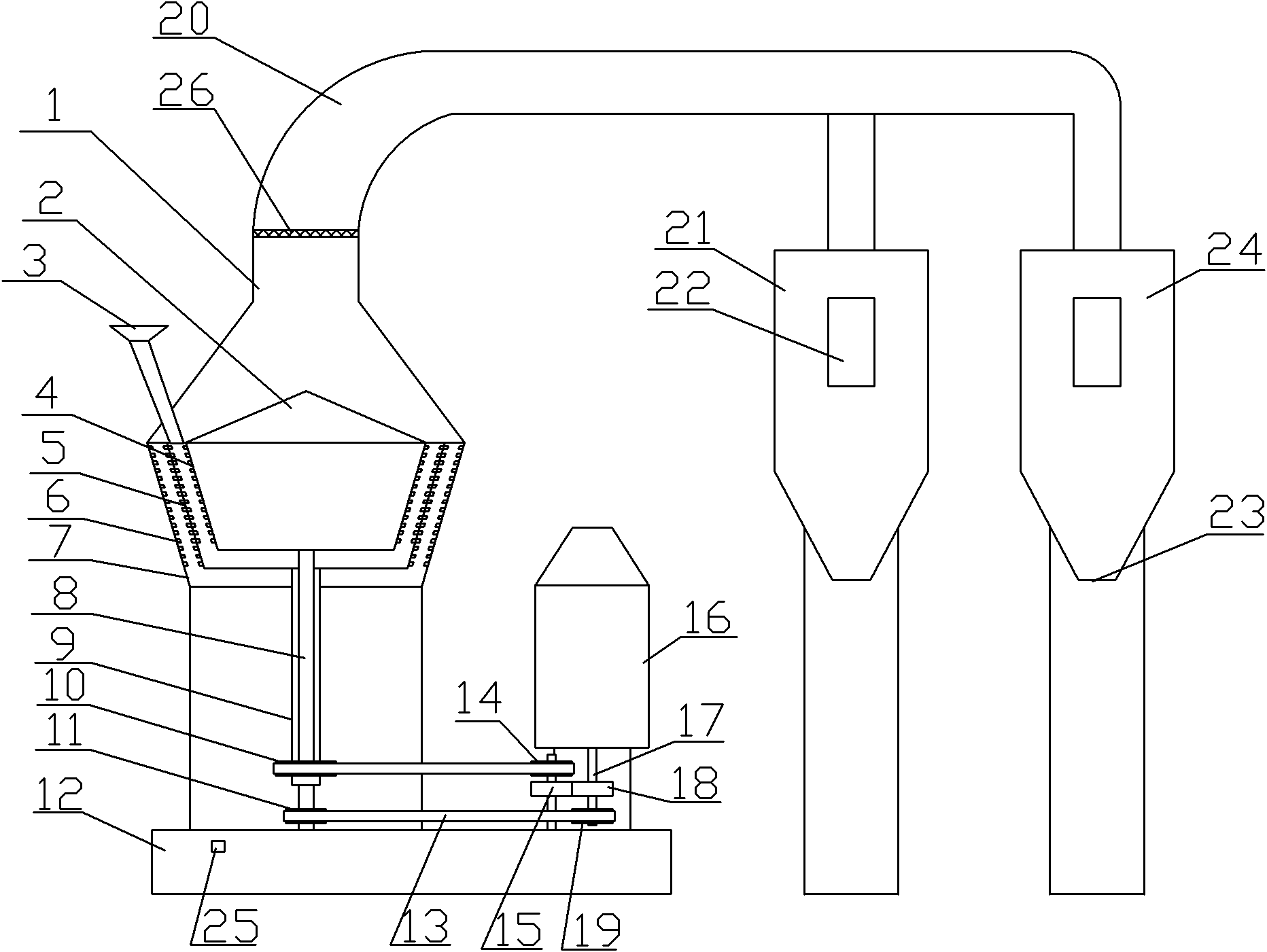

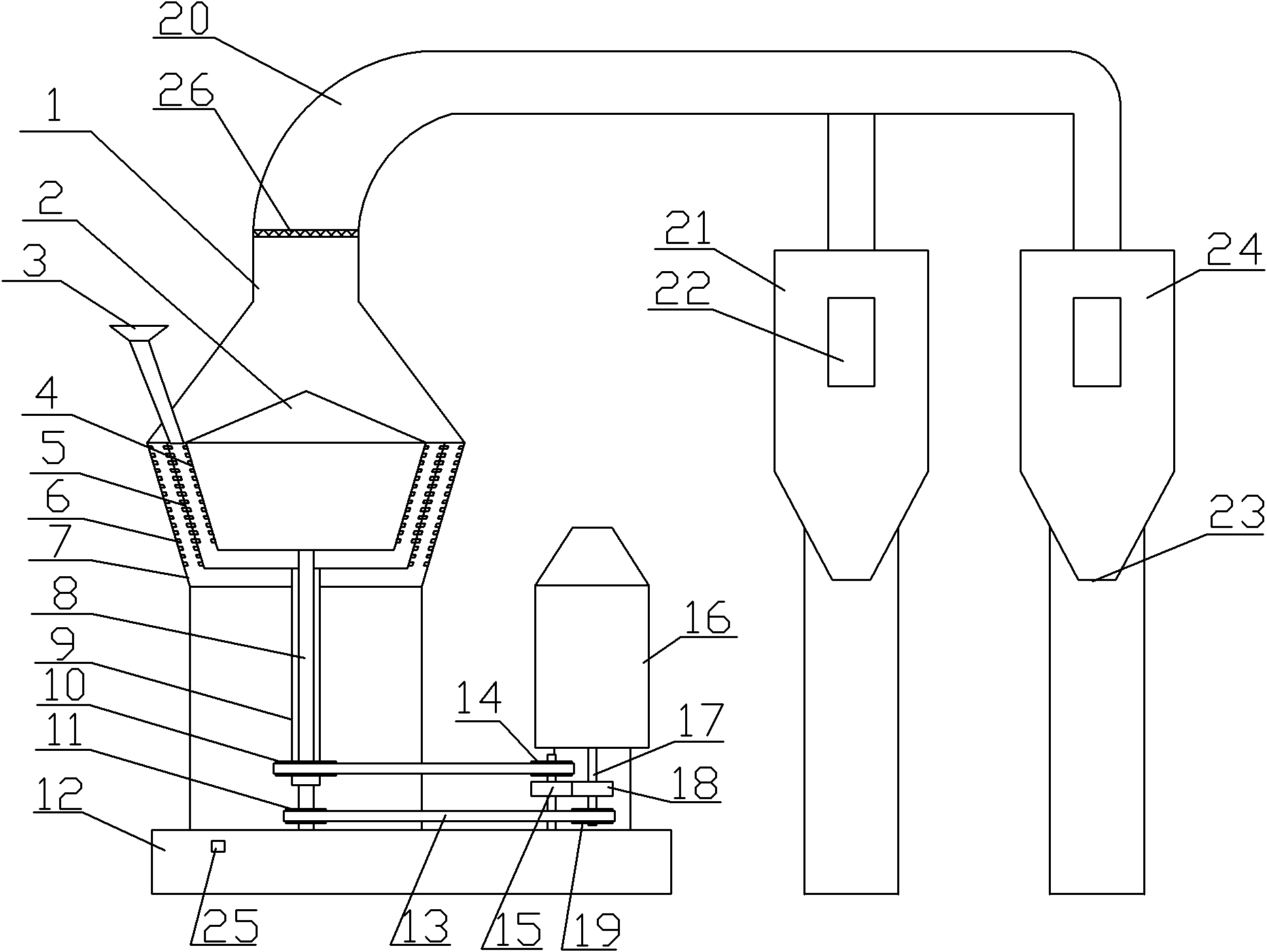

[0010] Refer to the attached figure 1 The high-shear ultrafine pulverizer of the present invention will be described in detail below.

[0011] The structure of the high-shear ultrafine pulverizer of the present invention includes a collection tube 1, a delivery pipe 20 and a storage bin. The collection tube 1 is arranged on the top of the frame 12, and the top of the collection tube 1 A mesh screen 26 is provided, the collection cylinder 1 includes the first rotor 4, the second rotor 5 and the fixed outer bin 7, the outer side wall of the first rotor 4, the two sides of the second rotor 5 and the fixed outer bin The inside of the bin 7 is respectively provided with stators 6, the upper part of the first rotor 4 is provided with a top cover 2, the second rotor 5 is grid-shaped, and the first rotor 4 and the second rotor 5 pass through The transmission mechanism is connected to the motor 16 arranged on the frame 12, the frame 12 is provided with a power supply 25, the power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com