Continuous rolling process method with tension for high silicon steel

A high-silicon steel and tension technology, applied in the direction of tension/pressure control, metal rolling, temperature control, etc., can solve the problems of poor plate shape and flatness, and achieve the effects of less edge cracks, excellent plate shape, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

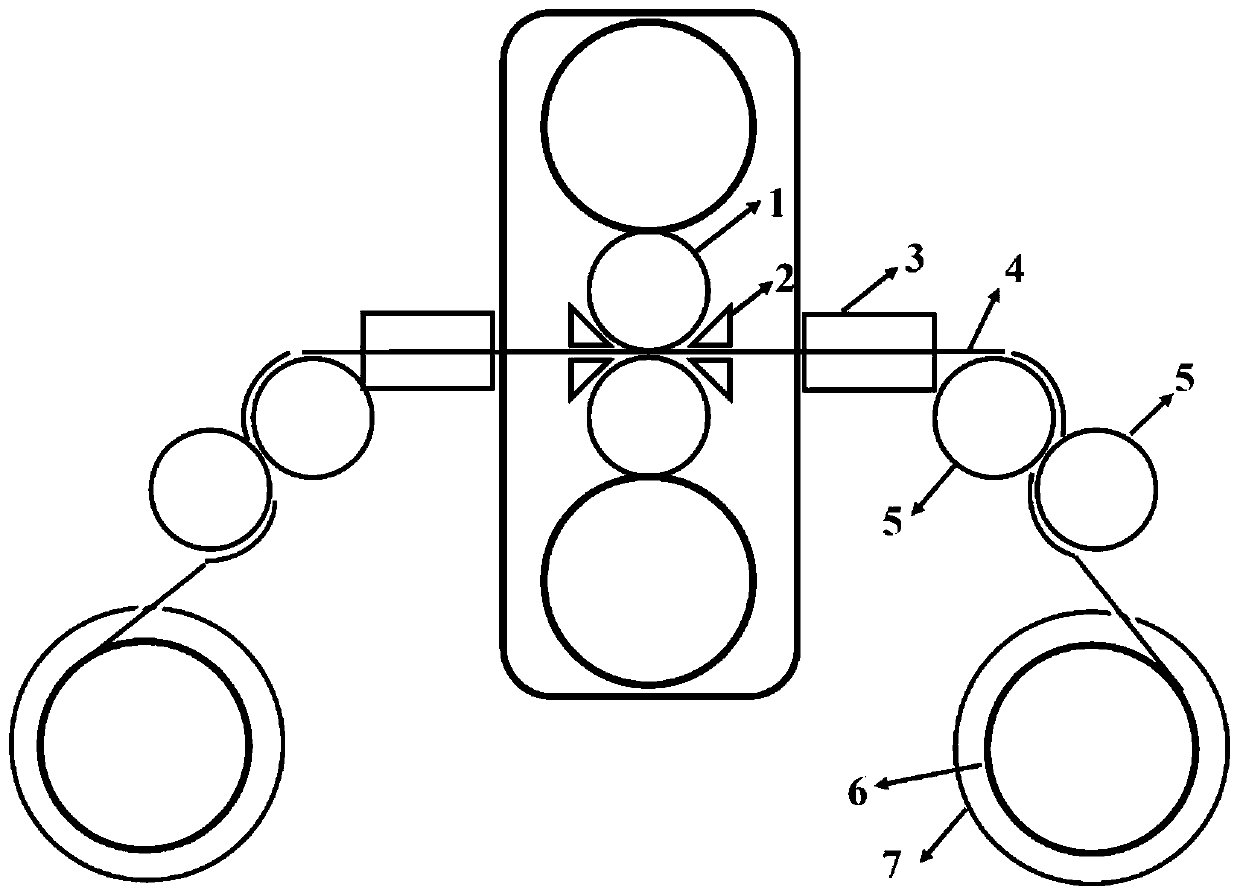

Image

Examples

Embodiment 1

[0033] The composition of the high-silicon steel plate is (mass percentage): Si content is 6.49%, the balance is iron and unavoidable impurities, and the thickness is 1.8mm.

[0034] S1: Welding: Laser welding high silicon steel and stainless steel, welding the laser welded high silicon steel plate and the leader tape for coiling together;

[0035] S2: Preheating the roll: lift the roll, and use the roll furnaces on both sides of the roll to preheat the roll, and the preheating temperature is 180°C;

[0036] S3: The open hearth furnace and coil furnace on one side are heated up, and induction heating works: roll the leader tape into the coil furnace, adjust the temperature of the coil furnace and flat furnace on the one side to be 800°C, and the heating power of the induction equipment is oscillating current 25A, The heat preservation power current is 17.6A, and the temperature is 800°C;

[0037] S4: Coiling: the high-silicon steel is assisted by open hearth furnace and induc...

Embodiment 2

[0043] The composition of the high-silicon steel plate is (mass percentage): Si content is 6.51%, the balance is iron and unavoidable impurities, and the thickness is 1.1 mm.

[0044] S1: Welding: Laser welding high silicon steel and stainless steel, welding the laser welded high silicon steel plate and the leader tape for coiling together;

[0045] S2: Preheating the roll: lift the roll, and use the roll furnaces on both sides of the roll to preheat the roll, and the preheating temperature is 180°C;

[0046] S3: The open hearth furnace and the coil furnace on the one side are heated up, induction heating works: the leader tape is drawn into the coil furnace, the temperature of the coil furnace and the flat furnace on the one side is adjusted to 700°C, the heating power of the induction equipment is oscillating current 25A, The heat preservation power current is 17.6A, and the temperature is 700°C;

[0047] S4: Coiling: the high-silicon steel is assisted by open hearth furnac...

Embodiment 3

[0053] The composition of the high-silicon steel plate is (mass percentage): Si content is 6.43%, the balance is iron and unavoidable impurities, and the thickness is 0.5mm.

[0054] S1: Welding: Laser welding high silicon steel and stainless steel, welding the laser welded high silicon steel plate and the leader tape for coiling together;

[0055] S2: Preheating the roll: lift the roll, and use the roll furnaces on both sides of the roll to preheat the roll, and the preheating temperature is 180°C;

[0056] S3: The open hearth furnace and coil furnace on one side are heated up, and induction heating works: roll the leader tape into the coil furnace, adjust the temperature of the coil furnace and flat furnace on the one side to be 350°C, and the heating power of the induction equipment is 25A. The heat preservation power current is 17.6A, and the temperature is 350°C;

[0057] S4: Coiling: the high-silicon steel is assisted by open hearth furnace and induction heating equipme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com