Intelligent flexible bran and fine broken rice separator

A chaff separation and flexible technology, applied in grain processing, application, grain pod removal, etc., can solve the problems of high equipment investment cost and single function, and achieve the effect of convenient operation, strong functionality, and lower friction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the embodiments of the accompanying drawings.

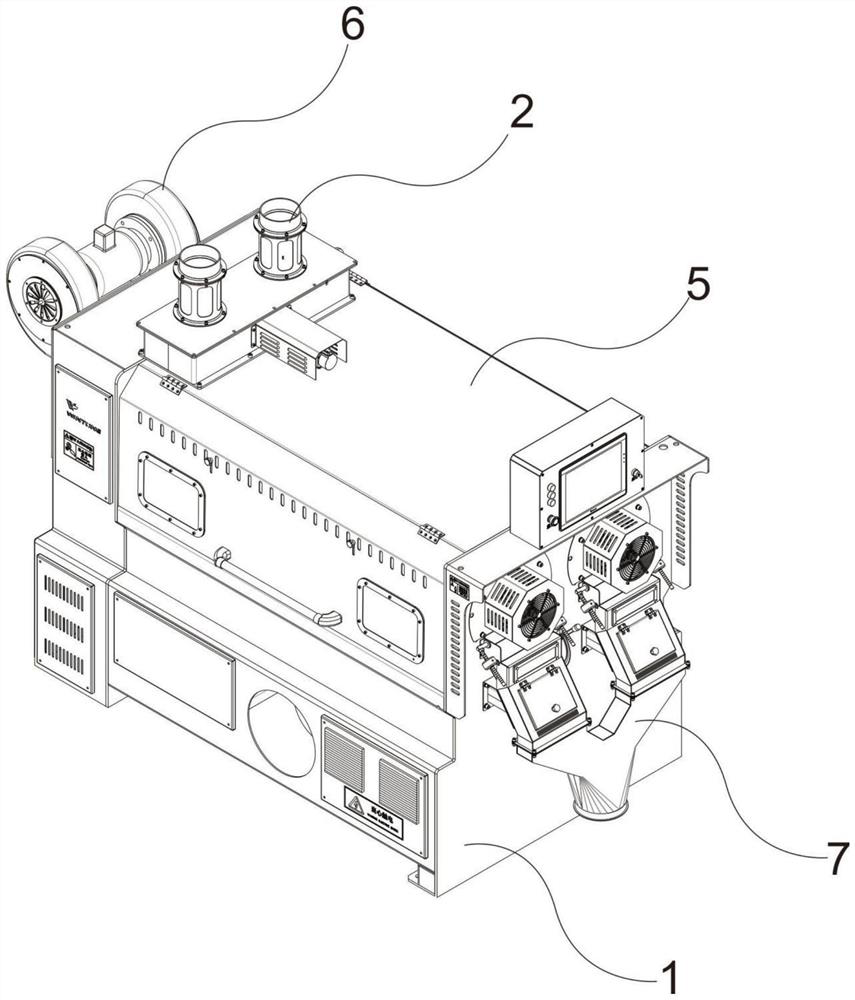

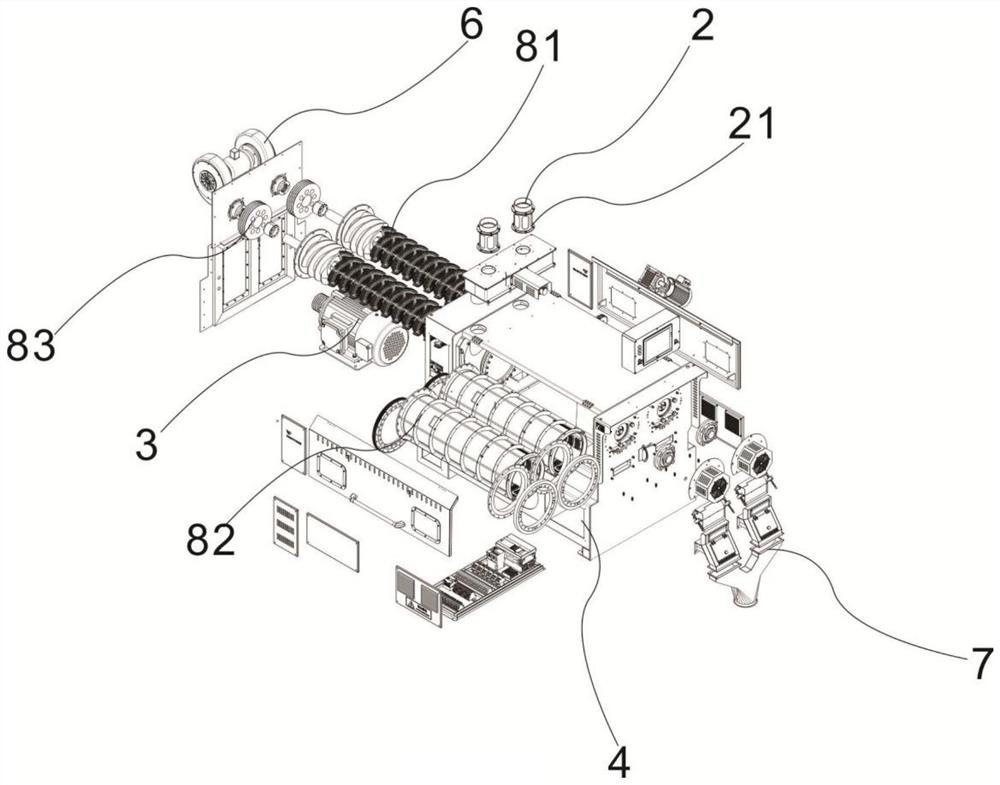

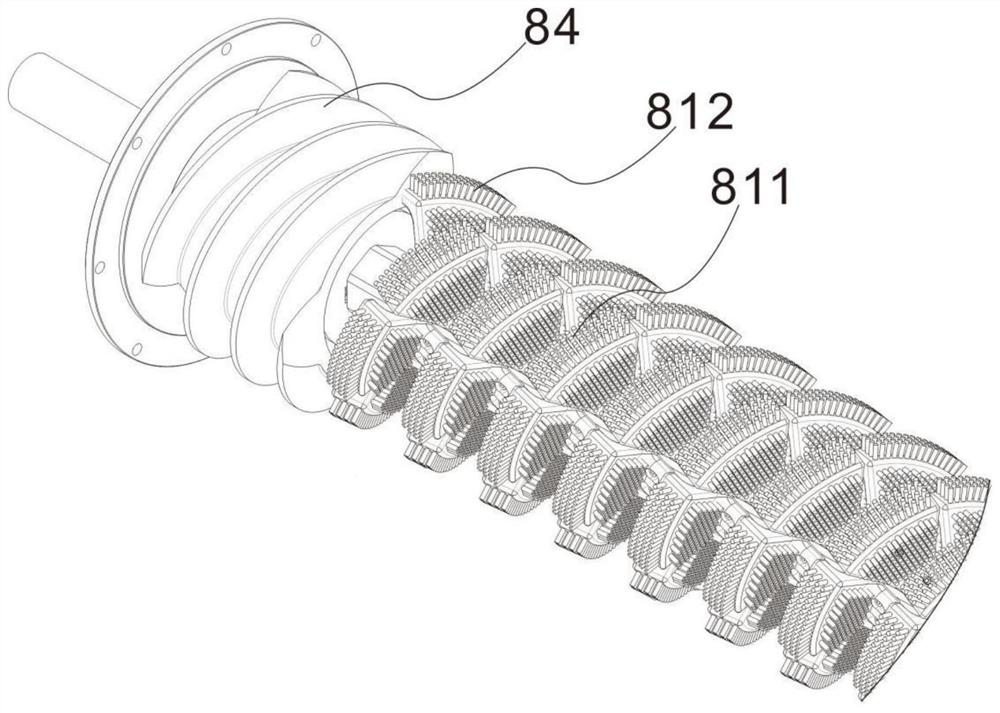

[0023] Such as Figure 1-4 As shown, a kind of intelligent flexible chaff separator, it comprises frame 1, and the rubbing system that is located on frame 1, blower 6, feed port 2, discharge system 7, motor 3, chaff channel 4 , casing 5, described polishing system comprises rotor 81, rotary screening system 82, passive belt pulley 83, described rotor 81 is a rotating shaft, and rotating shaft is fixedly installed with passive belt pulley 83 at the afterbody, and passive belt pulley 83 passes belt It is connected with the motor 3, and the rotor is driven by the motor 3 to rotate. The rotary sieve system 82 is a cylindrical tubular structure, which is set on the outside of the rotor 81 and fixedly installed on the frame 1. The feed port 2 is located at The upper part of the rubbing system, the discharge system 7 includes a discharge port 71, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com