Regulation test method for friction temperature, and pin sample for the same

A test method and friction body technology, applied in temperature control, machine/structural component testing, thermometers, etc., to achieve the effect of controlling friction and wear performance, improving friction and wear performance, and the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

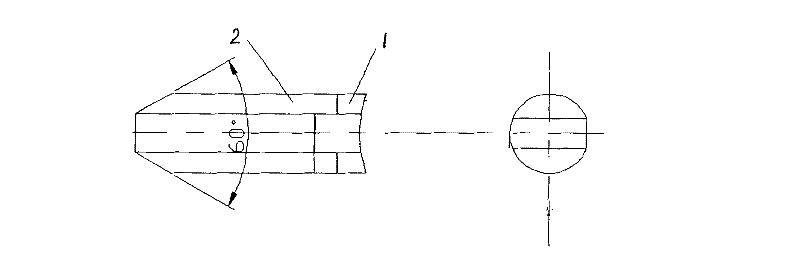

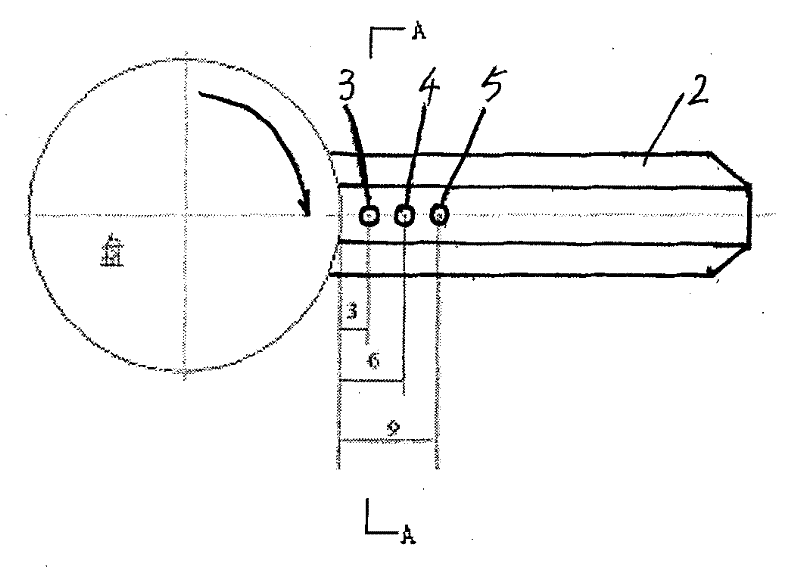

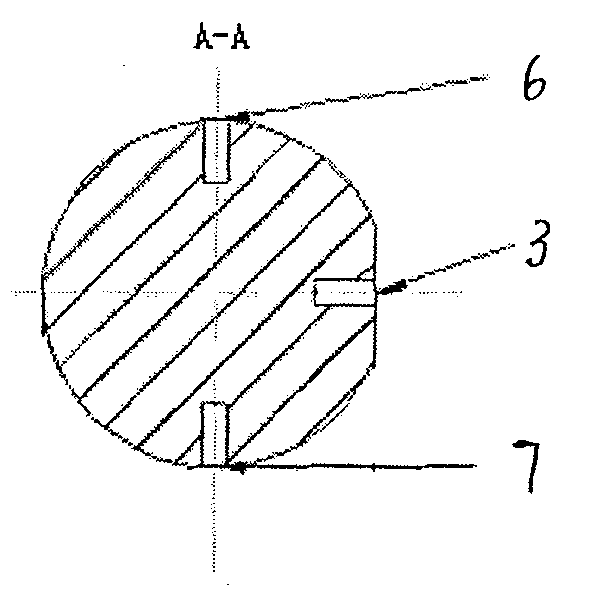

[0029] like figure 1 , figure 2 , image 3 As shown, the pin sample structure used in the method of this embodiment consists of a friction body 1 and a pin body 2 in the rear section. The friction body 1 and the pin body 2 have different thermal conductivity, and the friction body 1 and the pin body 2 are mechanically inlaid and matched as One-piece structure, in order to ensure that the interfaces are in contact with each other during inlay, the interference fit is used for assembly, and the interference amount is 0.15mm. There are temperature measuring holes for placing thermocouples in the radial and axial directions of the pin sample, and the thermocouple monitoring test method is used for testing. Since the temperature of the friction surface when the friction pair slides is very unstable, the present invention adopts the method of setting a temperature measuring hole on the pin sample and installing a nickel-chromium-nickel-silicon thermocouple to measure the tempera...

Embodiment 2

[0034] The forced thermal conduction combined pin samples composed of Ti6Al4V, 45 steel, red copper and Ti6Al4V mechanical inlay with different thermal conductivity were used for comparative experiments.

[0035] The results show that the friction temperature of Ti6Al4V-Copper with the best thermal conductivity is the lowest, and the friction temperature of Ti6Al4V-Ti6Al4V with the worst thermal conductivity is the highest ( Image 6 ). If the friction temperature and thermal conductivity of the Ti6Al4V-Ti6Al4V pin sample are compared with the base 1, the relative friction temperature value and the relative thermal conductivity value of Ti6Al4V-Copper and Ti6Al4V-Steel show an inverse relationship ( Figure 7 ). The higher the thermal conductivity, the lower the friction temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com