Method for preparing high-silicon electric steel band material through rolling at medium and low temperature

A technology of high-silicon electrical steel and low-temperature rolling, which is applied in the medium and low-temperature preparation and processing technology of high-performance, low-plasticity and difficult-to-process alloy strips, and in the field of preparation of high-silicon electrical steel strips, to reduce rolling edge cracks and improve processing Efficiency and yield, and the effect of improving organizational structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

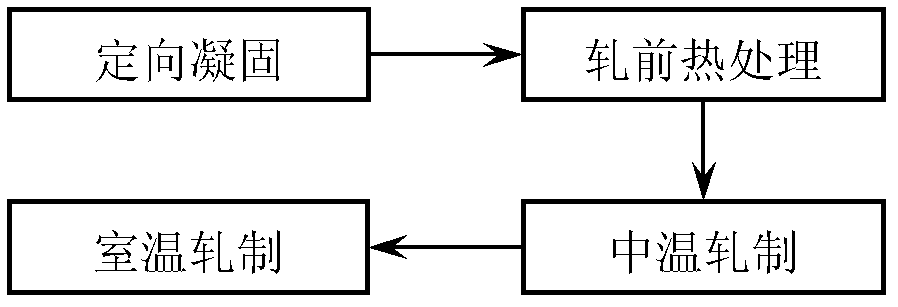

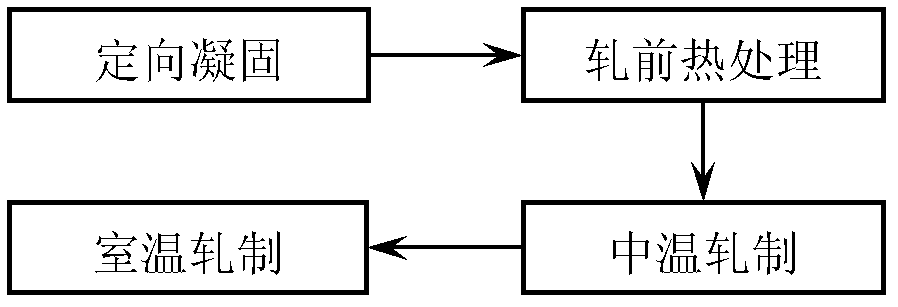

Method used

Image

Examples

Embodiment 1

[0030] Example 1: Wire-cut directional solidified billets into slabs and roll them after heat treatment

[0031] (1) Directional solidification: The vacuum-melted Fe-6.5Si-0.01B alloy billet was prepared into a columnar grain structure with a strong orientation and a diameter of 30mm by using the method of zone melting and directional solidification.

[0032] (2) Heat treatment before rolling: heat the directionally solidified billet at a rate of 15°C / min to 900°C for 1 hour, then oil quench to room temperature, and the cooling rate is about 200°C / s; heat the quenched billet at 300°C for 10 minutes Air cooling, stress relief annealing;

[0033] (3) Medium-temperature rolling: the high-silicon electrical steel billet after heat treatment before rolling is rolled at 400°C for 20 minutes, and the rolling speed is 20m / min; the deformation of the alloy is strictly controlled at 5%~20%. The final thickness of the medium-temperature rolled plate is 1 mm; after rolling, it is air-...

Embodiment 2

[0036] Embodiment 2: directionally solidified slab is rolled after treatment

[0037] (1) Directional solidification: The vacuum-melted Fe-6.5Si alloy billet was prepared into a columnar crystal slab with a strong orientation, a width of 24mm, and a thickness of 12mm by using the method of zone melting and directional solidification.

[0038] (2) Heat treatment before rolling: heat the directionally solidified slab to 1000°C at a rate of 15°C / min and keep it warm for 1 hour, then oil quench to room temperature, and the cooling rate is about 200°C / s, keep the quenched blank at 350°C for 15 minutes and then air cool , for stress relief annealing;

[0039] (3) Medium-temperature rolling: the high-silicon electrical steel billet after heat treatment before rolling is rolled at 450°C for 20 minutes, and the rolling speed is 20m / min; the deformation of the alloy is strictly controlled at 5%~20%. The final thickness of the medium-temperature rolled plate is 2mm; after rolling, it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com