Intelligent flexible rice rubbing and polishing machine

A rice, flexible technology, applied in grain finishing, grain processing, application, etc., can solve the problems of the influence of rice protein composition, poor rubbing effect, affecting the taste and nutrition of rice, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further illustrated in conjunction with the embodiments of the drawings.

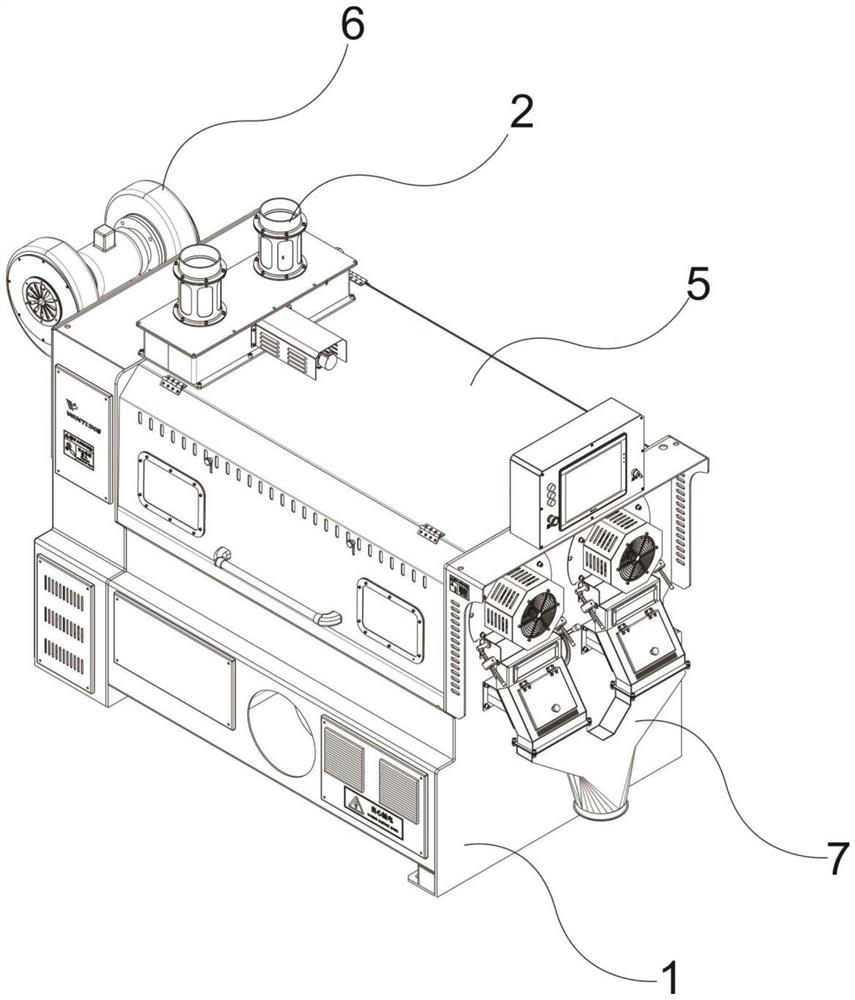

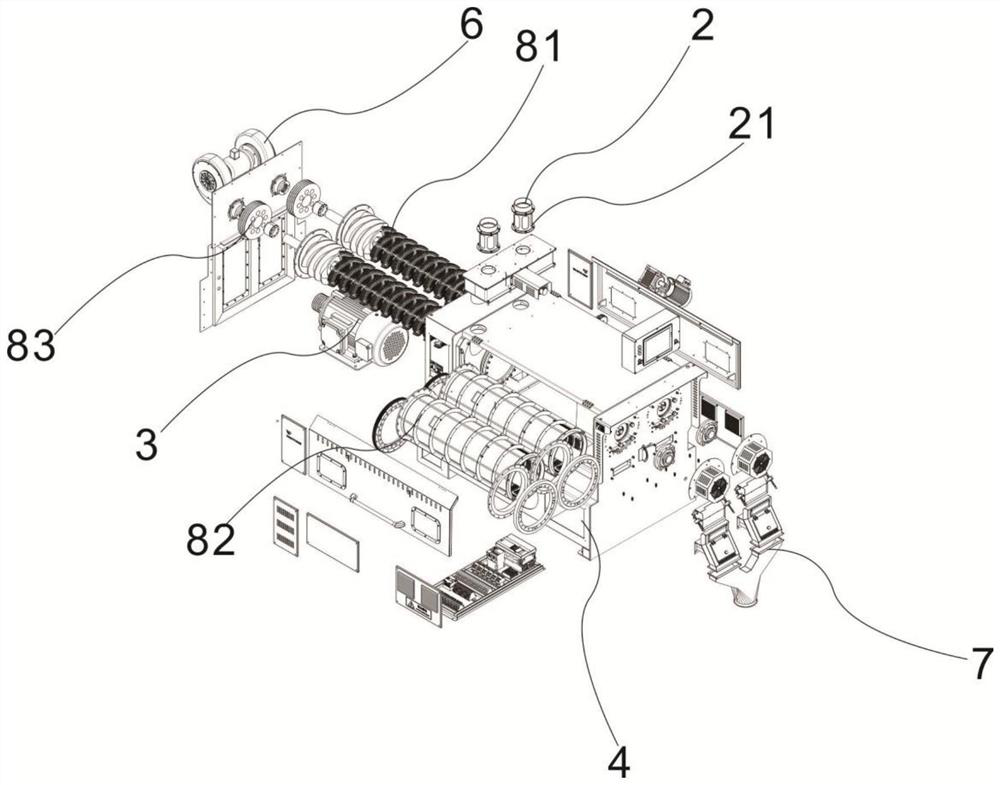

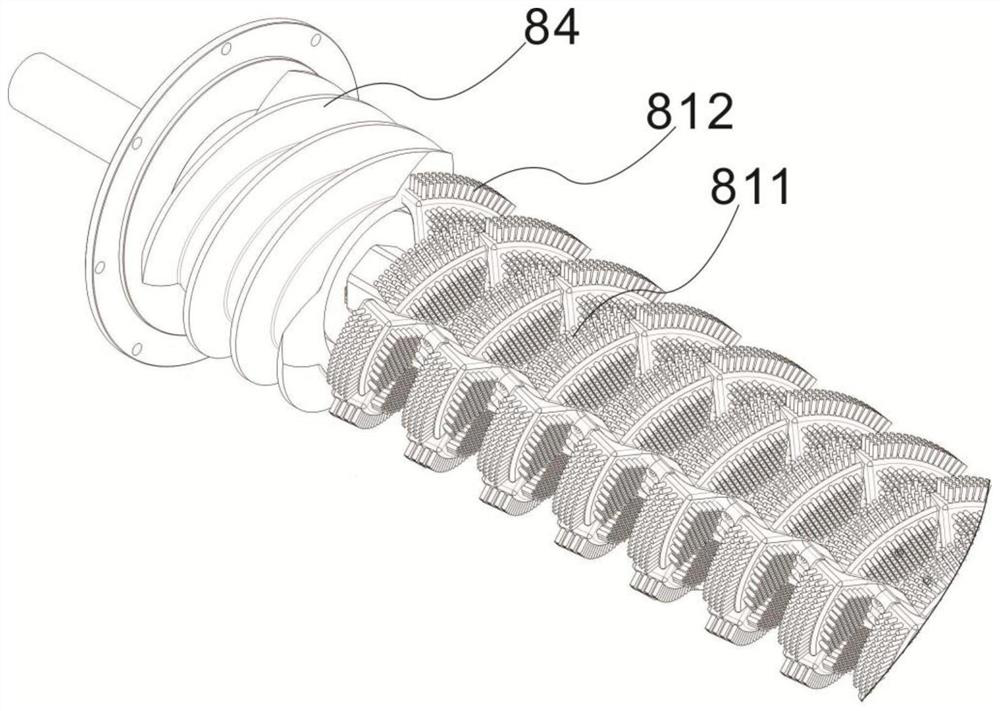

[0019] like Figure 1-4 As shown, a smart flexible rice light, which includes a rack 1, as well as a light-like system, a blower 6, a feed port 2, an assembly system 7, a motor 3, a bran channel 4 The casing 5 includes a rotor 81, a rotary screen system 82, a passive pulley 83, and the rotor 81 is a rotating shaft, the rotating shaft is fixedly mounted on the tail, and the passive pulley 83 is attached, the passive pulley 83 passes through the belt The motor 3 is connected to the motor 3, the rotary screen system 83 is a cylindrical cylindrical structure, which is disposed outside the rotor 81, fixed to the rack 1, and the feed port 2 is located The upper portion of the light system, the discharge system 7 includes a discharge port 71, mounted on the tail of the rotor 81, the outer side of the rotary screening system 82, and the mesh size is set to enable rice bran. The rice c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com