High-yield processing method of ultra-fine crystal magnesium alloy thin plate

A processing method and technology for magnesium alloys, applied in metal rolling and other directions, can solve the problems of small processing strain and uneven microstructure of ultra-fine-grained magnesium alloys, achieve good strength and plasticity, reduce edge cracks, and reduce energy consumption. and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This example uses ZK60 (Mg-6wt%Zn-0.5wt%Zr) magnesium alloy as the test material.

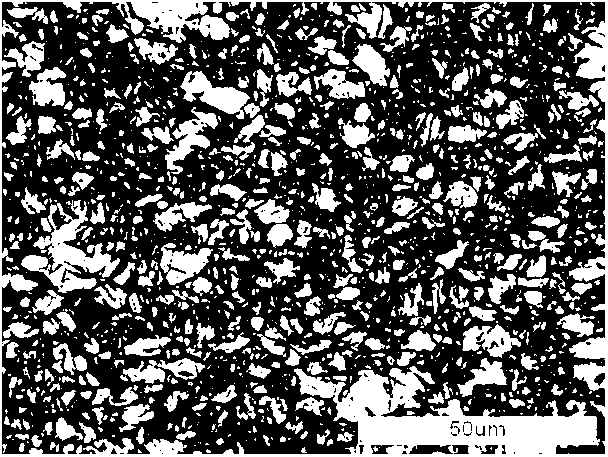

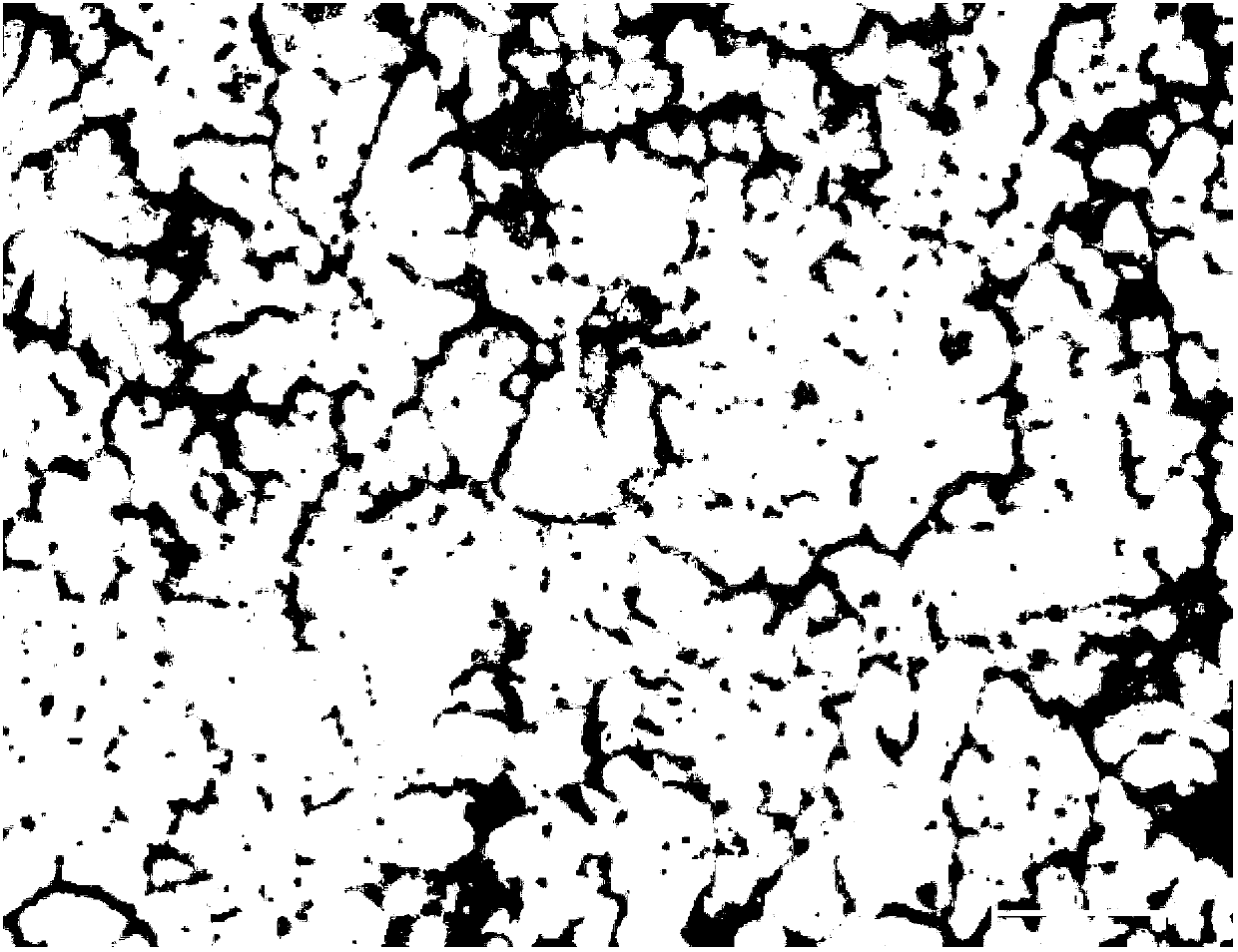

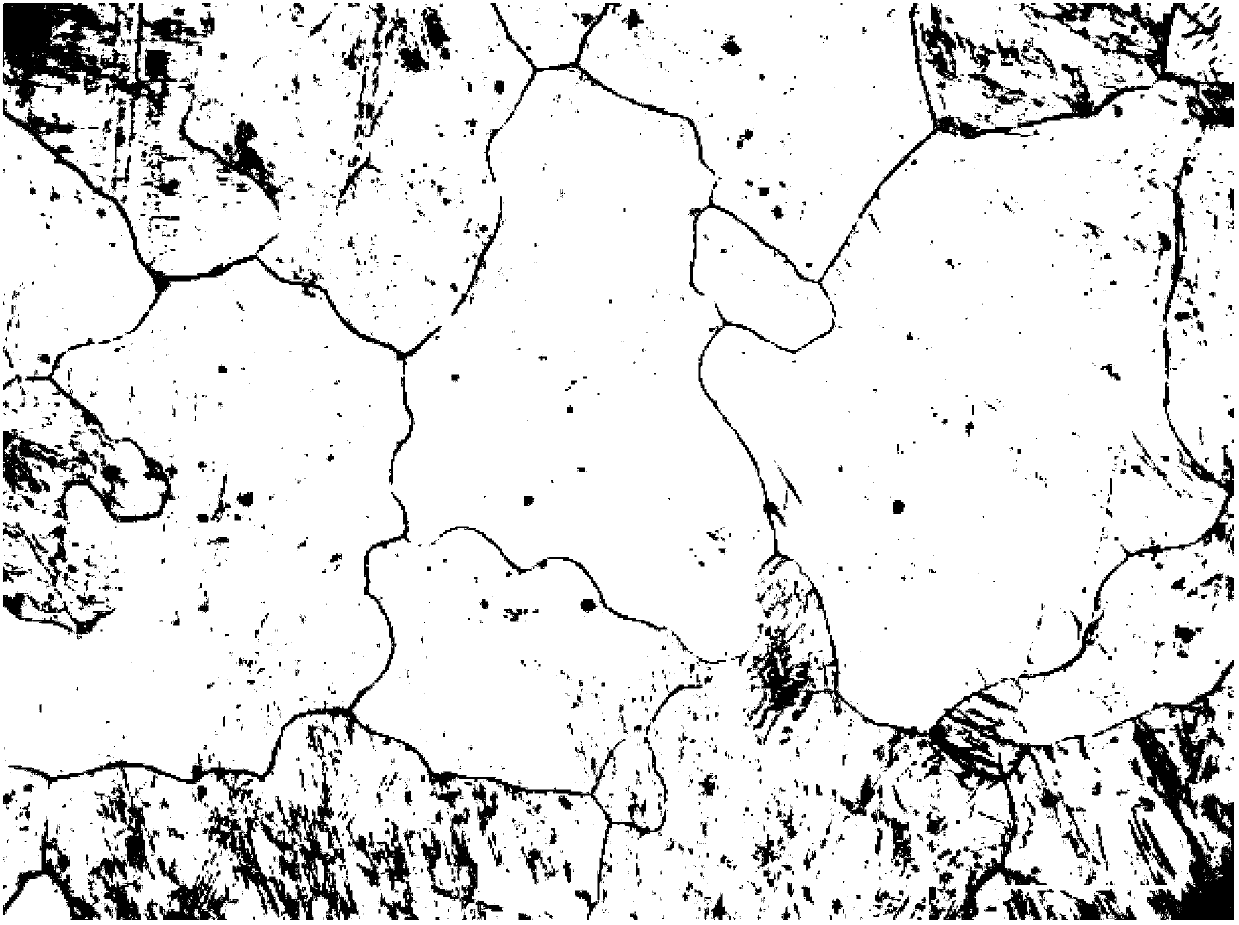

[0033] First, the as-cast ZK60 magnesium alloy was wire-cut into a cuboid block of 20mm×20mm×40mm, and then placed in a heating furnace and heated to 420°C for 16h for solution treatment. figure 1 It is the metallographic structure of as-cast ZK60, showing coarse dendrites; after solid solution treatment, the dendrite grain boundaries disappear, and the grains grow, with an average grain size of about 150 microns, such as figure 2 . Optionally, homogenization heat treatment can also be performed at 420° C. for 12 hours. The solution-treated block was placed in a mold preheated to 300°C for 30 minutes, and multi-pass equal channel angular extrusion was performed on it. After 12 passes of extrusion, the crystal grains are obviously refined, the average particle size is less than 5 microns, and the structure is uniform, such as image 3 shown.

[0034] Cut the sample after equal channe...

Embodiment 2

[0037] In this embodiment, ZE41 (Mg-4%Zn-1.5%Y-Zr) magnesium alloy is used.

[0038] The difference between the processing technology and Example 1 is: the holding temperature in the first step is 450°C, and the holding time is 80min. 350°C, rolling reduction of 40% per pass, and finally a thin plate with a thickness of 0.2 mm. After the magnesium alloy is processed, the tensile strength of the obtained magnesium alloy sheet can reach more than 300MPa, and the finished product rate can reach more than 85%.

[0039]

Embodiment 3

[0041] In this embodiment, ZE41 (Mg-4%Zn-1.5%Y-Zr) magnesium alloy is used.

[0042] The difference between the processing technology and Example 1 is: the holding temperature in the first step is 400°C, and the holding time is 120min. At this temperature, the number of extrusions in the equal-channel angular extrusion process is 10 passes, and the temperature during rolling is 100°C, rolling reduction of 20% per pass, and finally a thin plate with a thickness of 0.2 mm. After the magnesium alloy is processed, the tensile strength of the obtained magnesium alloy sheet can reach more than 320MPa, and the finished product rate can reach more than 80%.

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com